Low-platinum high active core-shell structure catalyst and preparation method thereof

A technology of catalyst and shell structure, applied in the field of low-platinum high-activity core-shell structure catalyst and its preparation, can solve the problems of expensive platinum and achieve the effects of solving cost and performance, easy control of reaction conditions, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

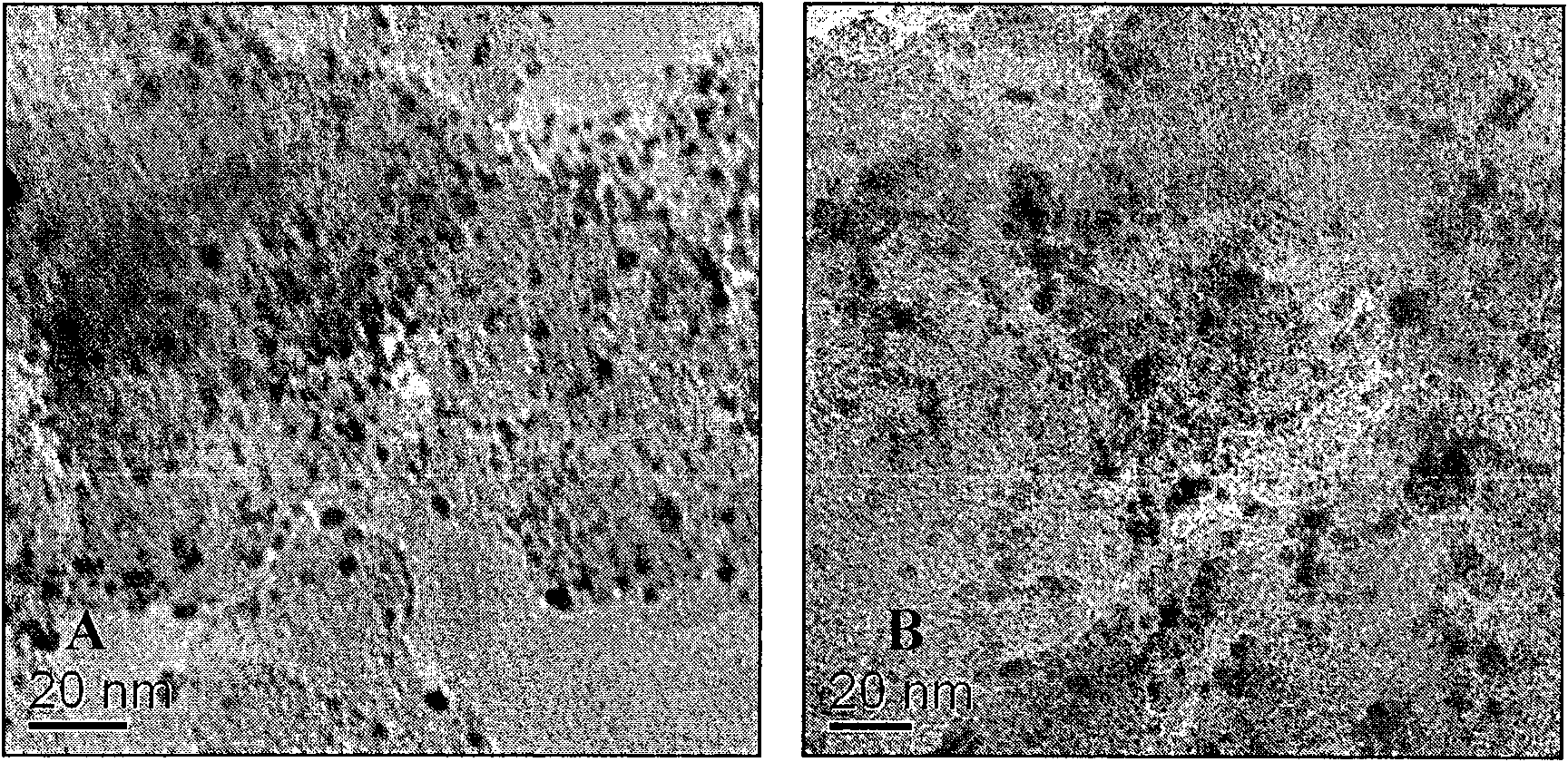

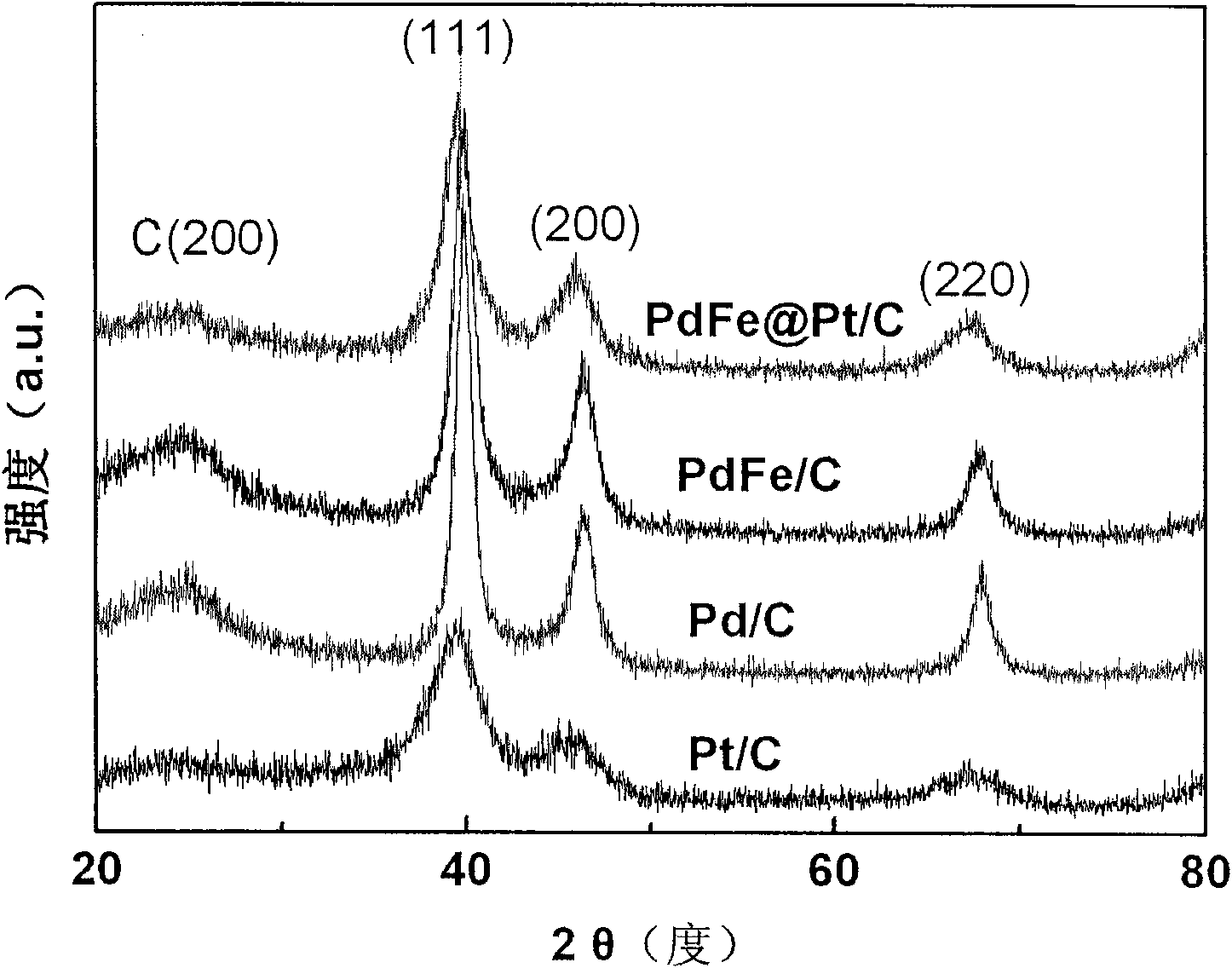

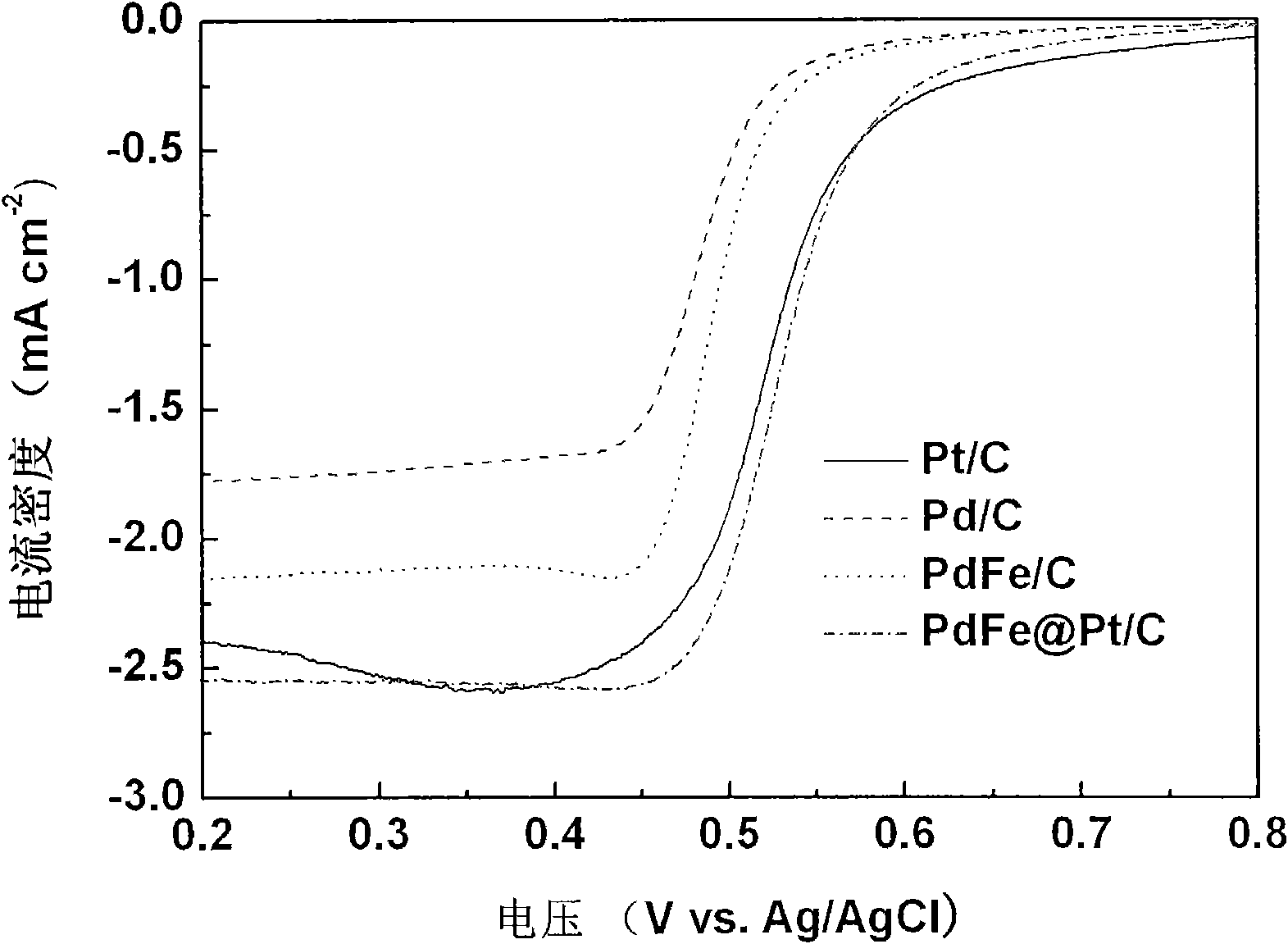

[0024] Embodiment 1: Preparation of Pd@Pt / C catalyst

[0025] Add 42.9 mg of palladium chloride into a 50 ml round-bottomed flask, add 25 ml of ethylene glycol, stir with a magnet, and sonicate for more than 0.5 hours to completely dissolve it. Add 193.8 mg of sodium citrate, stir until completely dissolved, adjust the pH of the solution to 9 with 5% KOH / EG solution; add 102.8 mg of sodium formate, 100 mg of carbon powder, stir for 0.5 hours, and ultrasonically for 0.5 hours; the obtained solution is transferred to high pressure Put it in a reaction kettle in an oven, and react at 160°C for 8 hours; the resultant is suction-filtered, washed with water three times until no chloride ions are detected in the solution, and vacuum-dried at 70°C to constant weight to obtain a catalyst precursor.

[0026] Weigh 17.0 mg of chloroplatinic acid, add to a round bottom flask, and add 20 ml of ethylene glycol (ethylene glycol is a solvent and also a reducing agent), and adjust the pH value...

Embodiment 2

[0028] Embodiment 2: Preparation of PdFe@Pt / C catalyst

[0029]Add 19.2mg of palladium chloride and 106.0mg of ferric chloride into a 50ml round-bottomed flask with 25ml of ethylene glycol, stir with a magnet, and ultrasonically dissolve them all for more than 0.5 hours; add 294.3mg of sodium citrate, and stir until completely dissolve. Use 5% KOH / EG solution to adjust the pH of the solution to 10, add 156.2 mg of sodium formate and 100 mg of carbon nanotubes, stir for 0.5 hours, and sonicate for 0.5 hours.

[0030] The above solution was transferred to an autoclave, placed in an oven, and reacted at 160° C. for 8 hours. The resultant was suction-filtered, washed with water three times until no chloride ions were detected in the solution, and vacuum-dried at 70°C to constant weight to obtain a catalyst precursor.

[0031] Weigh 9.4mg of chloroplatinic acid, add to a round bottom flask, and add 20ml of ethylene glycol, 5% KOH / EG solution to adjust the pH of the solution to be...

Embodiment 3

[0033] Embodiment 3: Preparation of PdCo@Pt / C catalyst

[0034] Add 36.3 mg of palladium chloride and 32.3 mg of cobalt chloride into a 50 ml round-bottomed flask, then add 25 ml of ethylene glycol, stir with a magnet, and ultrasonically dissolve them all for more than 0.5 hours; add 232.0 mg of sodium citrate, and stir until completely dissolved. Use 5% KOH / EG solution to adjust the pH value of the solution to 9, add 123.12 mg of sodium formate, add 100 mg of carbon powder, stir for 0.5 hours, and sonicate for 0.5 hours; React for 8 hours. The resultant was suction-filtered, washed with water three times until no chloride ions were detected in the solution, and vacuum-dried at 70°C to constant weight to obtain a catalyst precursor.

[0035] Weigh 8.9 mg of chloroplatinic acid, add to a round bottom flask, and add 20 ml of ethylene glycol, adjust the pH of the solution to be alkaline to 10 with 5% KOH / EG solution, add 1 ml of formaldehyde, and add 50 mg of the catalyst precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com