Method for removing organic pollutants from water by drinking water enhanced treatment

A technology for the enhanced treatment of organic pollutants, applied in chemical instruments and methods, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of slow reaction speed, decreased performance of surface modified substances, and oxidation ability of simple oxidants Insufficient and other problems, to maintain the adsorption capacity, to make up for the loss of metal oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1. The source water of a surface water body has a turbidity of 2.6 NTU and a TOC of 6.2 mg / L after coagulation and sedimentation. Add a mixed solution of sodium hypochlorite and ferric chloride to the water, so that the concentration of sodium hypochlorite in the water is 4.5mg / L, and the concentration of ferric chloride is 0.3mg / L. The reaction time before filtration is 30s, and the residence time of the filter layer hollow bed is 10min. Aluminum, manganese oxide composite modified quartz sand filter material for filtration. The average turbidity of the filtered water is 0.5NTU, and the TOC is 2.5mg / L. The results of online color mass detection showed that the types of trace organic pollutants were reduced by 33%, and the total amount was removed by 65%. The same water quality is filtered through quartz sand, the average turbidity of the filtered water is 1.7NTU, the TOC is 4.9mg / L, the types of trace organic pollutants are not reduced, and the total amount is...

Embodiment 2

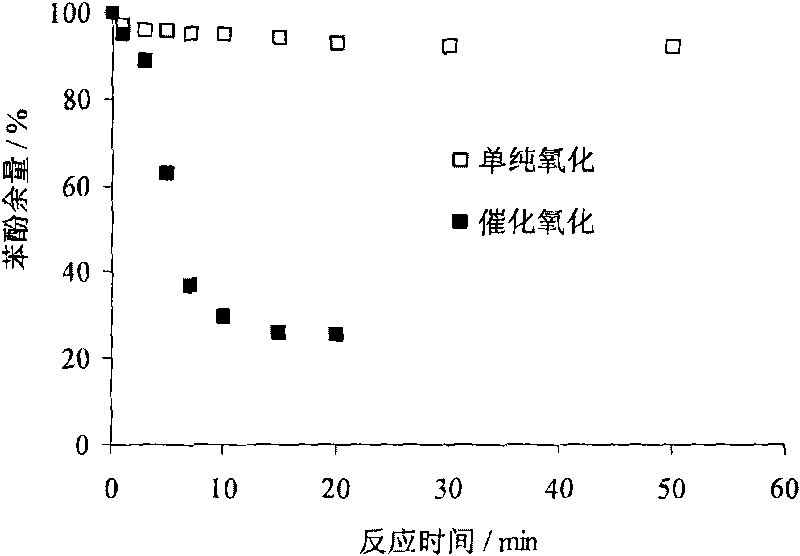

[0025]Example 2. A groundwater source has low content of natural organic matter but is polluted by phenol, and the content of phenol in the water is about 0.3 mg / L. Potassium permanganate is added at a concentration of 3 mg / L during the treatment process. After the addition, it enters the filter layer for filtration. The residence time of the hollow bed in the filter layer is 6 minutes. Iron oxide modified ceramsite is used as the filter material of the filter bed, and the effluent phenol The content can be kept below 0.1mg / L. Through the catalysis of the modified filter material, the phenol oxidation rate and oxidation speed are obviously improved. From figure 1 It can be seen that when the residence time of the hollow bed in the filter layer is 6 minutes, the removal rate of phenol is 70%, while the direct reaction between potassium permanganate and phenol, the removal rate of phenol is only less than 3%, and the removal efficiency is increased by more than 20 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com