Method for synthesizing nano titanium dioxide through microwaves

A nano-titanium dioxide and microwave synthesis technology is applied in the nano field to achieve the effects of excellent performance, excellent sensitivity and excellent photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Use titanium sulfate as the titanium source and deionized water as the reaction medium to prepare a 0.05mol / L titanium sulfate solution. Take 50ml of the above solution and place it in a polytetrafluoroethylene microwave reactor at 0.1Mpa, 110°C Under the condition of reaction for 30min, cooled to room temperature to obtain a milky white suspension;

[0032] (2) ultrafiltration, get the solid and wash to no SO 4 2- , and finally washed with absolute ethanol for 1 to 2 times, and vacuum-dried at 75° C. for 1 hour to obtain nano-sized titanium dioxide particles.

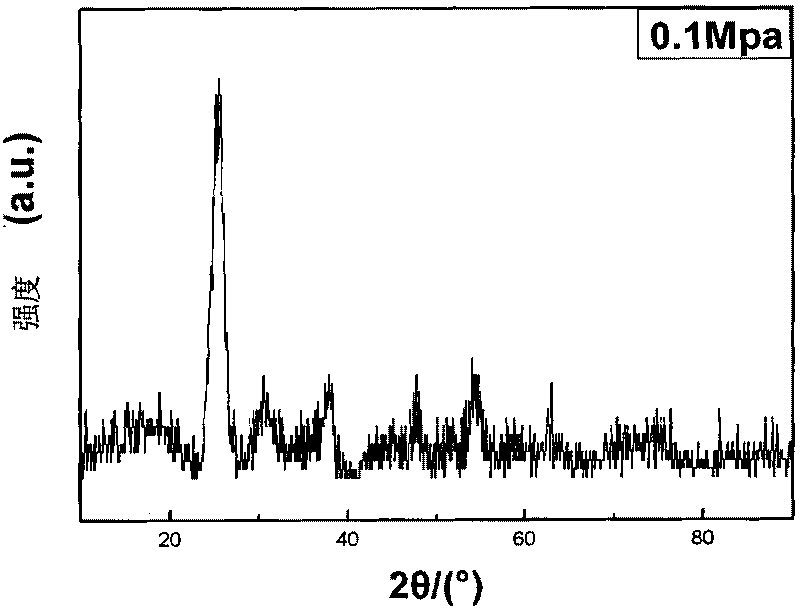

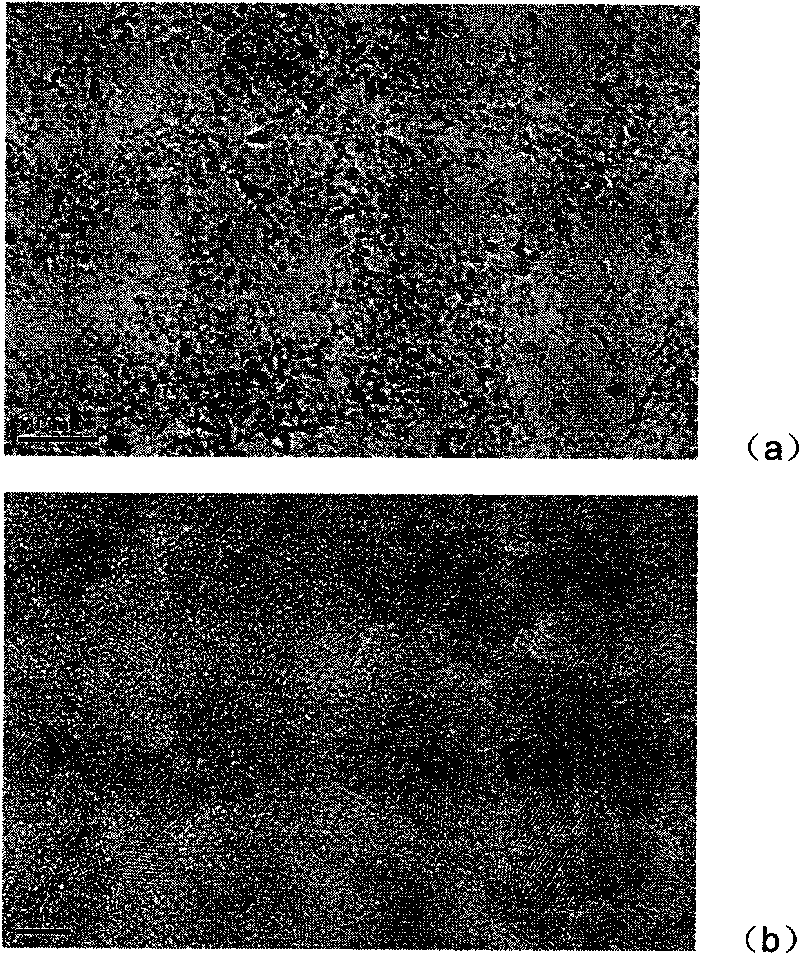

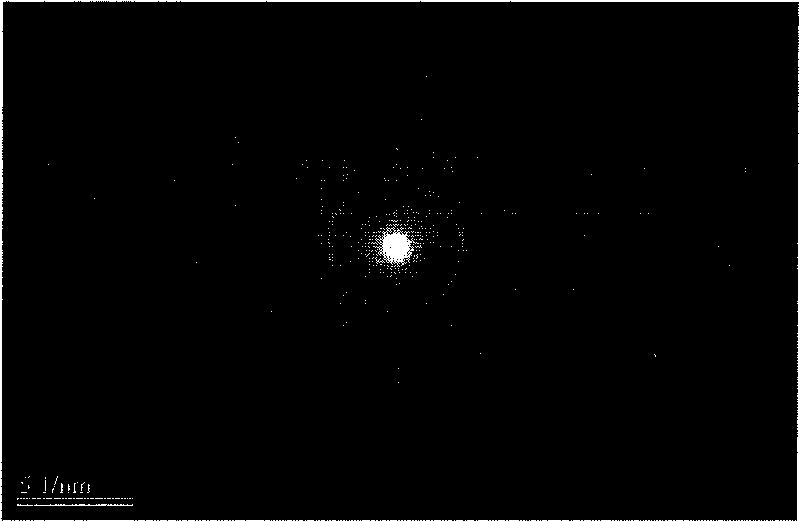

[0033] XRD results such as figure 1 as shown, figure 2 It is TEM image (a) and TEM fine structure image (b), image 3 is an electron diffraction pattern. The phases are anatase and brookite, mainly anatase.

[0034] In step (1), ethanol or a mixture of ethanol and deionized water in any ratio can also be used as the reaction medium, configured as a 0.05mol / L titanium sulfate solution for the reaction,...

Embodiment 2

[0037] (1) With titanium tetrachloride as the titanium source, put the mixture of ethanol / deionized water=1:0.5 (volume ratio) in the ice-water bath in the fume hood, and gradually add TiCl dropwise while stirring. 4 Be made into the stock solution of the concentration of 0.2mol / L, this solution is light golden yellow. Take 10ml of the stock solution and add deionized water (or ethanol, or a mixture of ethanol and deionized water in any ratio, the result is the same) to dilute to 50ml, pour it into a 100ml polytetrafluoroethylene microwave reactor, at 1.0Mpa about 180 React at ℃ for 20 minutes, and cool to room temperature to obtain a milky white suspension;

[0038] (2) Centrifuge at high speed, take the solid and wash until there is no Cl - Finally, wash with absolute ethanol for 1 to 2 times, and vacuum dry at 80° C. for 1.5 hours to obtain nano-titanium dioxide particles.

[0039] Characterization results, XRD results such as Figure 5 as shown, Figure 6 It is TEM ima...

Embodiment 3

[0041](1) Use metatitanic acid as the titanium source and deionized water as the reaction medium to prepare a 0.25mol / L metatitanic acid solution, take 5ml and add deionized water (or ethanol, or ethanol and deionized water in any ratio) The mixed solution formed, the result is the same) diluted to 50ml, poured into a polytetrafluoroethylene microwave reactor with a volume of 100ml, reacted at 2.0Mpa, 210°C for 15min, cooled to room temperature, and obtained a milky white suspension;

[0042] (2) ultrafiltration, get solid washing to no SO 4 2- Till this time (neutral at this time), finally wash with absolute ethanol for 1-2 times, and vacuum-dry at 60°C for 2 hours to obtain nano titanium dioxide particles.

[0043] Characterization results, XRD results such as Figure 8 as shown, Figure 9 It is TEM image (a) and TEM fine structure image (b), Figure 10 is an electron diffraction pattern. The phases are anatase and brookite, mainly anatase.

[0044] In step (1), ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com