Method for pre-treating difficultly-degradable wastewater by catalyzed iron inner electrolysis fluidized bed

A fluidized bed and internal electrolysis technology, which is applied in anaerobic digestion treatment, chemical instruments and methods, sustainable biological treatment, etc. problems such as operating costs, to achieve the effect of improving the biodegradability of wastewater, simplifying the installation and replacement process, and widening the pH range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

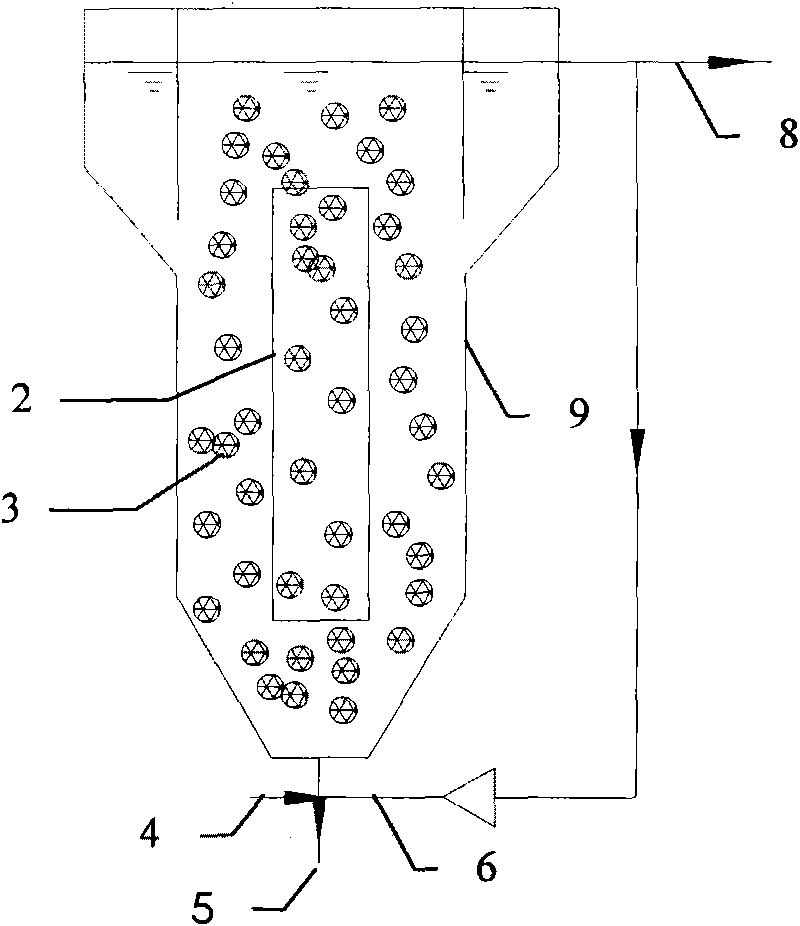

[0021] like figure 1 As shown, the wastewater from a certain fine chemical industry enters through the water inlet 4, and the return port 6 is adjusted to make the rising flow rate 3m / h, the diameter of the electrolytic filler in the suspended catalytic iron used is 25mm, and the iron-copper mass ratio is 10:1. The addition rate was 40%, and the reaction time in the packing zone was 2.0 h. Under this operating condition, the removal rate of COD, chroma, TP and the improvement of BOD / COD in the effluent of the fluidized bed are equal and greater than the effect of traditional catalytic iron internal electrolysis, but there is no decrease in treatment efficiency after continuous operation for 3 months. There is also no clogging problem, while the traditional catalytic iron internal electrolysis system needs to adopt a mechanical stirring method every 15d or so to ensure the stable operation effect.

Embodiment 2

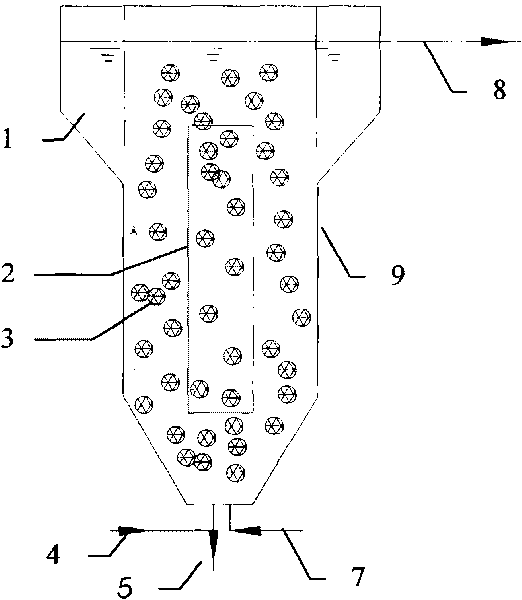

[0023] like figure 2 As shown, the comprehensive wastewater of a chemical park enters the fluidized bed system through the water inlet 4, and the air inlet 7 is controlled so that the dissolved oxygen concentration in the system is about 0.3 mg / L. Suspended catalytic iron electrolytic packing with a diameter of 25 mm and a mass ratio of iron to copper of 20:1 was used as the carrier in the fluidized bed, the dosage rate was 20%, and the reaction time in the packing area was 1.0 h. At the same time, hydrolysis acidification sludge is added to realize the coupling of catalytic iron internal electrolysis and hydrolysis acidification. Under the dual action of gas and water, the carrier and sludge in the system are in a fluidized state, and the COD, TP removal rate and BOD / COD change values of the final effluent are equal and greater than the traditional hydraulic retention time and the electrolysis reaction time in the catalytic iron. Advection catalytic iron / hydrolysis acidif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com