Plasticizing, oxidation resistance and thermal stabilization modifying agent of PVC material and preparation method thereof

A PVC material, anti-oxidation technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid esters, etc., can solve the problems of limited catalyst application, high toxicity of organic mercury, easy dehydration of hydroxyl groups into ethers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

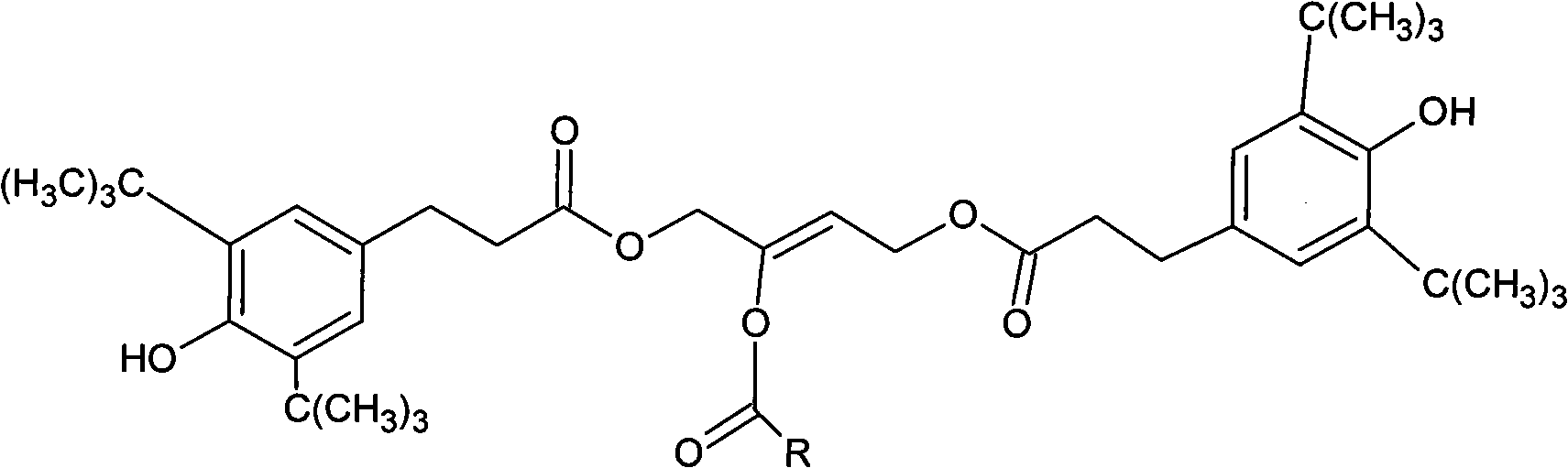

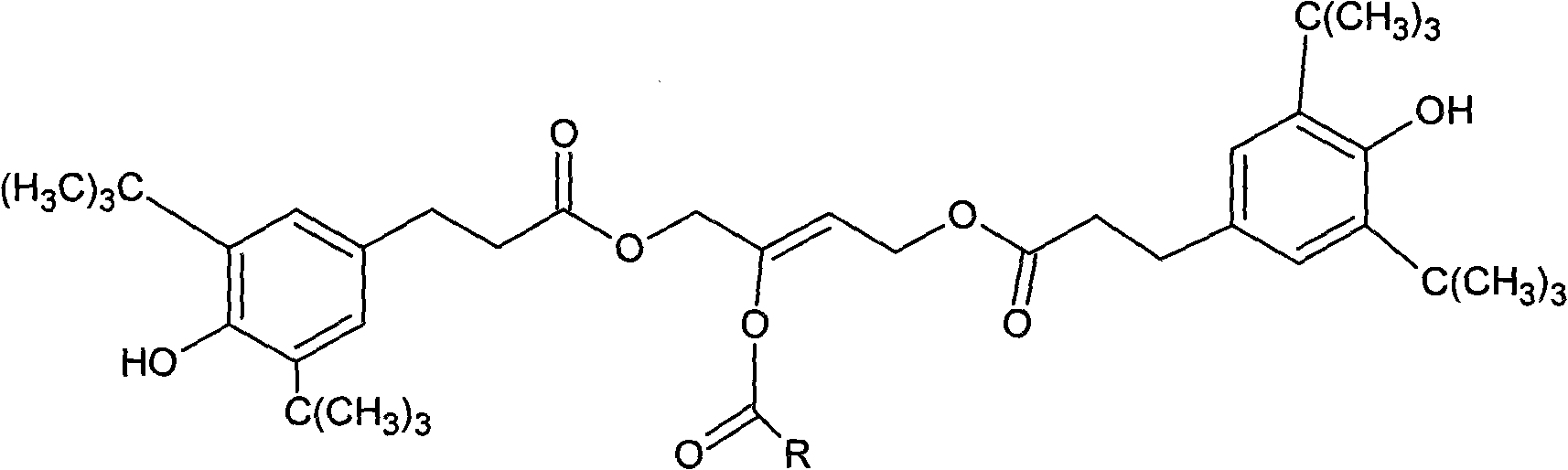

[0027] Preparation of 2-butyne-1,4-diol bis(3,5-di-tert-butyl-4-hydroxyphenylpropionate) ester

[0028] Install a 500mL round bottom flask on a magnetic stirring electric heating mantle, add 2-butyne-1,4-diol 17.2g (0.2mol), solvent 200mL, 3,5-di-tert-butyl-4-hydroxyphenylpropane Acetate methyl ester 117g (0.4mol), catalyzer (0.01mol), put on the fractionation column (built-in glass filler) that height is 60cm, install distillation head and straight condenser tube on the top of fractionation column, adjust the voltage, slowly heat and reflux for 1 Hour. Then slightly increase the voltage to control the temperature at the top of the fractionation column to not exceed 68°C. The generated methanol was gradually distilled off, and the reaction was stopped when the amount of methanol reached 20 mL. Pour out the reaction solution while hot. Cool and filter the resulting solid. Dry naturally, weigh, and calculate the crude yield. The crude product was recrystallized with an equa...

Embodiment 2

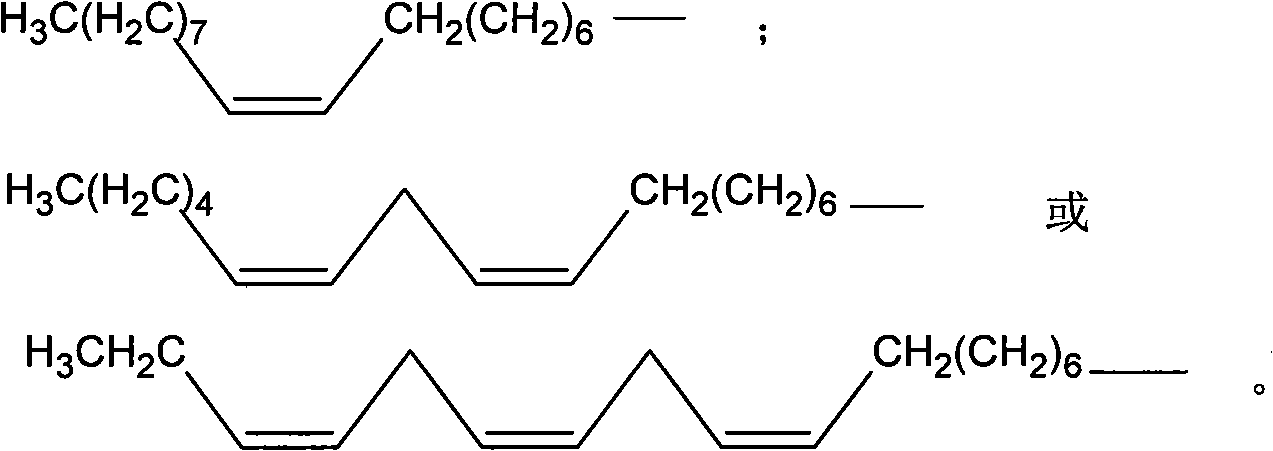

[0036] Preparation of 2-lauroyloxy-2-butene-1,4-diol bis(3,5-di-tert-butyl-4-hydroxyphenylpropionate) ester.

[0037] In a 500mL three-necked flask equipped with mechanical stirring, add 2-butyne-1,4-diol bis(3,5-di-tert-butyl-4-hydroxyphenylpropionic acid) ester 60.7 through crystallization purification in Example 1 g (0.1mol), lauric acid (n-dodecanoic acid) 20.0g (0.1mol), catalyst (0.002mol). Install a reflux condenser and a thermometer, heat up to a certain temperature and stir the reaction until the TLC detects that the raw material point disappears, cool to 80°C, add 200mL cyclohexane to reheat and dissolve, filter while it is hot, and the filtrate cools to precipitate white flaky crystals, the result Listed in Table 3. 2-lauroyloxy-2-butene-1,4-diol bis(3,5-di-tert-butyl-4-hydroxyphenylpropionate) ester, melting point: 104-106°C. 1 H NMR (500MHz, CDCl 3 ): δ6.95(4H, s), 5.56(2H, s), 5.26(1H, t, J=6.5Hz), 5.12(2H, d, J=6.5Hz), 5.00(2H, s), 2.96 -2.85 (4H, m), 2.65-2....

Embodiment 3

[0043] Preparation of 2-palmitoyloxy-2-butene-1,4-diol bis(3,5-di-tert-butyl-4-hydroxyphenylpropionate) ester

[0044] Add the 2-butyne-1,4-diol bis(3,5-di-tert-butyl-4-hydroxyphenylpropionic acid) ester through crystallization and purification in a 500mL three-necked flask equipped with mechanical stirring 60.7g (0.1mol), palmitic acid (hexadecanoic acid) 25.6g (0.1mol), cuprous acetate 0.245g (0.002mol). Install the upper reflux condenser and thermometer, raise the temperature to 135°C and stir for 11 hours until the raw material point disappears as detected by TLC, cool to 80°C and add 200mL cyclohexane to reheat to dissolve, filter while hot, the filtrate cools and precipitates white flaky crystals 80.3 g, yield: 93.0%, melting point: 97-99°C. 1 H NMR (500MHz, CDCl 3 ): δ6.98(4H, s), 5.52(2H, s), 5.24(1H, t, J=6.0Hz), 5.12(2H, d, J=6.0Hz), 5.01(2H, s), 2.95 -2.85 (4H, m), 2.65-2.48 (6H, m), 1.50 (2H, m), 1.35-1.20 (60H, m), 0.92 (3H, t, J=7.5Hz). Elemental analysis (C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com