Lithium ion battery cathode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems such as poor cycle performance, large volume changes, and limitations in practical applications, and achieve serious volume expansion, simple preparation methods, and improved Effect of charge-discharge cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

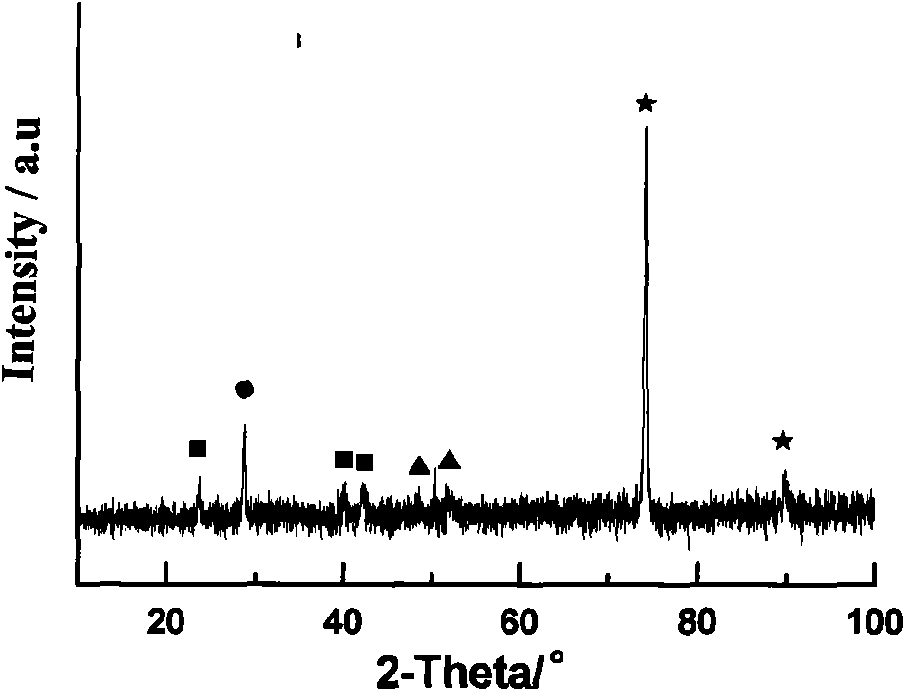

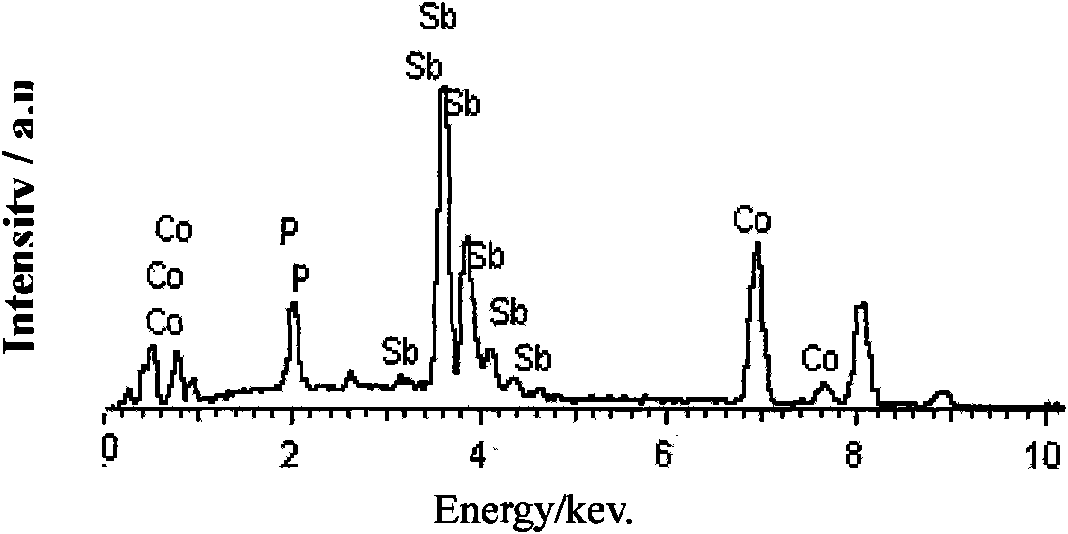

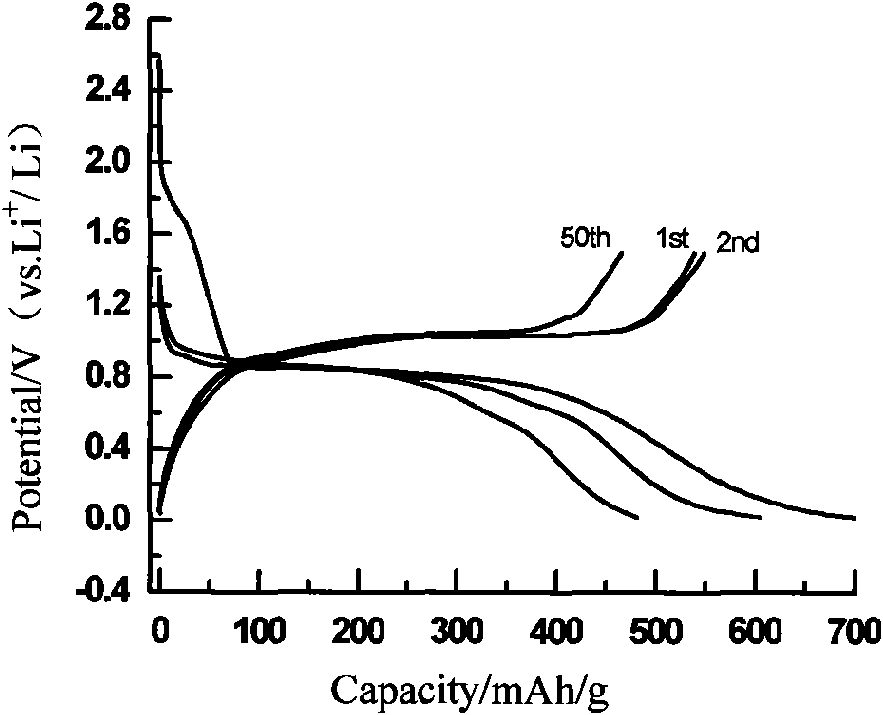

[0022] Preparation of antimony-cobalt-phosphorus alloy negative electrode material: Dissolve 10g of boric acid in 150ml of deionized water, add 15g of ammonium chloride, 5g of ammonium bromide and 10g of sodium hypophosphite under stirring, and adjust with dilute hydrochloric acid with a mass fraction of 5%. After the pH=1.5, 4g of cobalt chloride and 2g of antimony potassium tartrate were added, and the volume was adjusted to 250ml to obtain an electrodeposition solution. The mass ratio of the components is boric acid: ammonium chloride: ammonium bromide: sodium hypophosphite: cobalt chloride: antimony potassium tartrate=1:1.5:0.5:1.0:0.4:0.2. At room temperature, at 25.0A / dm 2 And under the condition of stirring, the antimony-cobalt-phosphorus alloy negative electrode material was obtained by electrodepositing for 20 minutes with plane copper as the current collector. XRD( figure 1 ) results show that the phase of the material is CoSb 3 , Sb and Co 2 P, EDS results ( f...

Embodiment 2

[0025] Preparation of antimony-cobalt-phosphorus alloy negative electrode material: Dissolve 10g of boric acid in 150ml of deionized water, add 5g of ammonium chloride, 2g of ammonium bromide and 2.5g of sodium hypophosphite under stirring, and use dilute hydrochloric acid with a mass fraction of 8% After adjusting the pH=2.0, 3 g of cobalt chloride and 0.2 g of antimony potassium tartrate were added respectively, and the volume was adjusted to 250 ml to obtain an electrodeposition solution. The mass ratio of the components is boric acid: ammonium chloride: ammonium bromide: sodium hypophosphite: cobalt chloride: antimony potassium tartrate=1:0.5:0.2:0.25:0.3:0.02. At room temperature, at 4.5A / dm 2 And under the condition of stirring, the antimony-cobalt-phosphorus alloy negative electrode material was obtained by electrodepositing for 20 minutes with plane copper as the current collector. XRD results show that the material phase is CoSb 3 , Sb and Co 2 P, EDS results show ...

Embodiment 3

[0027]Preparation of antimony-cobalt-phosphorus alloy negative electrode material: Dissolve 10g of boric acid in 150ml of deionized water, add 15g of ammonium chloride, 8g of ammonium bromide and 10g of sodium hypophosphite under stirring, and adjust with dilute hydrochloric acid with a mass fraction of 4%. After the pH=1.0, 4g of cobalt chloride and 1g of potassium antimony tartrate were added respectively, and the volume was adjusted to 250ml to obtain an electrodeposition solution. The mass ratio of the components is boric acid: ammonium chloride: ammonium bromide: sodium hypophosphite: cobalt chloride: antimony potassium tartrate=1:1.5:0.8:1.0:0.4:0.1. At room temperature, at 10A / dm 2 And under the condition of stirring, the antimony-cobalt-phosphorus alloy negative electrode material was obtained by electrodepositing for 10 minutes with plane copper as the current collector. XRD results show that the material phase is CoSb 3 , Sb and Co 2 P, EDS results show that its m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com