Composite electrode materials for high power lithium secondary battery and preparation method thereof

A lithium secondary battery and composite electrode technology, applied in battery electrodes, electrode manufacturing, active material electrodes, etc., can solve problems such as lack of innovation, and achieve the effects of improving high-power discharge capacity, cycle life, and specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

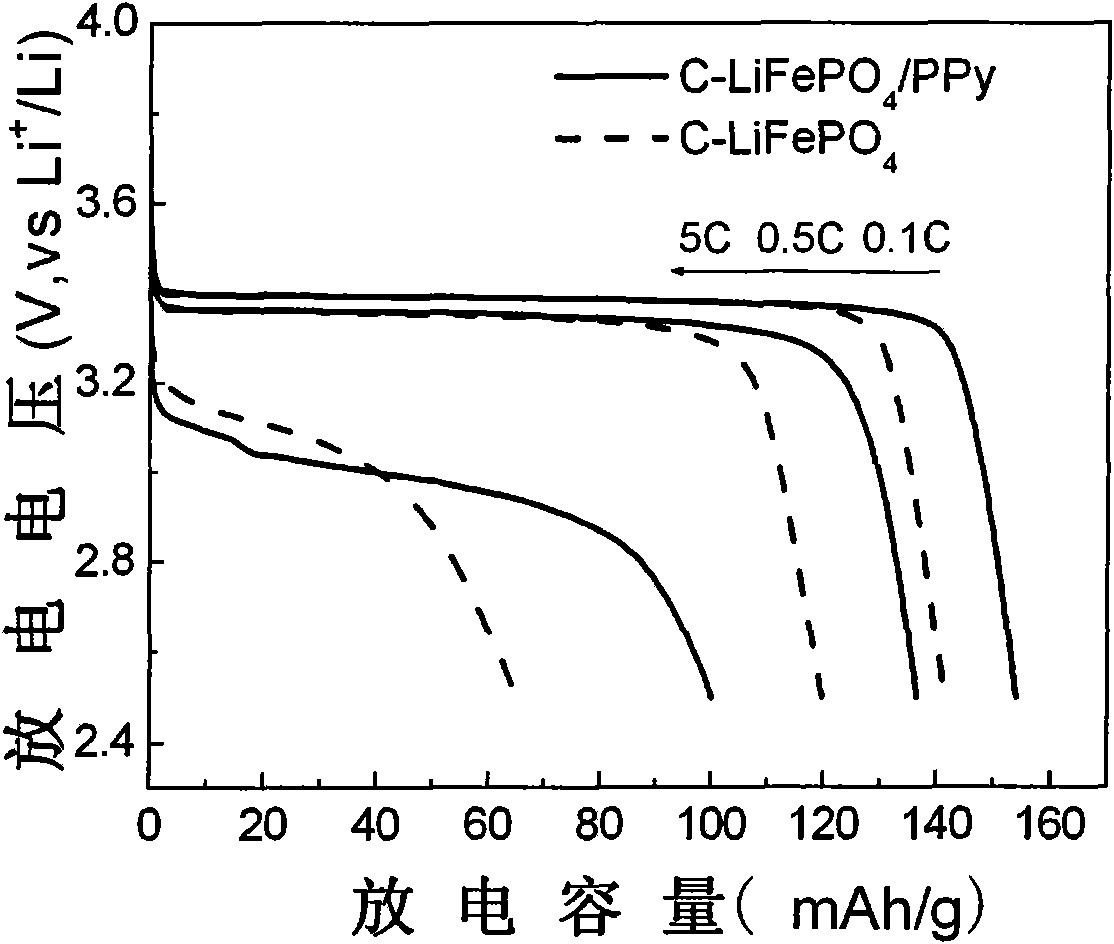

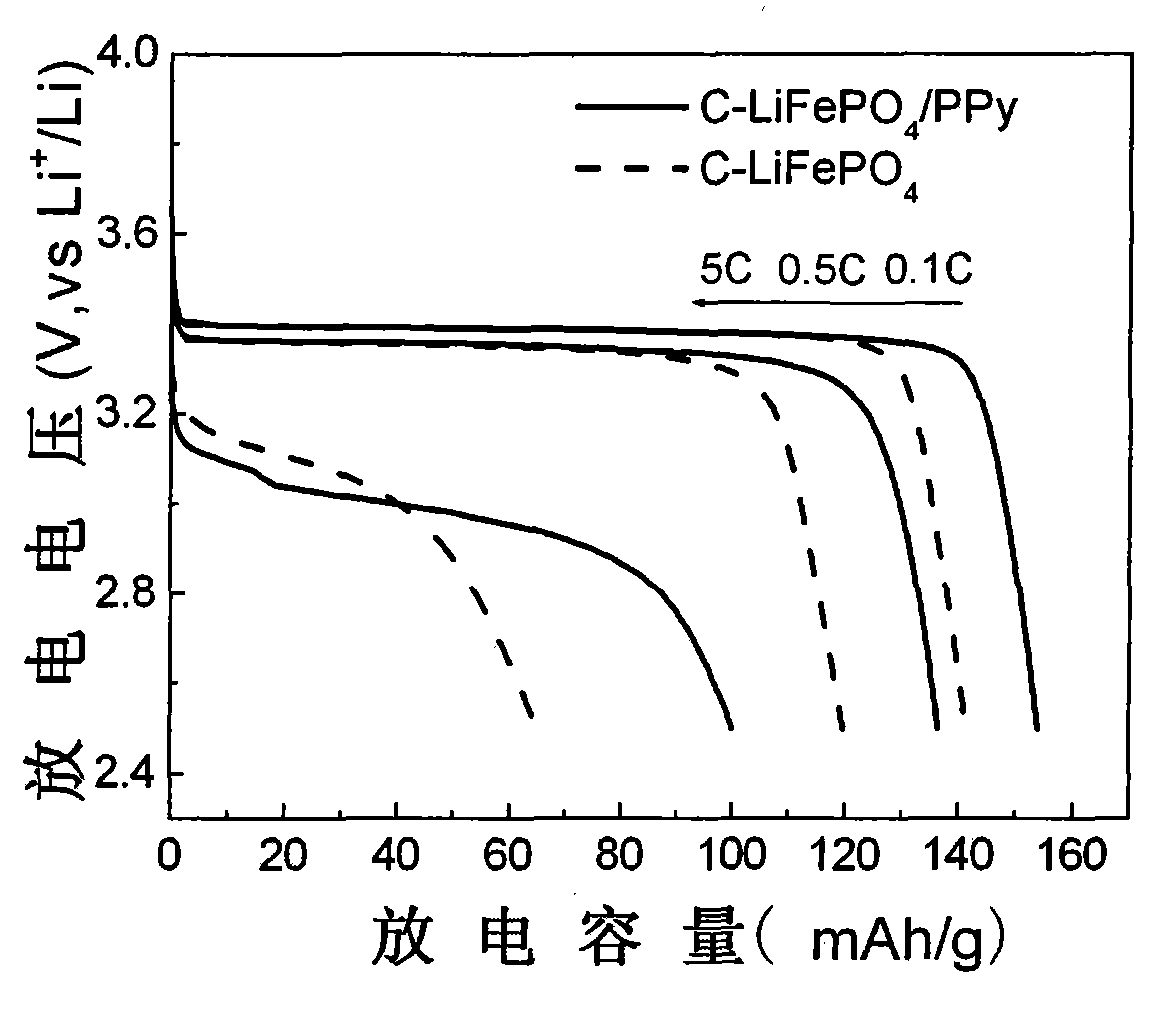

[0021] Embodiment 1 In situ electropolymerization method

[0022] First prepare 100ml 0.02mol / L pyrrole Py propionitrile solution, then add 0.5g carbon-coated lithium iron phosphate C-LiFePO 4 powder, and 0.1 g of supporting electrolyte LiClO 4 , ultrasonically disperse for half an hour to obtain a uniformly dispersed suspension, then place the working electrode and the counter electrode in the suspension, and perform cyclic voltaic in the potential range of 1.3V to 0.1V (relative to the Ag / AgCl reference electrode). An electrochemical polymerization, after 10 minutes of polymerization, a uniform layer of PPy-coated C-LiFePO was obtained on the working electrode 4 The composite film (C-LiFePO 4 / PPy), the mass fraction of PPy is 16% by differential thermal analysis. Directly use the composite membrane as the working electrode, the metal lithium sheet as the counter electrode, and the polypropylene microporous membrane as the diaphragm, and use 1mol / L LiPF 6 / EC-DMC (1:1) s...

Embodiment 2

[0023] Example 2 In situ electropolymerization method

[0024] First configure 100ml of 0.1mol / L aniline ANI in propionitrile solution, then add 1gLiCo 1 / 3 Ni 1 / 3 mn 1 / 3 o 2 powder and 0.2 g of supporting electrolyte LiClO4 , then add 0.05g of surfactant polyethylene oxide, magnetically stir for 1 hour to obtain a uniform suspension, then place the working electrode and counter electrode in the suspension, and apply 0.1mA / cm2 to the working electrode 2 The constant current electrochemical polymerization was carried out at a current density of 100%. After 30 minutes of polymerization, a uniform layer of polyaniline-coated LiCo was obtained on the working electrode. 1 / 3 Ni 1 / 3 mn 1 / 3 o 2 Composite film (LiCo 1 / 3 Ni 1 / 3 mn 1 / 3 o 2 / PANI), it is known that the massfraction of PANI is 35% by differential thermal analysis. Directly use the composite membrane as the working electrode, the metal lithium sheet as the counter electrode, and the polypropylene microporous membr...

Embodiment 3

[0025] Embodiment 3 in situ chemical polymerization method

[0026] Prepare 100ml of 0.01mol / l triphenylamine hydrochloric acid solution with pH=3~5, then add 1gLiMn 2 o 4 Powder and 0.05g of doping agent sodium toluenesulfonate, mechanically stirred to obtain a uniform suspension, at a temperature of 0 to 5 degrees, add 10ml of 0.01mol / L ammonium persulfate (oxidant) solution for oxidative polymerization , reacted for 5 hours under the condition of 0-5 degrees, filtered, washed and dried with deionized water and ethanol several times to obtain polytriphenylamine-coated LiMn 2 o 4 As for the composite electrode material, the mass fraction of polytriphenylamine in the composite material is 3% through differential thermal analysis. Mix the composite material, acetylene black AB, and polytetrafluoroethylene PTFE emulsion uniformly at a ratio of 95:2:3, roll it into a film with a thickness of about 100 μm, and then press it on the aluminum mesh current collector to make a worki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com