Degradation controlled tissue engineering comea fibrous scaffold and preparation method thereof

A fibrous scaffold and tissue engineering technology, which is applied in the field of degradable and controllable tissue engineered corneal fibrous scaffold and its preparation, can solve the problems of low mechanical strength and poor stability, and achieve low cost, simple preparation process, good biological activity and biophase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In a water bath at 37°C, 7 mg of gelatin was dissolved in 10 mL of a mixed solvent of 9.9 g of hexafluoroisopropanol and 0.1 g of N,N-dimethylformamide, and then 3 mg of polylactic acid PLLA was dissolved in the above gelatin solution to prepare The spinning liquid is obtained, and the tissue engineering corneal fiber scaffold is prepared through the electrospinning forming equipment. The working voltage of the electrospinning forming equipment is 18KV; 2cm parallel plate electrodes. The obtained scaffold was vacuum-dried at 40° C. for 3 days to obtain a tissue engineered corneal fiber scaffold with controllable degradation. After performance test: light transmittance 97.83%, wet tensile strength 2.19MPa, elongation at break 956.2%, water content 154.1%, contact angle 76.5°.

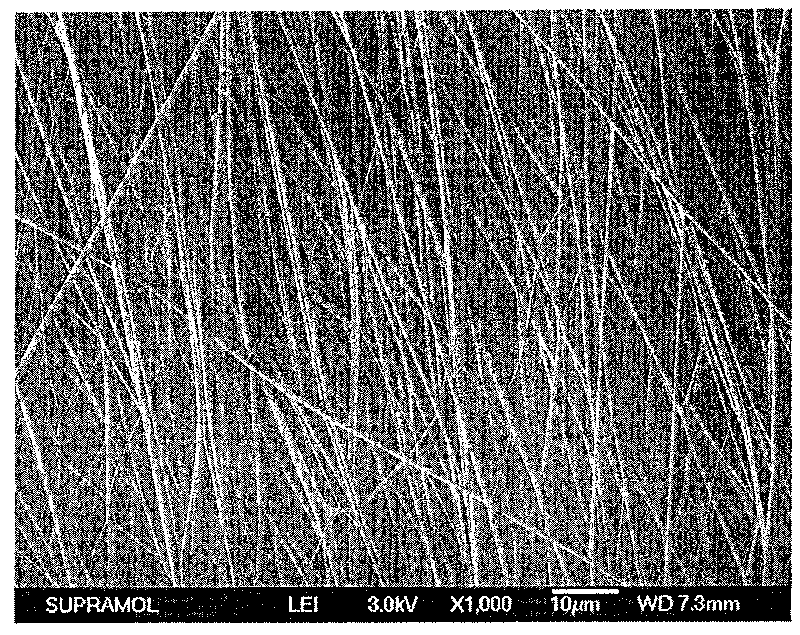

[0028] figure 1 It is the scanning electron micrograph of the degradable tissue engineering corneal fiber scaffold prepared by the present embodiment; from figure 1 It can be seen that the degr...

Embodiment 2

[0030] In a water bath at 32°C, dissolve 9 mg of gelatin in 10 mL of a mixed solvent of 9.8 g of hexafluoroisopropanol and 0.2 g of N, N-dimethylformamide, and then dissolve 1 mg of polylactic acid PLLA in the above gelatin solution to obtain Spinning liquid, through electrospinning forming equipment, prepares tissue engineering corneal fiber scaffold, the operating voltage of electrospinning forming equipment is 15KV; the receiving plate distance is 12cm, the sampling rate is 1.5mL / h, and the receiving device is 20cm in diameter Round foil. The obtained scaffold was vacuum-dried at 37° C. for 2 days to obtain a tissue engineered corneal fiber scaffold with controllable degradation. After performance test: the light transmittance is 97.26%, the wet tensile strength is 1.99MPa, the elongation at break is 816.6%, the water content is 95.09.%, and the contact angle is 109.21°.

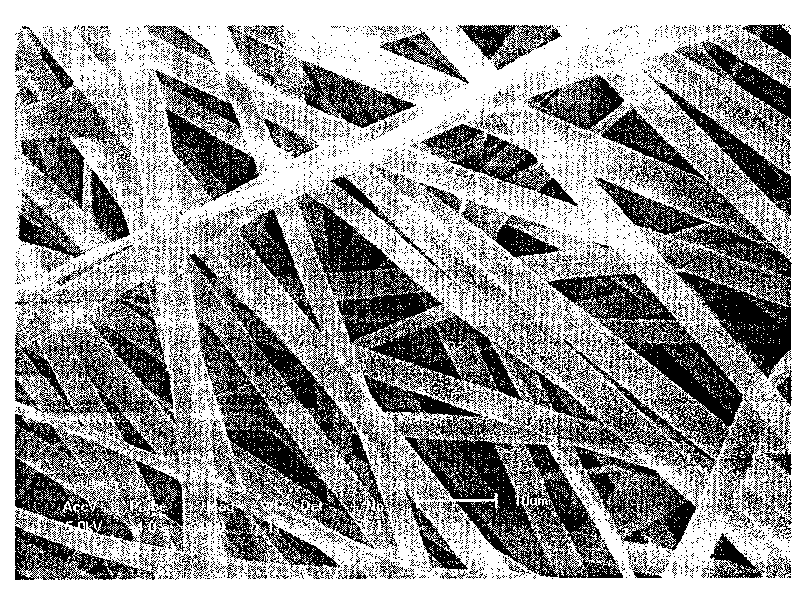

[0031] figure 2 It is the scanning electron micrograph of the degradable tissue engineering corneal...

Embodiment 3

[0033] In a water bath at 30°C, dissolve 8 mg of gelatin in 10 mL of a mixed solvent of 9.8 g of hexafluoroisopropanol and 0.2 g of N, N-dimethylformamide, and then dissolve 2 mg of polylactic acid PLA in the above gelatin solution to obtain Spinning liquid, through electrospinning forming equipment, prepare tissue engineering corneal fiber scaffold, the working voltage of electrospinning forming equipment is 20KV; the receiving plate distance is 15cm, the sampling rate is 2.0mL / h, and the receiving device is 18cm in diameter Round foil. The obtained scaffold was vacuum-dried at 30° C. for 4 days to obtain a tissue engineered corneal fiber scaffold with controllable degradation. After performance test: the light transmittance is 90.22%, the wet tensile strength is 4.72MPa, the elongation at break is 505.4%, the moisture content is 100.42.%, and the contact angle is 104.1°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com