GaN-based LED chip extending and growing method for reducing dislocation defects

A technology of LED chips and epitaxial growth, which is applied in the field of optoelectronics, can solve problems such as increased defects, and achieve the effect of improving crystal quality, high quality, and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

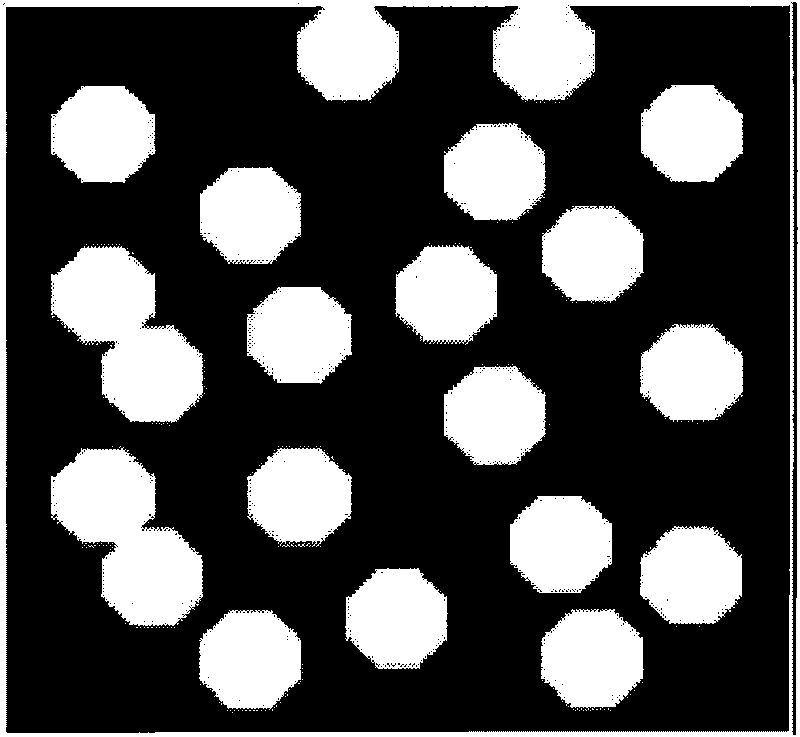

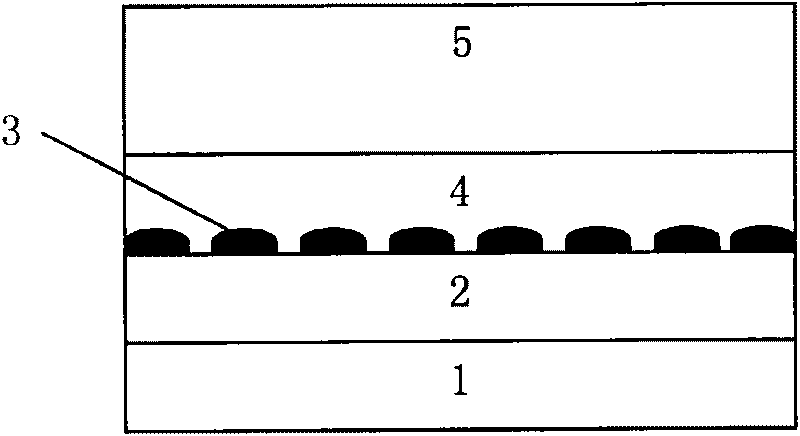

[0018] First put the sapphire substrate 1 into the reaction chamber of the MOCVD (metal organic chemical vapor deposition) growth furnace, and the reaction chamber is in the H 2 Heat the sapphire substrate to 1100°C for 15 minutes in the atmosphere, then lower the temperature to 535°C for 10 minutes, and grow a low-temperature GaN buffer layer with a thickness of 30nm on the substrate. The source material used is trimethylgallium and NH 3 . Then the temperature of the reaction chamber is raised to 1060° C. within 8 minutes. During this process, the low-temperature GaN buffer layer is thermally annealed to recrystallize it, and a high-temperature non-doped GaN layer 2 with a thickness of 100nm-2000nm is grown at this temperature. Then pass Cp alone in the reaction chamber 2 Mg (magnesocene) source and NH 3 , the two react to form a MgN composite 3, uniformly covering the high-temperature GaN layer 2, and passing through the CP 2 The Mg time is 3 minutes, and the thickness o...

Embodiment 2

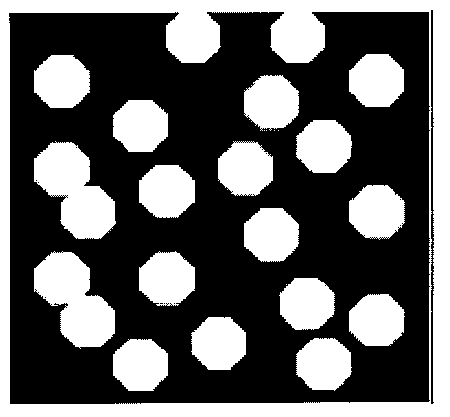

[0021] Put the SiC substrate 1 into the reaction chamber of the MOCVD growth furnace first, and the reaction chamber is in the H 2 Heat the substrate to 1100°C for 15 minutes in the atmosphere, then lower the temperature to 1000°C-1100°C in 3 minutes, and grow a high-temperature AlxGa1-xN buffer layer with a thickness of 10nm-200nm on the substrate, where 03 and CP 2 Mg, forming a MgN mask. A 1 um thick high temperature non-doped GaN layer 4 is then grown subsequently on the MgN cap. Finally, other epitaxial materials 5 for epitaxial GaN-based LED chips include Si-doped n-type GaN, InGaN / GaN multiple quantum wells, and Mg-doped GaN.

Embodiment 3

[0023] First put the Si substrate 1 into the reaction chamber of the MOCVD growth furnace, and the reaction chamber is in the H 2Heat up the Si substrate to 1100°C for 15 minutes in the atmosphere, then lower the temperature to 1000°C for 5 minutes, and grow a 10nm-30nm high-temperature AlxGa1-xN buffer layer on the substrate, where 03 and CP 2 Mg, forming a magnesium nitride mask 3 . A 1 um thick high temperature non-doped GaN layer 4 is then grown subsequently on the MgN cap. Finally, other epitaxial materials 5 for epitaxial GaN-based LED chips include Si-doped n-type GaN, InGaN / GaN multiple quantum wells, and Mg-doped GaN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com