Production technique of copper strips for solar modules

A technology for solar cells and production processes, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult processing, unstable oxygen content, and high performance requirements of copper strips for solar cell modules, and achieves no residual liquid spots, The effect of optimized annealing process and superior mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

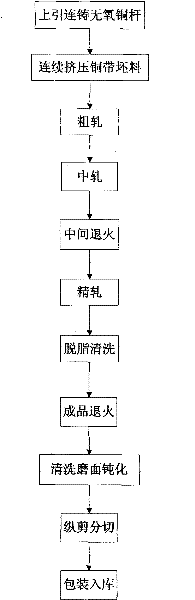

[0028] Such as figure 1 As shown, the process scheme adopted by the present invention is as follows: upward continuous casting oxygen-free copper rod-continuous extruded copper strip blank-rough rolling-intermediate rolling-intermediate annealing-finishing rolling-degreasing cleaning-finished product Annealing-cleaning and passivation of grinding surface-slitting and cutting-packaging and storage

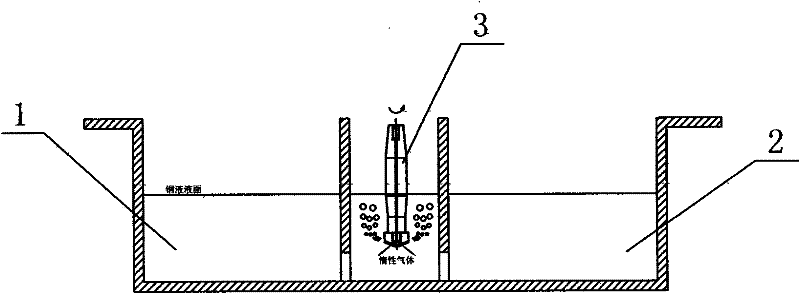

[0029] 1. Upward continuous casting oxygen-free copper rod

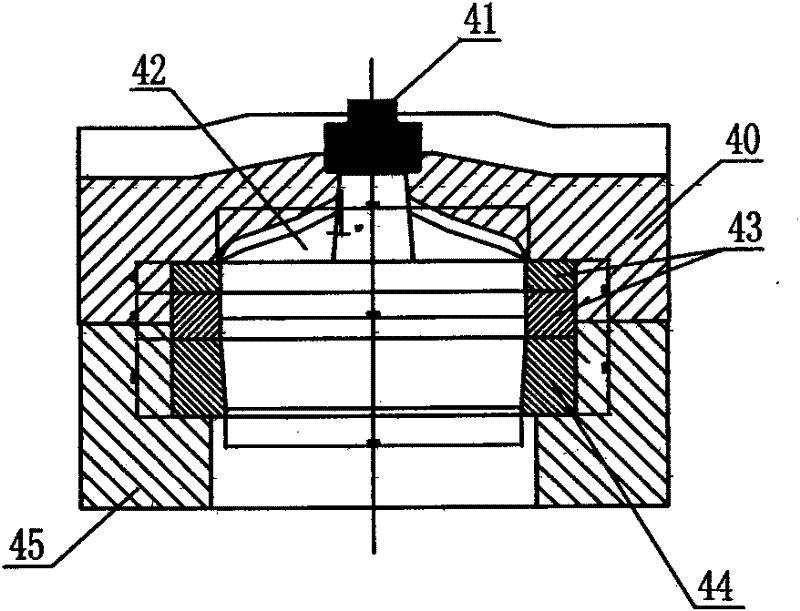

[0030] Select Grade A electrolytic copper as the raw material. After preheating and drying the electrolytic copper, it is melted in a melting furnace at 1150℃±10℃, the water pressure of the crystallizer is 2~4MPa, and the temperature of the crystallizer outlet water is controlled at 35℃~50℃. The furnace is insulated, and the copper liquid temperature is 1150℃±10℃. use figure 2 The shown on-line degassing and deoxygenating stirring device, the copper liquid is filled with 99.996% of argon or nitrogen, and the metered argon or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com