A preparation method of high-dielectric and low-loss insulating copper-calcium titanate ceramics

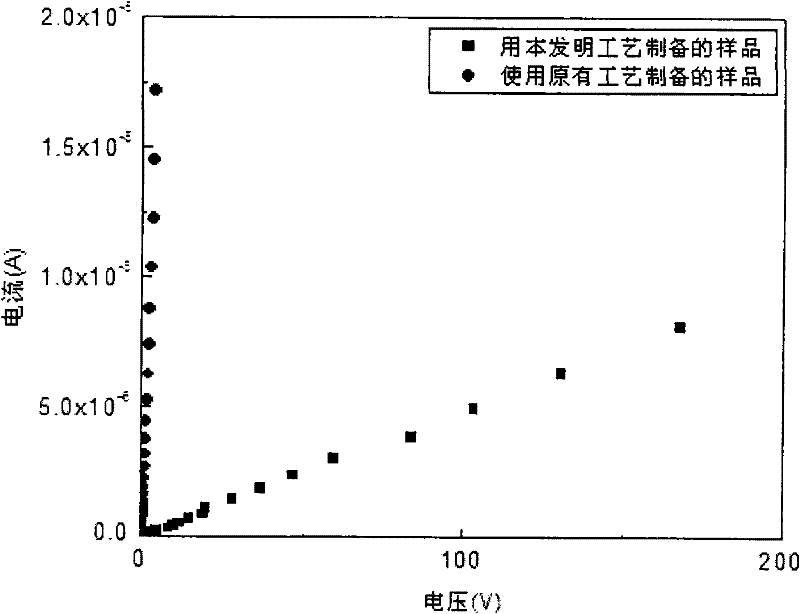

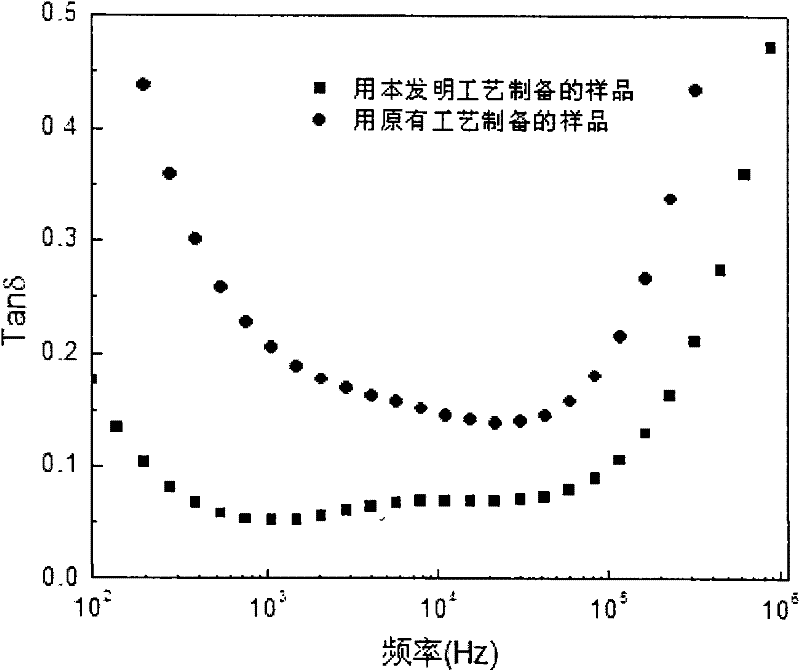

A technology of calcium copper titanate and low loss is applied in the field of preparation of high dielectric and low loss insulating copper calcium titanate ceramics, which can solve the problems of complicated process, increased cost, etc., to reduce energy consumption, reduce leakage current and dielectric properties. The effect of electrical losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

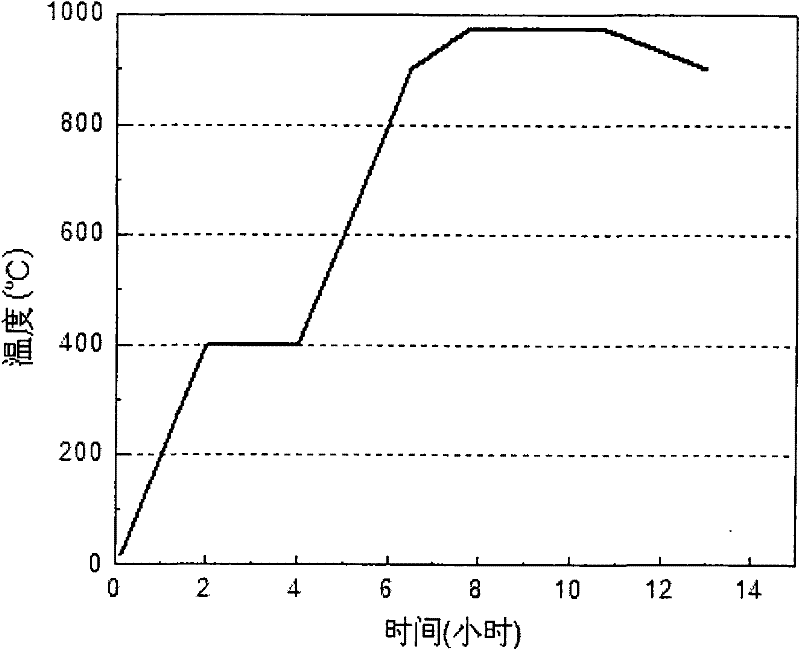

[0022] The preparation method of the high-dielectric and low-loss insulating copper calcium titanate ceramics proposed by the present invention comprises the following steps:

[0023] (1) Preparation and mixing of raw materials:

[0024] Calcium copper titanate ceramics using CaCO 3 or CaO, CuO and TiO 2 is the initial raw material, wherein the mass ratio of each substance is: CaCO 3 :CuO:TiO 2 =1:(2.27-2.50):(3.03-3.35) or CaO:CuO:TiO 2 =1:(4.05-4.48):(5.42-5.99);

[0025] The above raw materials are mixed according to the above mass ratio for 2-24 hours and then dry-milled, or mixed and wet-milled for 2-24 hours, and dried;

[0026] (2) Calcination and grinding: If the raw material is CaO, this step can also be omitted,

[0027] Pre-burn the above-mentioned mixed and ground materials at 800°C to 950°C for 2-24 hours, cool with the furnace, crush the hard blocks after pre-burning and grind for more than 2-24 hours, or after wet grinding for 2-24 hours, dry and sieve; ...

Embodiment 1

[0035] (1) Preparation and mixing of raw materials:

[0036] The CCTO material uses CaO, CuO, TiO 2 As the initial raw material, the mass ratio of each raw material is CaO:CuO:TiO 2 =1:4.26:5.71.

[0037] The raw materials were dry-milled in a ball mill jar for 24 hours.

[0038] (2) Calcination and grinding:

[0039] The dried material was placed in a high-temperature electric furnace, and pre-fired at 900 degrees Celsius for 2 hours. Cool in the furnace.

[0040] The powder agglomerates after pre-firing. Crush the hard block after pre-burning and place it in a ball mill jar, and grind for 24 hours with alcohol as the grinding medium. The ground slurry is placed in a drying oven for drying, and passed through a 200-mesh sieve after drying.

[0041] (3) Molding:

[0042] Using tablet molding process. Hand granulation was performed using 3% PVA (polyvinyl alcohol) aqueous solution as a binder. Using a hydraulic press and a cylindrical mold with a diameter of 11.5 mm, ...

Embodiment 2

[0051] (1) Preparation and mixing of raw materials:

[0052] The CCTO material uses CaCO 3 , CuO, TiO 2 As the initial raw material, the proportioning is carried out according to the formation of pure phase CCTO. The mass ratio of each raw material is CaCO 3 :CuO:TiO 2 =1:2.385:3.193.

[0053] The raw materials were placed in a ball mill jar and mixed with alcohol as the grinding medium for 12 hours. The ball-milled slurry is placed in a drying oven for drying.

[0054] (2) Calcination and grinding:

[0055] The dried material was placed in a high-temperature electric furnace, and pre-fired at 900 degrees Celsius for 4 hours. Cool in the furnace.

[0056]The powder agglomerates after pre-firing. Crush the hard block after pre-burning and place it in a ball mill jar, and grind for 12 hours with alcohol as the grinding medium. The ground slurry is placed in a drying oven for drying, and passed through a 200-mesh sieve after drying.

[0057] (3) Molding:

[0058] Usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com