Method of producing electrochemical active material

A technology of active materials and manufacturing methods, applied in chemical instruments and methods, inorganic chemistry, circuits, etc., can solve the problems of unstable sintering control, over-burning, power consumption, etc., and achieve good electrochemical stability and excellent electrochemical performance. , the effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

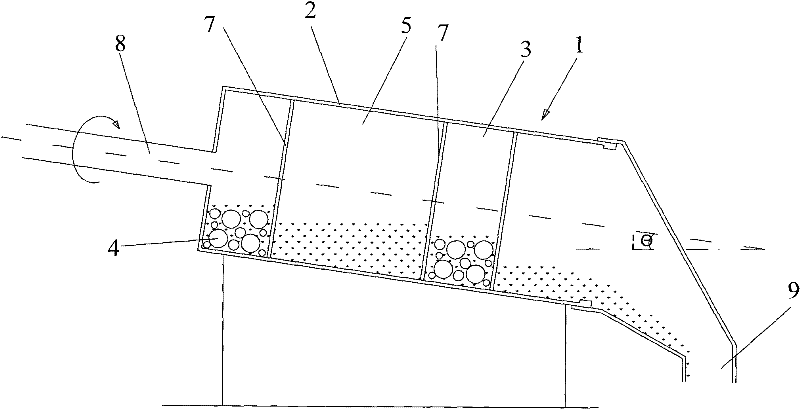

[0022] Embodiment: A kind of manufacturing method of electrochemically active material, comprises adopting ball milling rotary furnace 1 to carry out material pulverization, mixing, synthesis and circulation, the furnace tube 2 of described ball milling rotary furnace 1 is provided with at least one with ball milling medium 4 Ball mill heating interval 3.

[0023] The material is mainly a mixture of ferrous salt, lithium salt and phosphate, the molar ratio of the ferrous salt, lithium salt and phosphate is 1:1:1, and the electrochemically active material is lithium ferrous phosphate.

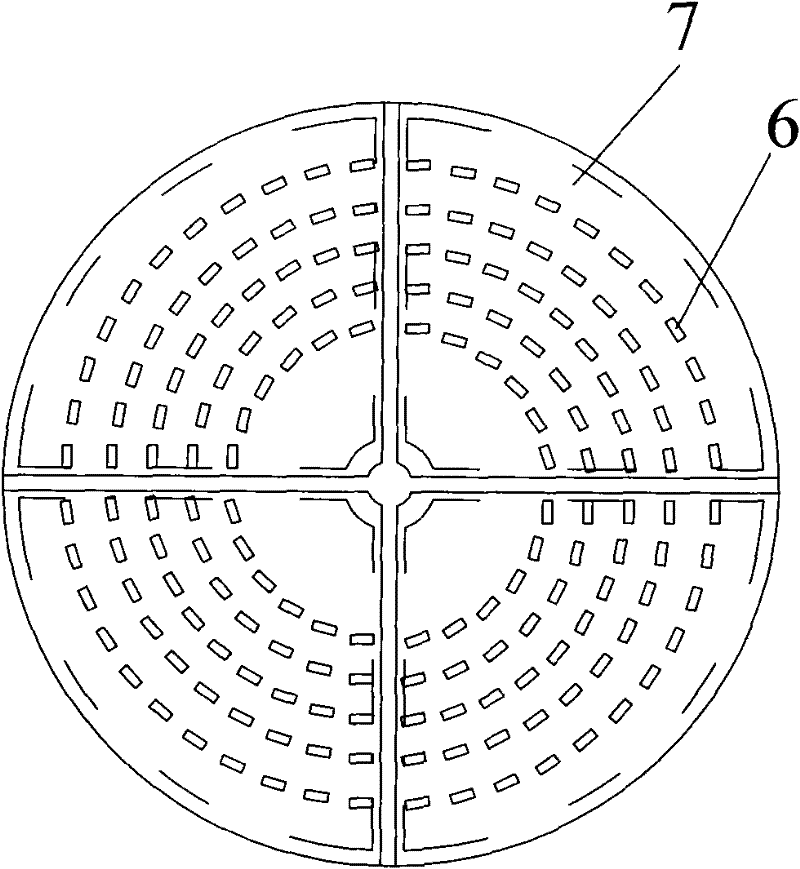

[0024] The structure of ball milling rotary furnace 1 is as follows: figure 1 and figure 2 As shown, it includes a feed system 8, a discharge system 9, a furnace tube 2, a conventional heating zone 5 and two ball mill heating zones 3 distributed inside the furnace tube 2. The heating temperature and time of each zone are individually controlled by PID. There are baffles 7 on both sides of ea...

specific Embodiment 1

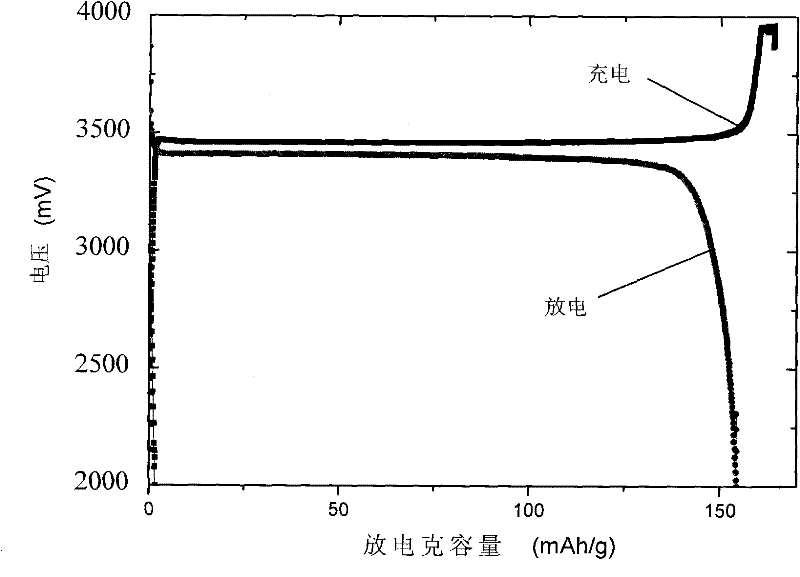

[0025] After fully mixing ferrous phosphate and lithium carbonate or lithium hydroxide in a molar ratio of 1:1, the materials are continuously put into the ball milling rotary furnace under the condition of nitrogen protection. For 4 hours, when the temperature in the high-temperature zone is controlled at 400-800 degrees, keep warm for 1-4 hours at a rotation speed of 1 revolution / minute, and then cool at room temperature. The product lithium ferrous phosphate is obtained through milling, testing and packaging. In the electrochemical test process, conductive carbon black and binder are added to make pole pieces, and metal lithium sheets are used as counter electrodes for electrochemical tests. The tap density of the material prepared in this embodiment is greater than 1.3g / cm 3 , the electrochemical discharge gram capacity of the electrode material is greater than 150mAh / g, such as image 3 shown.

specific Embodiment 2

[0026] Thoroughly mix iron oxide, ammonium dihydrogen phosphate and lithium carbonate or lithium hydroxide in a molar ratio of 1:1:1, then add conductive carbon black and mix, and then continuously enter the ball milling rotary furnace under the condition of nitrogen protection, the low-temperature synthesis process In the middle, the temperature is controlled at 200-400 degrees, and the temperature is kept for 1-4 hours. When the temperature in the high-temperature zone is controlled at 400-800 degrees, the temperature is kept for 1-4 hours, and the rotation speed is 1 revolution / minute, and then cooled at room temperature. The product lithium ferrous phosphate is obtained through milling, testing and packaging. In the process of electrochemical test, conductive agent and binder are added to make pole piece, and metal lithium piece is used as the test counter electrode. The tap density of the material prepared in this embodiment is greater than 1.2g / cm 3 , The electrochemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com