Copolymer of fibroin and poly L-lactic acid and preparation method and application thereof

A silk protein and copolymer technology, applied in the field of silk protein and poly-L-lactic acid copolymer and its preparation, can solve the problem of no research report

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

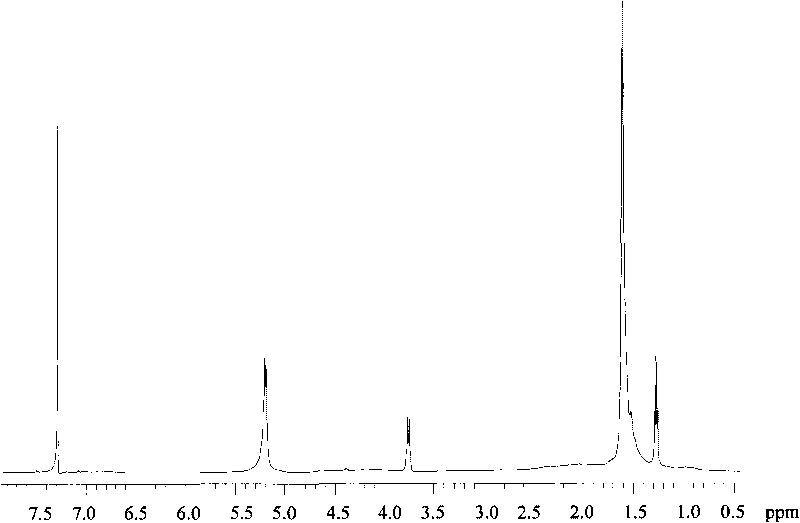

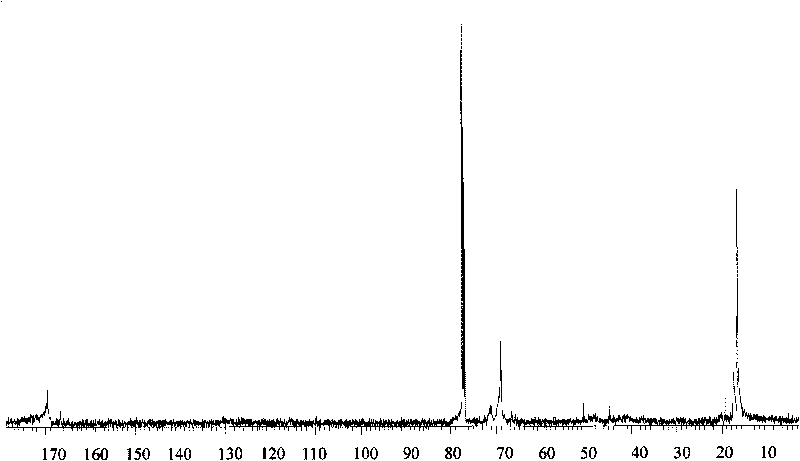

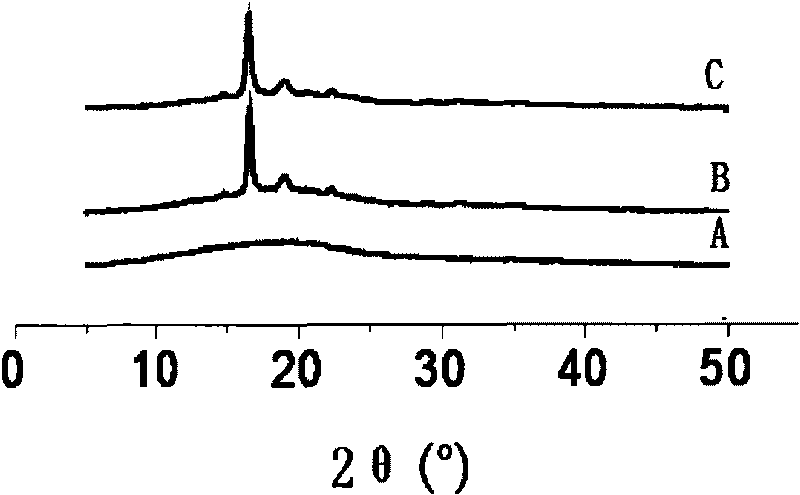

Embodiment 1

[0063] L-lactide, SnCl 2 / p-toluenesulfonic acid catalyst system (SnCl 2 The molar content accounts for 50% of the entire catalyst system, SnCl 2 The amount used is 0.5wt% of L-lactide. ) into the polymerization kettle. The pressure of the system was gradually reduced to 0 mmHg (manometer reading) and then sealed. The reaction temperature was 170° C., and the reaction was carried out for 10 hours to obtain a poly-L-lactic acid prepolymer (molecular weight: 12,000). Then dehydrated silk protein powder (the number-average molecular mass is 3000, the mass ratio of L-lactide to silk protein is 4:1) is added into the reactor, and the reaction condition is maintained for 10 hours. Then the temperature was lowered to 140° C., and a solid phase reaction was carried out for 2 hours. After the polymerization, the purified copolymer of silk protein and poly-L-lactic acid is a yellow powder with a molecular weight of 16,000, a yield of 73%, and a specific rotation of 93°.

Embodiment 2

[0065] L-lactide, SnCl 2 / naphthalenesulfonic acid catalyst system (SnCl 2 The dosage is 0.5wt% of L-lactide, SnCl 2 The molar content accounts for 50% of the whole catalyst system) into the polymerization tank. The pressure of the system was gradually reduced to 10 mm Hg and then sealed. The reaction temperature was 170° C. and the reaction time was 5 hours to obtain a poly-L-lactic acid prepolymer (molecular weight: 8,000). Then dehydrated silk protein powder (the number-average molecular mass is 3000, the mass ratio of L-lactide to silk protein is 6:1) was added into the reactor, and the reaction conditions were maintained for 7 hours. Then the temperature was lowered to 130° C., and the solid state reaction was carried out for 10 hours. After the polymerization, the purified copolymer was a yellow powder with a molecular weight of 24,000, a yield of 73%, a melting point of 126°C and a specific rotation of 113°.

Embodiment 3

[0067] L-lactide, stannous isooctanoate / naphthalenesulfonic acid catalyst system (the consumption of stannous isooctanoate is 0.5wt% of L-lactide, and the molar content of stannous isooctanoate accounts for 50% of the whole catalyst system) Add to the polymerization kettle. The pressure of the system was gradually reduced to 2 mm Hg and then sealed, the reaction temperature was 170° C., and the reaction time was 2 hours to obtain a poly-L-lactic acid prepolymer (molecular weight: 5,000). Then dehydrated silk protein powder (the number-average molecular mass is 1000, and the mass ratio of L-lactide to silk protein is 10:1.) was added to the reaction kettle, and the reaction conditions were maintained to continue the reaction for 7 hours. Then the temperature was lowered to 140° C., and the solid phase reaction ended after 10 hours. The purified copolymer is a yellow powder with a molecular weight of 29,000, a yield of 74%, a melting point of 130°C and a specific rotation of 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific rotation | aaaaa | aaaaa |

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com