Multi-arm star polyester/hyperbranched polyglycidyl ether and preparation method thereof

A technology of polyglycidyl ether and glycidyl ether, which is used in pharmaceutical formulations, medical preparations with non-active ingredients, and pharmaceutical sciences, etc., can solve problems such as organ damage, non-biodegradability, etc., and achieve a long sustained release time. , the effect of increasing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

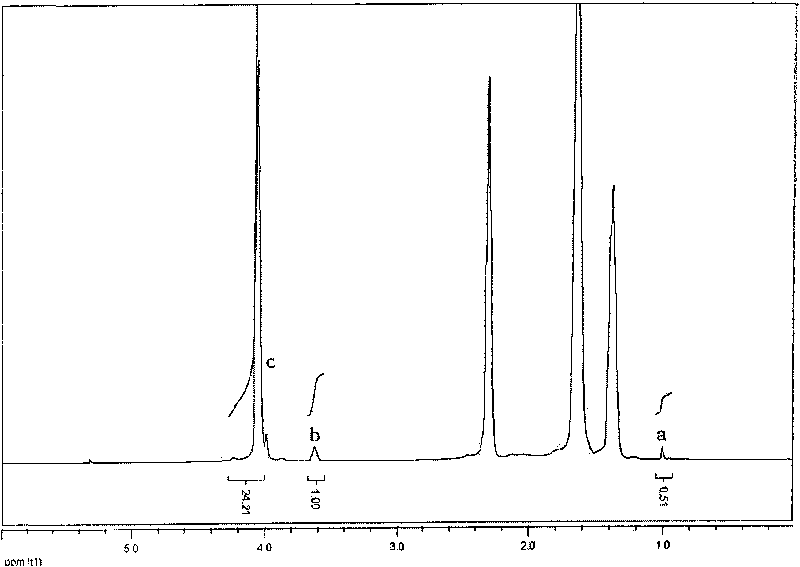

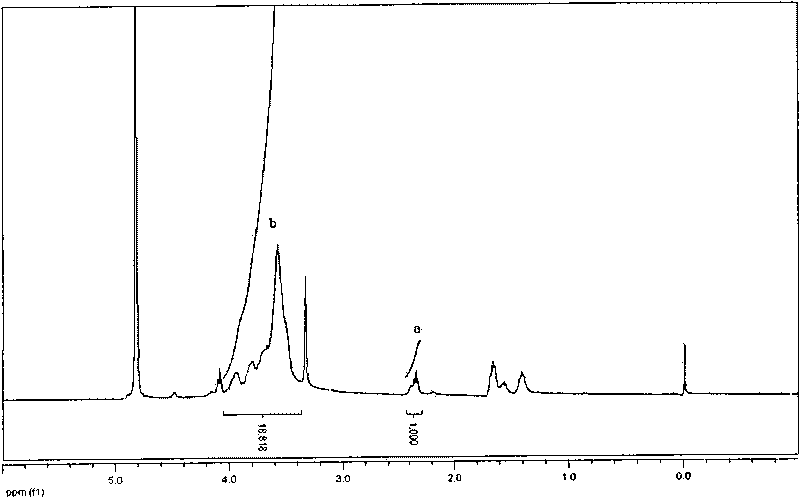

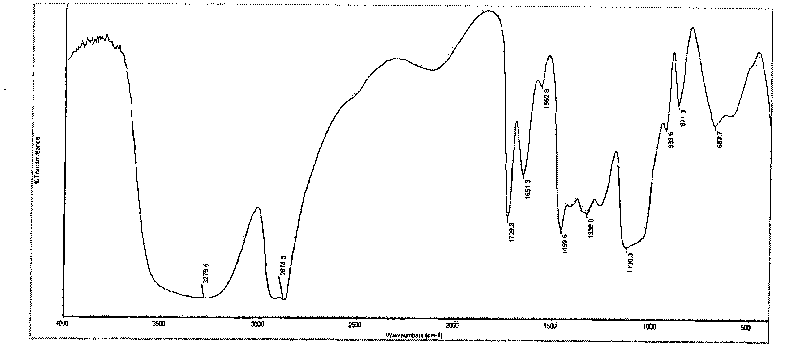

Image

Examples

Embodiment 1

[0042] Mix 0.1 part of pentaerythritol core molecule with 30 parts of purified lactide, after vacuum drying, add 0.03 part of catalyst zinc powder to mix, use an oil pump to vacuumize and dry at room temperature for 10 hours, vacuum seal the tube at 110°C for 120 hours, cool Afterwards, the multi-arm star-shaped biodegradable polyester is obtained by the commonly used polyester purification method; 1 part of the multi-arm star-shaped biodegradable polyester obtained in the above steps is vacuum-dried and dissolved in 10 parts of dry dichloromethane In a solvent, add 0.1 part of sodium methoxide to react at a temperature of 50 °C in a dry atmosphere to obtain a macromolecular initiator, then add 0.01 part of glycidyl ether dropwise, react at a temperature of 0 °C for 48 hours, and purify it with a dialysis membrane with a pore size of 3000 after cooling. A multi-arm star polyester / hyperbranched polyglycidyl ether is obtained.

Embodiment 2

[0044] Mix 0.5 parts of trimethylolethane core molecules with 35 parts of purified ε-caprolactone, and after vacuum drying, add 0.01 parts of the catalyst stannous octoate to mix, vacuumize with an oil pump and dry at 60°C for 1 hour, vacuum The sealed tube was reacted at 100°C for 80 hours, and after cooling, the multi-armed star-shaped biodegradable polyester was obtained by the commonly used polyester purification method; after the 5 parts of the multi-armed star-shaped biodegradable polyester prepared in the above steps were vacuum-dried , dissolved in 25 parts of dry tetrahydrofuran solvent, in a dry atmosphere at a temperature of 130 ° C, add 5 parts of potassium methylate to react to obtain a macromolecular initiator, then add 10 parts of glycidyl ether dropwise, react at a temperature of 20 ° C for 30 hours, after cooling The multi-arm star polyester / hyperbranched polyglycidyl ether is obtained by purifying with a dialysis membrane with a pore size of 3000.

Embodiment 3

[0046] Mix 10 parts of polyester-64-hydroxy-1-carboxy-bismethylolpropionic acid core molecule with 100 parts of purified lactide, after vacuum drying, add 5 parts of catalyst zinc powder and mix, and use an oil pump to evacuate Dry at 100°C for 2 hours, vacuum-seal the tube and react at 180°C for 12 hours. After cooling, use the usual polyester purification method to obtain a multi-armed star-shaped biodegradable polyester; After the biodegradable polyester was vacuum-dried, it was dissolved in 500 parts of dry N, N-dimethylformamide and ethyl acetate solvent (3:2 mass ratio), and 3 parts of The macromolecular initiator was obtained by the reaction of potassium naphthalene, and then 0.4 parts of glycidyl ether was added dropwise, and reacted at a temperature of 30°C for 40 hours. After cooling, it was purified with a dialysis membrane with a pore size of 10,000 to obtain a multi-armed star-shaped polyester / hyperbranched polyglycidyl ether .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com