Active magnetic bearing using bias magnetic flux commonly in radial direction and in axial direction and control method thereof

An active magnetic bearing, axial technology, applied in the direction of shafts and bearings, bearings, mechanical equipment, etc., can solve the failure to make progress in the overall system's compact axial structure and the improvement of the critical speed of the rotor, and the long axial length of the mechanical structure. , large size of the power amplifier, etc., to achieve the effect of compact structure, easy control, and reducing the size of the power amplifier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

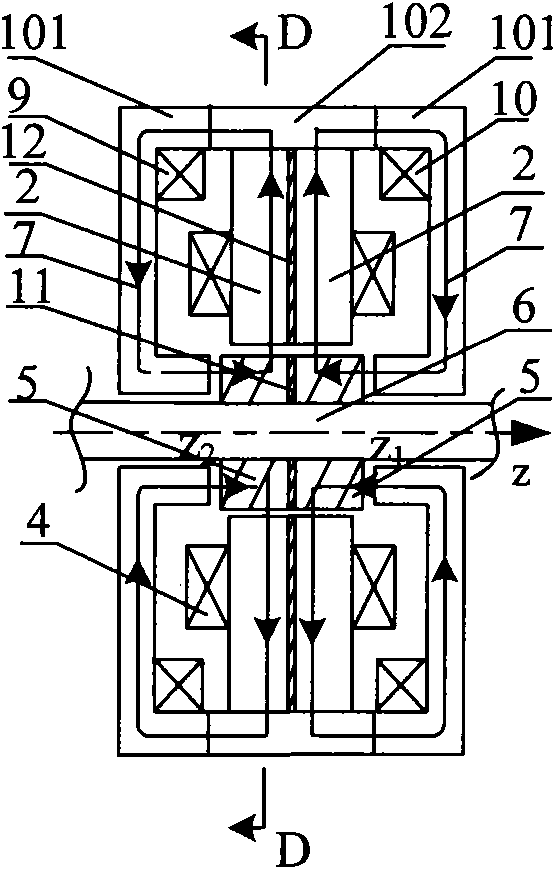

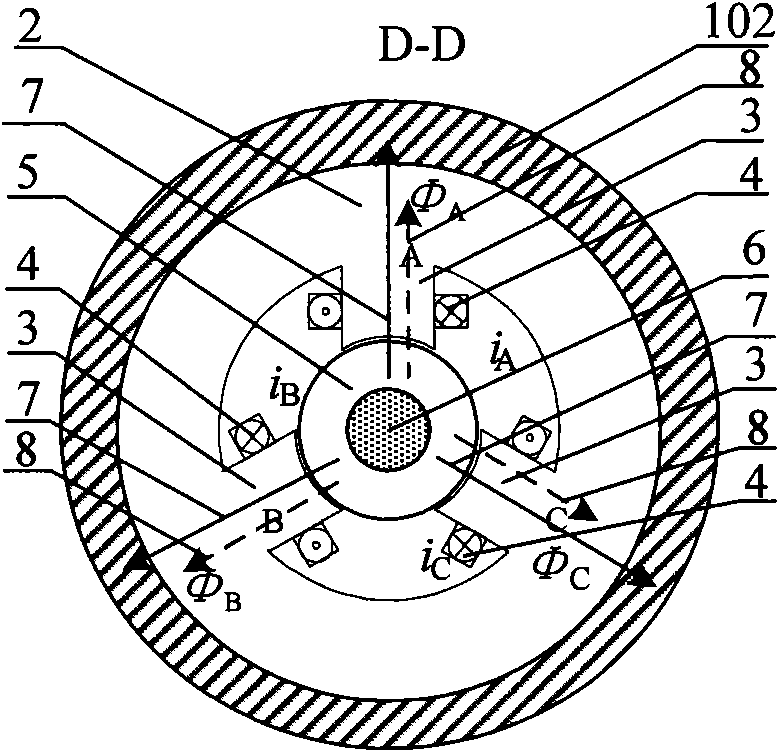

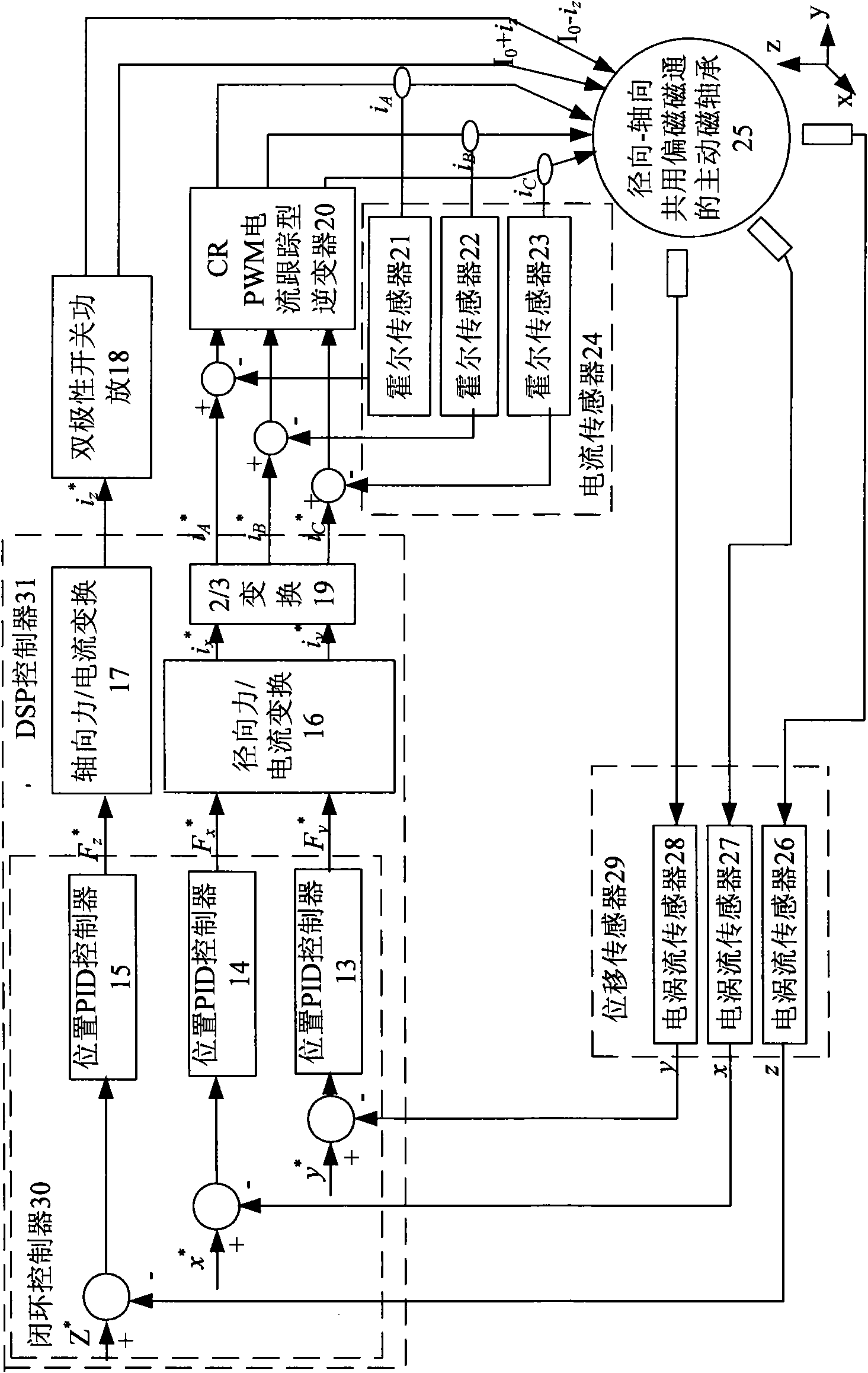

[0021] The present invention firstly designs the structure and magnetic circuit of the active magnetic bearing with radial-axial shared bias flux, and deduces the active magnetic bearing with radial-axial shared bias magnetic flux according to the magnetic field assumption conditions and the equivalent principle of magnetic circuit. The mathematical model of the bearing, and then design the structural parameters and electrical performance parameters of the magnetic bearing according to the mathematical model and combined with the predetermined technical indicators. Based on these structural parameters, use the finite element analysis software Maxwell 3D to further optimize the design of the magnetic bearing structural parameters, and verify the correctness of the structural design principles and magnetic flux distribution. Finally, according to the mathematical model and various actual parameters, the controller is designed and a double closed-loop control system is constructed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com