A kind of preparation method of high-functionality aqueous uv resin composition of 100% solid content

A resin composition, high-functionality technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of unsatisfactory crosslinking density, adhesion and mechanical properties, low solid content of waterborne UV coatings, scope of application and application To solve problems such as small fields, to achieve excellent light curing rate, increase the content of unsaturated bonds, avoid solvent volatilization and waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

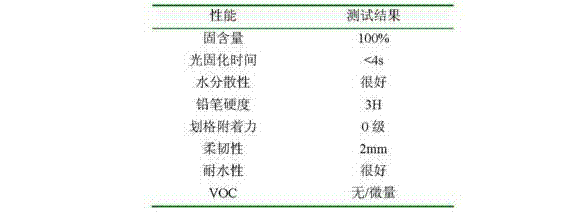

Embodiment 1

[0025] Embodiment 1: In the there-necked flask that stirrer, condenser tube, nitrogen passage are housed, add 10.7g dimethylolpropionic acid, 60.9g toluene diisocyanate, 120g polycaprolactone diol, a small amount of dibutyltin dilaurate and acetone, under the protection of a nitrogen atmosphere, the temperature was raised to 40°C with constant stirring, and the concentration of -NCO in the system was determined by di-n-butylamine titration; after reaching the expected value, 89.4g of pentaerythritol triacrylate was added to the system, and an appropriate amount of acetone was added Adjust the viscosity and react at 60°C for 3-6 hours to obtain a high-functionality water-based UV resin prepolymer A, lower the temperature to 30°C, add triethylamine to the prepolymer to neutralize the acetone solution of the prepolymer, And add 20g of hydroxyethyl methacrylate, 12g of Darocur 1173, 30g of hexanediol diacrylate, 20g of tripropylene glycol diacrylate, etc., stir for 1 to 2 hours, an...

Embodiment 2

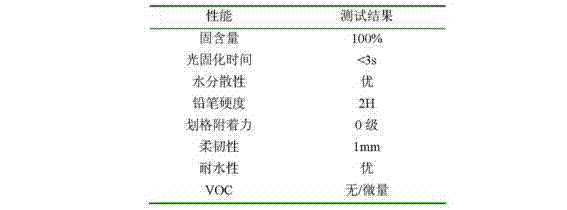

[0030] In a three-necked flask equipped with a stirrer, a condenser, and a nitrogen passage, add 8.04g of dimethylolpropionic acid, 53.28g of isophorone diisocyanate, 120g of polytetrahydrofuran ether glycol, a small amount of dibutyltin dilaurate and acetone , under the protection of a nitrogen atmosphere, the temperature was raised to 60° C. with constant stirring and reacted for 2 to 4 hours. Next, 35.76 g of pentaerythritol triacrylate was added to the system, and an appropriate amount of acetone was added to adjust the viscosity, and reacted at 70° C. for 6 to 8 hours to obtain a high-functionality water-based UV resin prepolymer. Cool down to 30°C, add 6g of triethylamine to the prepolymer for neutralization, add 40g of hydroxyethyl acrylate, 12g of Darocur 1173, a small amount of hexanediol diacrylate, tripropylene glycol diacrylate, etc., and stir for 1 After ~2h, the acetone was distilled off under reduced pressure to obtain a high-functionality water-based UV resin c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com