Method for preparing hydrophilic molecular imprinting microsphere by using ionic liquid as novel functional monomer by suspension method

A technology of molecularly imprinted microspheres and functional monomers, applied in chemical instruments and methods, and other chemical processes, can solve the problems of low imprinting efficiency, limited interaction types of related groups, and weak hydrophilicity, etc., to achieve selective High performance, strong rigidity, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

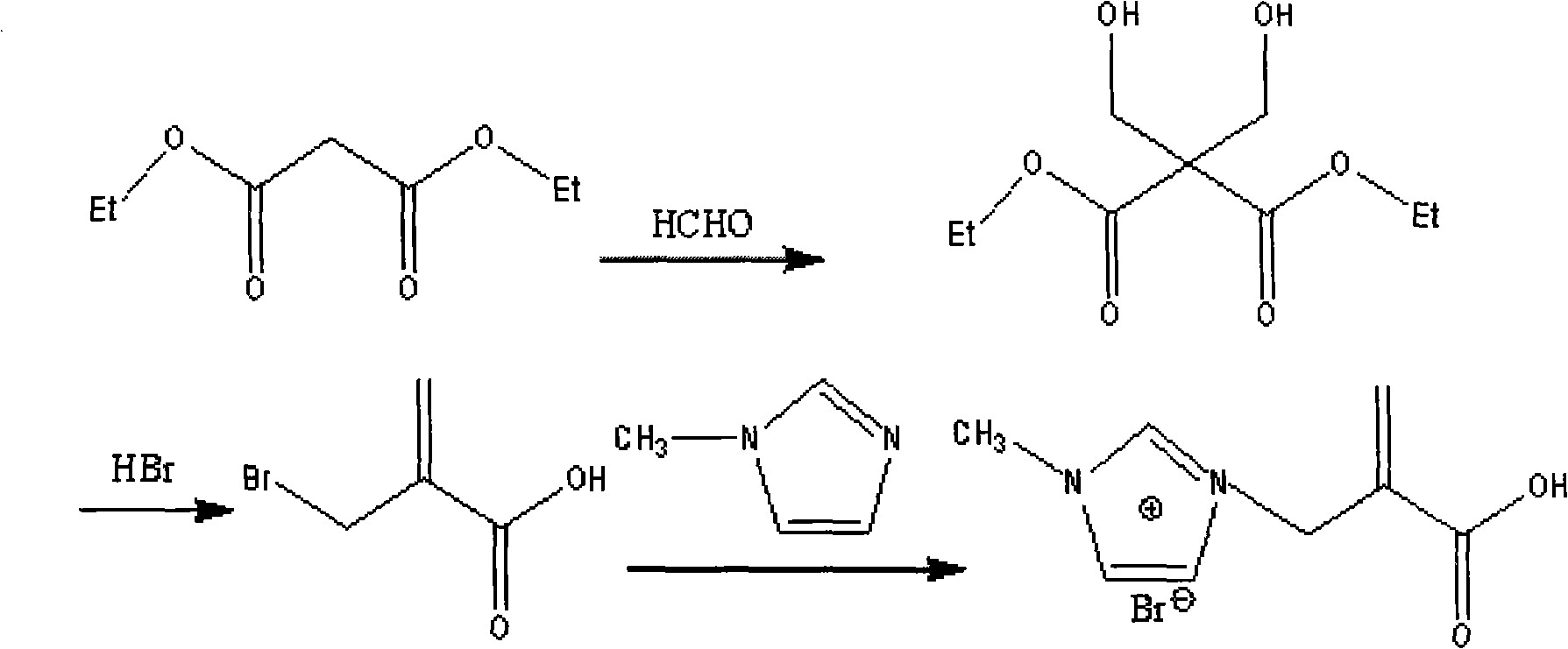

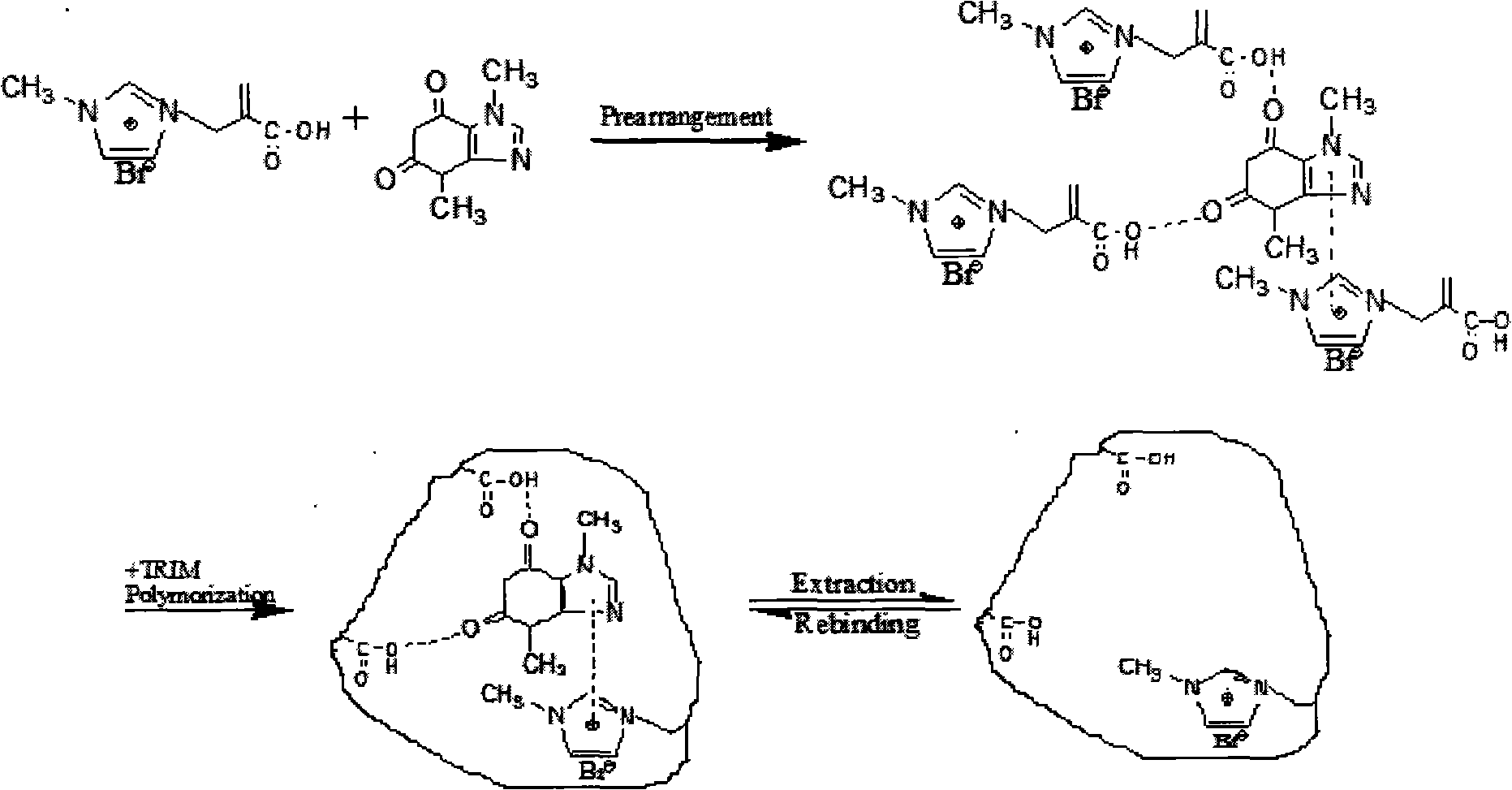

Method used

Image

Examples

Embodiment 1

[0029] Put 6.0000g of PVA124 and 150mL of water into a 250mL four-neck flask, stir to dissolve and heat to 85-90°C. Dissolve 0.6880 g of α-methacrylic acid functional monomer and theophylline in 20 mL of water, and add them into the four-neck bottle. Then 13.5200g TRIM, 0.2000g AIBN and 10mL of toluene were mixed and stirred, and when the AIBN was dissolved, they were added to the four-necked flask, and N 2 Seal it after 5 minutes, and stir at constant temperature (75°C) and constant speed (365rpm) for 8 hours to complete the reaction.

[0030] Elution process

[0031] The polymer obtained by the reaction was first washed twice with 100mL acetone and ethanol; (甲醇) :V (乙酸) = 9:1 solution elution, until the caffeine in the eluent can not detect the imprinted molecules in the high performance liquid chromatography, and then repeatedly washed with deionized water until neutral, and finally the eluted polymer was air-dried at room temperature Instant MIPs. When caffeine was u...

Embodiment 2

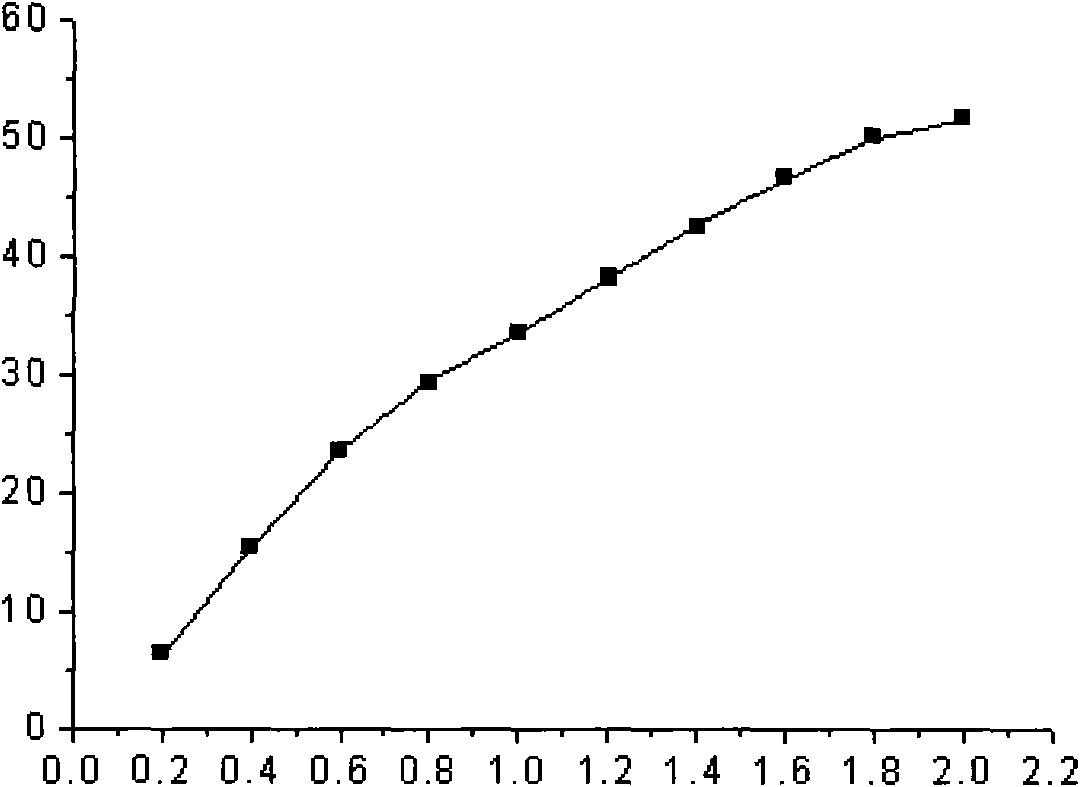

[0033] Put 6.0000g of PVA124 and 150mL of water into a 250mL four-neck flask, stir to dissolve and heat to 85-90°C. The synthesized 2.0000 ionic liquid functional monomer and 0.3883g of caffeine were dissolved in 20mL of water and added to the four-necked bottle. Then 13.5200g TRIM, 0.2000g AIBN and 10mL of toluene were mixed and stirred, and when the AIBN was dissolved, they were added to the four-necked flask, and N 2 Seal it after 5 minutes, and stir at constant temperature (75°C) and constant speed (365rpm) for 8 hours to complete the reaction. Such as figure 1 As shown, the abscissa represents the initial solubility of caffeine, and the ordinate represents the temperature, and the temperature is also rising with the increase of the caffeine solubility.

[0034] The elution process is the same as above

[0035] When theophylline was used as a competitive substrate, the separation factor of the obtained polymer in water environment was 1.91, and when cyromazine was used...

Embodiment 3

[0037] Put 6.0000g of PVA124 and 150mL of water into a 250mL four-neck flask, stir to dissolve and heat to 85-90°C. Dissolve 2.0000g of the synthesized new functional monomer and 0.3603g of theophylline in 20mL of water, and add them to the four-necked bottle. Then 13.5200g TRIM, 0.2000g AIBN and 10mL of toluene were mixed and stirred, and when the AIBN was dissolved, they were added to the four-necked flask, and N 2 Seal it after 5 minutes, and stir at constant temperature (75°C) and constant speed (365rpm) for 8 hours to complete the reaction.

[0038] The elution process is the same as above

[0039] When caffeine was used as a competitive substrate, the separation factor of the obtained polymer in aqueous environment was 1.41, and when cyromazine was used as a competitive substrate, the separation factor was 6.51. The microspheres of the obtained polymer were on average 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com