Waste water integrated treatment method of paraquat produced by cyanamideprocess

A treatment method and paraquat technology, applied in the field of integrated treatment of herbicide wastewater, can solve problems such as failure to recover useful substances, waste of resources, large investment, etc., and achieve the effects of reducing wastewater treatment costs, reducing pollution, and reducing pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

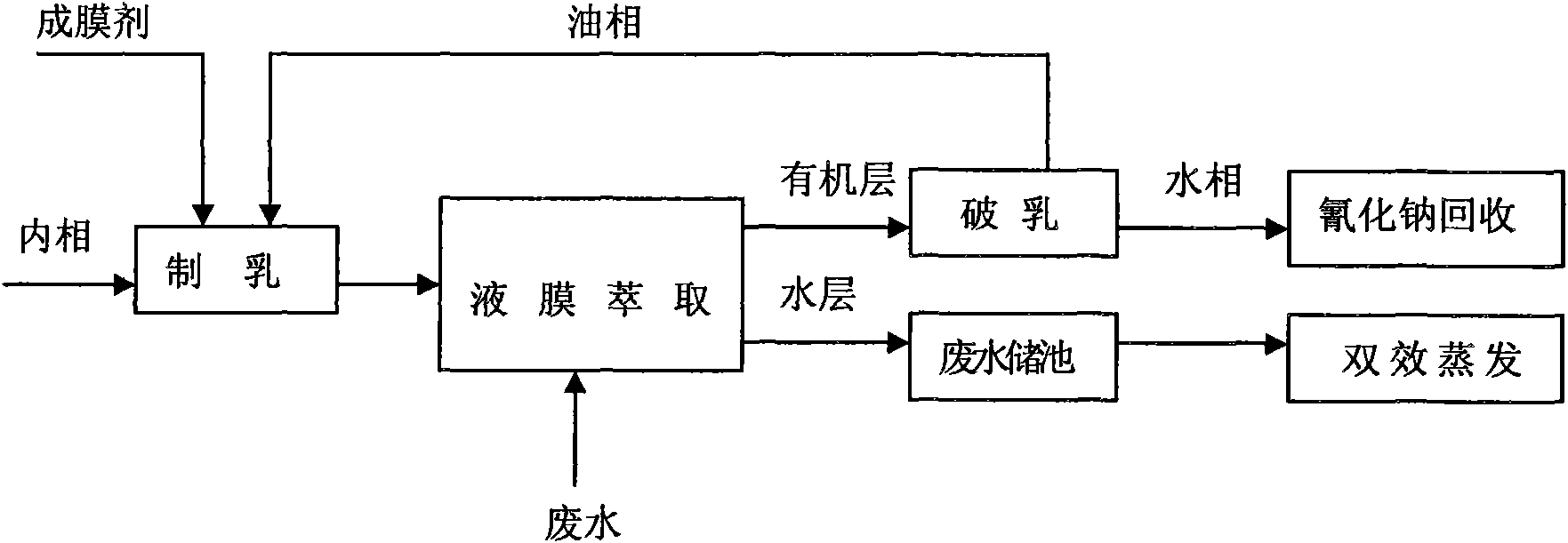

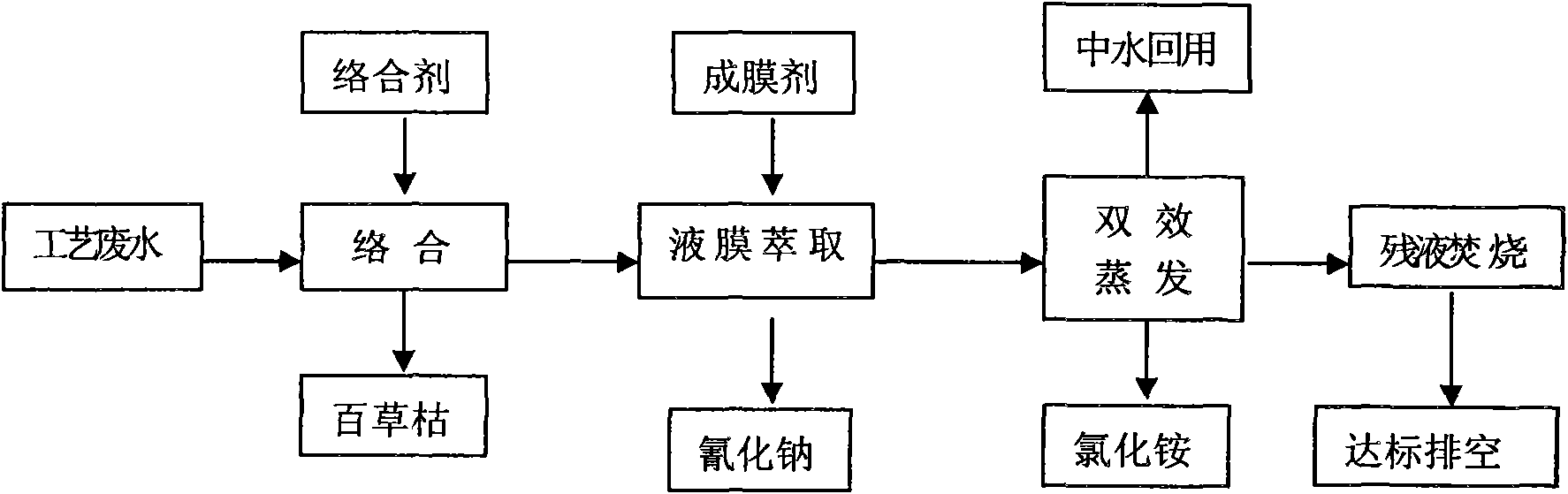

Method used

Image

Examples

Embodiment 1

[0026] The paraquat content of the untreated paraquat wastewater is 0.12wt%, and the wastewater is directly added to the reactor at 25°C, and complexing agent DSD acid of different weights is added, stirred, and after the complexing agent absorbs paraquat, the wastewater is discharged into The cyanide-containing wastewater treatment device carries out the recovery in step 2). After the complex is press-filtered, the filtrate is mainly paraquat mother liquor, which can be processed into 20% paraquat water solution and sold as a product. See Table 1 for the recovery rates of paraquat at different dosages of complexing agents.

[0027] Table 1

[0028] DSD Acid: Wastewater

Embodiment 2

[0030] Recovery of cyanide ions:

[0031] Use SPAN80, E644, ENJ3029, blue-113 respectively as surfactant, get surfactant, liquid paraffin and kerosene according to the ratio of volume fraction 5%, 12% and 83% and be made into organic phase, place in the milk maker, After stirring evenly, slowly add NaOH solution (0.25mol / L) equal to the volume of organic matter, and stir at high speed for 20 minutes to make a white water-in-oil emulsion. Take 250ml of water sample to be treated with cyanide ion, put it in a separator, adjust the pH to 5-7 with HCl, add 20ml of the water-in-oil emulsion prepared above, stir at 200-300r / min for 8min, let it stand for stratification, and the upper layer It is an organic phase, and the lower layer is an aqueous solution, which is separated by clarification. The organic phase was demulsified by a high-voltage electrostatic demulsifier for 5 minutes, and separated into an oil phase and an aqueous phase. The upper layer is the organic phase (which ...

Embodiment 3

[0036] Recovery of ammonia from wastewater:

[0037] The content of ammonium chloride in the wastewater treated through steps 1), 2) is 14.35wt%, and 500g of the wastewater is first added to the exhaust gas preheater and the first-effect condensed water preheater for preheating, and then enters the first-effect evaporator , be warming up to 115 ℃, underpressure distillation, pressure is kept on-0.06MPa, when the concentration of ammonium chloride in the waste water is about 28wt%, enter the vapor-liquid separation of the first-effect separation chamber, and the raffinate of the first-effect evaporator is transferred to Two-effect evaporator, keep the temperature at 90°C, distill under reduced pressure, the pressure is -0.075MPa, distill until the concentration of ammonium chloride in the waste liquid is about 33wt%, stop the distillation, transfer the waste liquid to the crystallization tank and cool to 25°C crystallization. The raffinate and ammonium chloride crystals are se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com