Long-acting low-corrosiveness feed mould inhibitor

A corrosive and antifungal technology, applied in the field of feed antifungal, can solve the problems of high health hazards for production personnel, less antifungal effect than propionic acid, and high corrosiveness of production equipment, so as to improve the antifungal effect and enhance the Anti-mildew and bacteriostatic effect, the effect of prolonging the life of the ring die

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 1200 g of propionic acid and 200 g of ammonium bicarbonate in parts by mass, and add them into the reactor. The temperature is controlled at 80° C., and the stirring speed is 120 rpm. After reacting for 4 hours, add 100 g of ammonium bicarbonate, 15 g of acetic acid, 20 g of benzoic acid, 15 g of sorbic acid, 20 g of citric acid, and 25 g of ethanol, and continue the reaction for 3 hours to obtain a fungicide product for feed. Above-mentioned product is liquid, and pH value is 5, and the consumption that directly adds in feed is 400g / ton feed. After mixing 300g of liquid product and 500g of rice bran, the dosage ratio in the feed is 1000g / ton of feed.

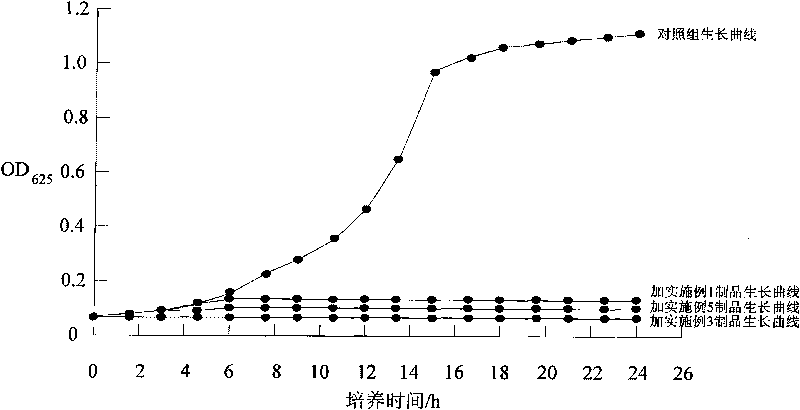

[0030] The mensuration of embodiment 1 product antibacterial effect

[0031] 1, the mensuration of embodiment 1 product minimum inhibitory concentration (MIC):

[0032] Bacteria (Staphylococcus aureus, Escherichia coli, Salmonella, Bacillus subtilis) and molds (Penicillium, Aspergillus) were collected separately,...

Embodiment 2

[0044] Weigh 2,500 g of propionic acid and 900 g of ammonium bicarbonate in parts by mass, and add them into the reactor. The temperature is controlled at 75° C., and the stirring speed is 100 rpm. After 4 hours of reaction, 600 g of ammonium bicarbonate, 200 g of acetic acid, 400 g of benzoic acid, 200 g of sorbic acid, 400 g of citric acid and 400 g of ethanol were added, and the reaction was continued for 4 hours to obtain a fungicide product for feed. Above-mentioned product is liquid, and pH value is 5, and the consumption directly added in feed is 450g / ton feed. After mixing 350g of liquid product, 100g of white carbon black and 450g of vermiculite, the dosage ratio in the feed is 1500 / ton of feed.

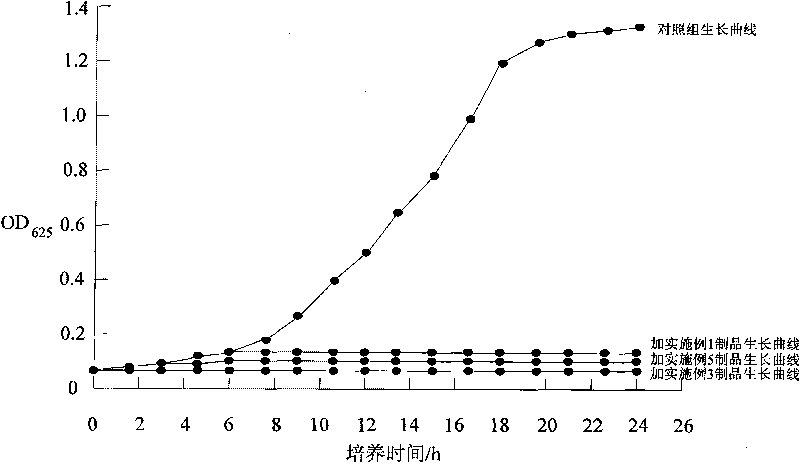

[0045] The mensuration of embodiment 2 products antibacterial effect

[0046] 1. The measurement of the minimum inhibitory concentration (MIC) of the product of Example 2: its test method is the same as that described in Example 1, and the measurement results are shown in T...

Embodiment 3

[0053]Weigh 3500g of propionic acid and 1600g of ammonium bicarbonate in parts by mass, and add them into the reactor, the temperature is controlled at 85°C, and the stirring speed is 120 rpm. After reacting for 4 hours, 900 g of ammonium bicarbonate, 500 g of acetic acid, 800 g of benzoic acid, 500 g of sorbic acid, 800 g of citric acid and 800 g of ethanol were added, and the reaction was continued for 3 hours to obtain a fungicide product for feed. Above-mentioned product is liquid, and pH value is 5.5, and the dosage directly added in feed is 500g / ton feed. After mixing 400g of liquid product, 100g of rice bran and 500g of zeolite powder, the dosage ratio in the feed is 1000g / ton of feed.

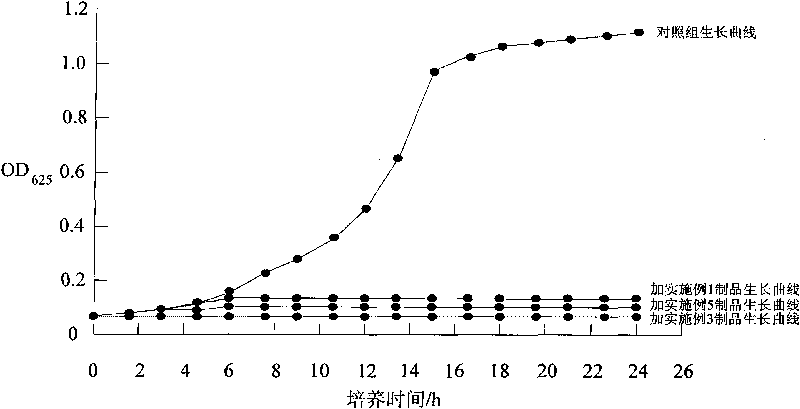

[0054] The mensuration of embodiment 3 products antibacterial effect

[0055] 1. The measurement of the minimum inhibitory concentration (MIC) of the product of Example 3: its test method is the same as that described in Example 1, and the measurement results are shown in Table 3-1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com