Application of molybdenum carbide in preparing anode of microbial fuel cell

A technology of fuel cells and microorganisms, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problems that microbial fuel cells have not yet reflected the application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

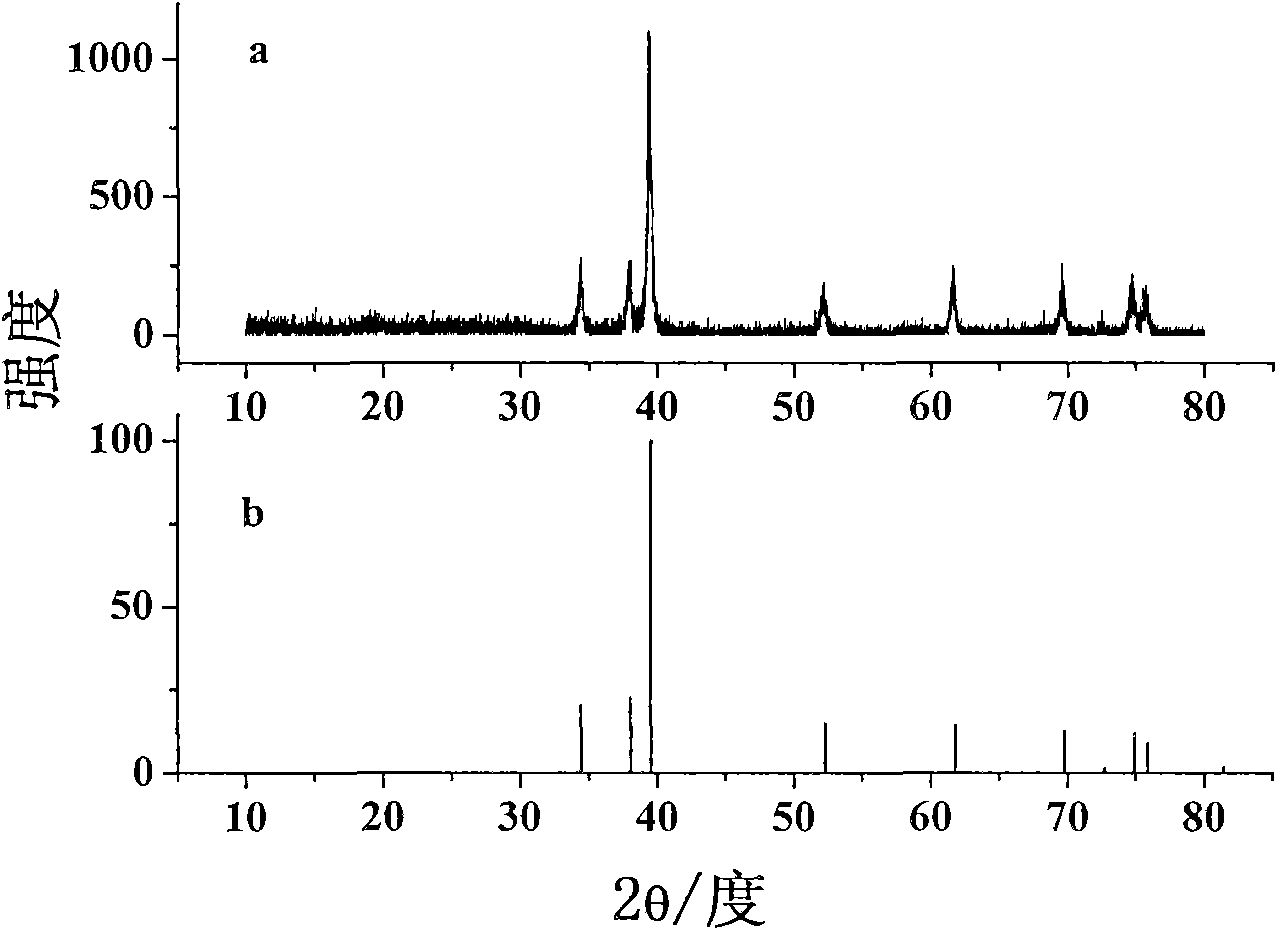

[0037] Step 1: Catalyst Preparation

[0038] 1. Put MoO at room temperature 3 Suspended in 5 ml of 30% aqueous H 2 o 2 After 50 hours, add 5ml of distilled water, pour off the supernatant, and add 1ml of 30% H to the undissolved residue. 2 o 2 , heated to about 60°C to make it dissolve, and then lowered the two solutions to mix and heat to about 80°C, the color changed from yellow to orange, and the solvent evaporated at room temperature, and crystallized molybdenum hydroperoxide was precipitated. This orange-red solvent is used as the starting solvent for the carbide precursor.

[0039] 2. Molybdenum peroxide and sucrose precursors are prepared by using 1.02g of sucrose solution in the above original solvent, heated to about 60°C to form a blue solvent, and evaporated to dryness at 120°C to form blue precursor fragments.

[0040] 3. The fragments were placed in a graphite boat and annealed in an alumina tube furnace at a temperature of 900°C, under the protection of Ar, an...

Embodiment 2

[0051] Step 1: Catalyst Preparation

[0052] The steps are as example 1

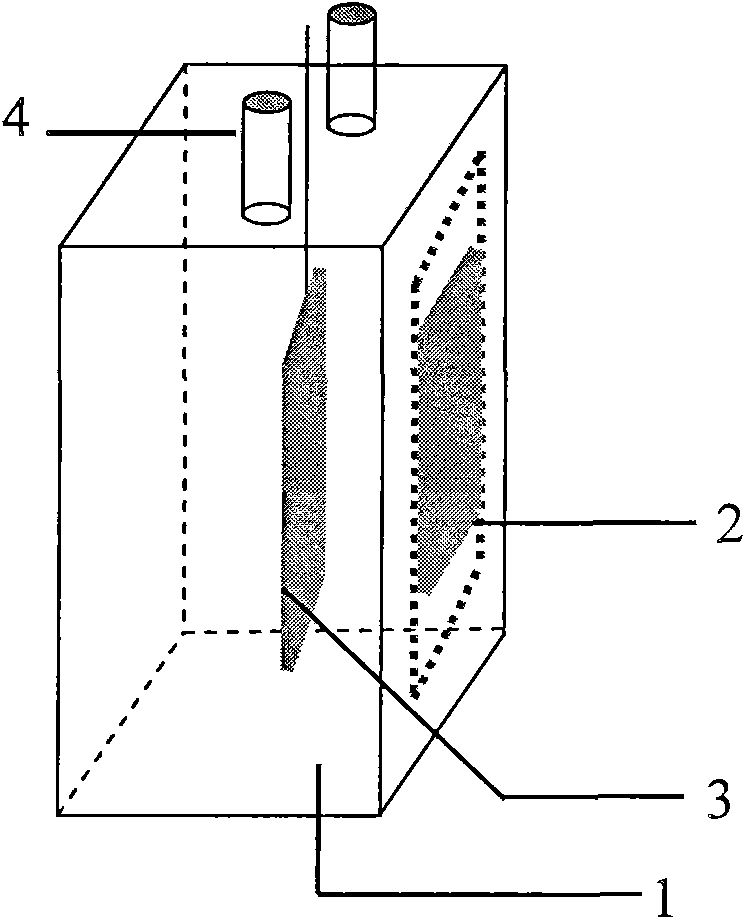

[0053] Step 2: Preparation of the base electrode

[0054] Add 108 mg of molybdenum carbide powder to 1 mL of binder (30% to 60% polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF)) and mix well, stir to form a paste and disperse it ultrasonically; Spread on carbon felt, then dry at 100°C to get 6mg / cm 2 Molybdenum carbide catalytic electrodes.

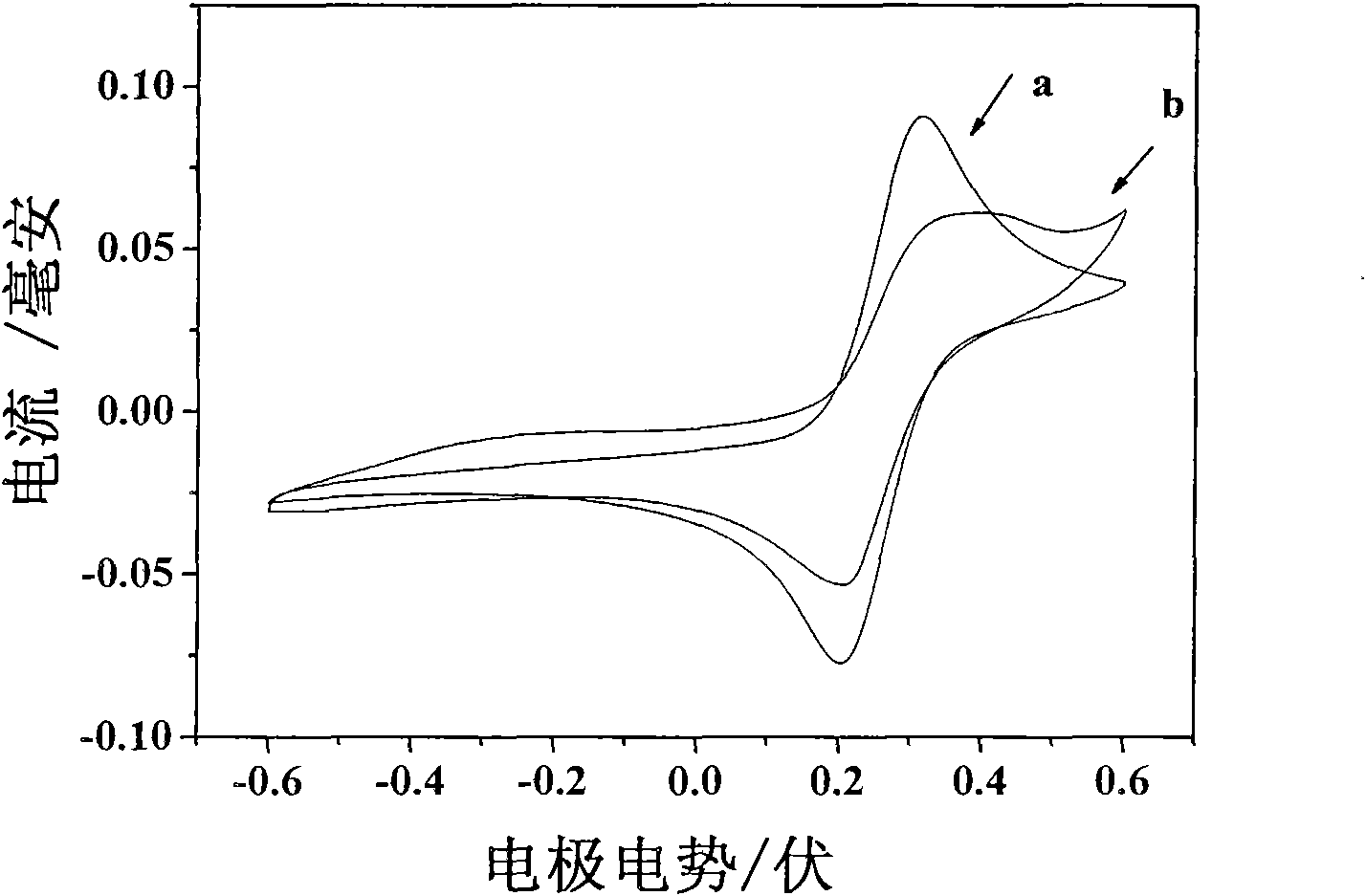

[0055] Step 3: Electrochemical Testing

[0056] With Pt rod ( =1mm) is the counter electrode, Ag / AgCl is the reference electrode, 5.0mM Fe(CN)63- / 4-and 0.1M KCl is the electrolyte, molybdenum carbide is added to the ethanol solution of 0.5wt% Nafion to disperse uniformly by ultrasonic, adjust Turn into a blue slurry, use a pipette gun to pipette 1 μL of the solution and drop it on the platinum electrode, and dry it in the air to form a 3mg / cm 2 The molybdenum carbide research electrode is used to investigate the resistance of molybdenum carbide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com