Method for preparing tubular support dense oxide film

A dense oxide, tubular support technology, applied in the field of selective separation, can solve the problem that the mechanical strength cannot meet the requirements of industrialization, and achieve the effect of good mechanical performance and dense film surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

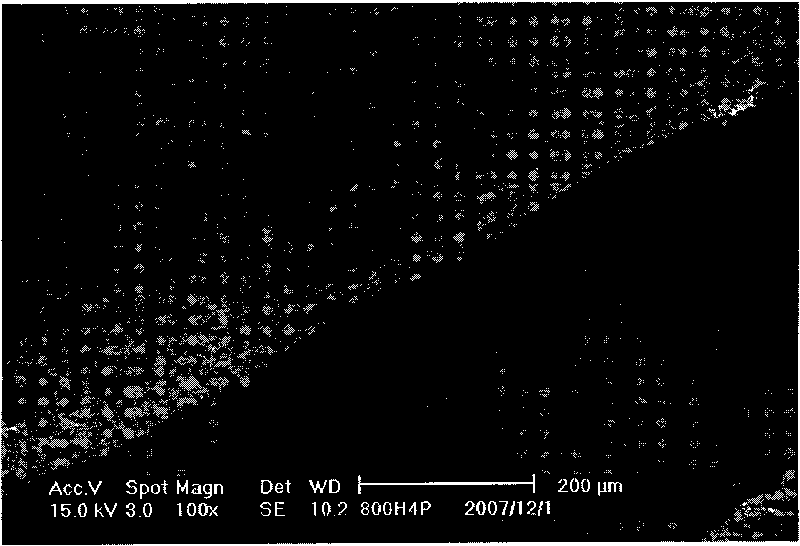

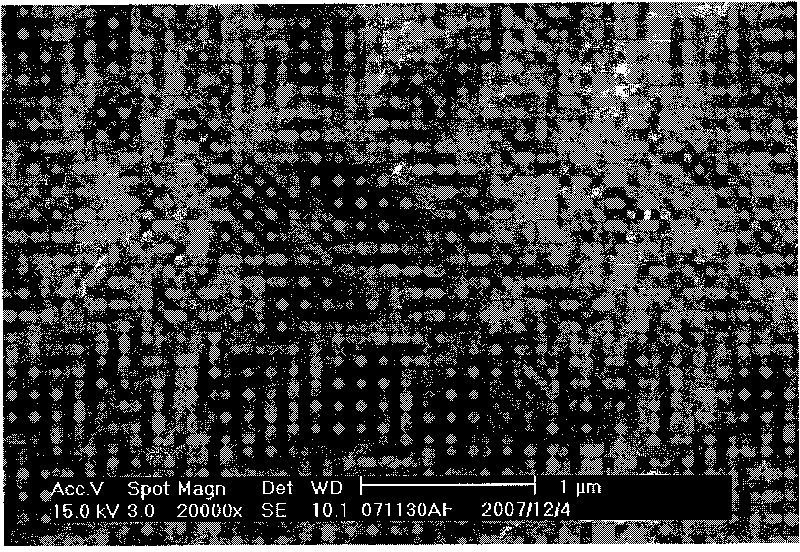

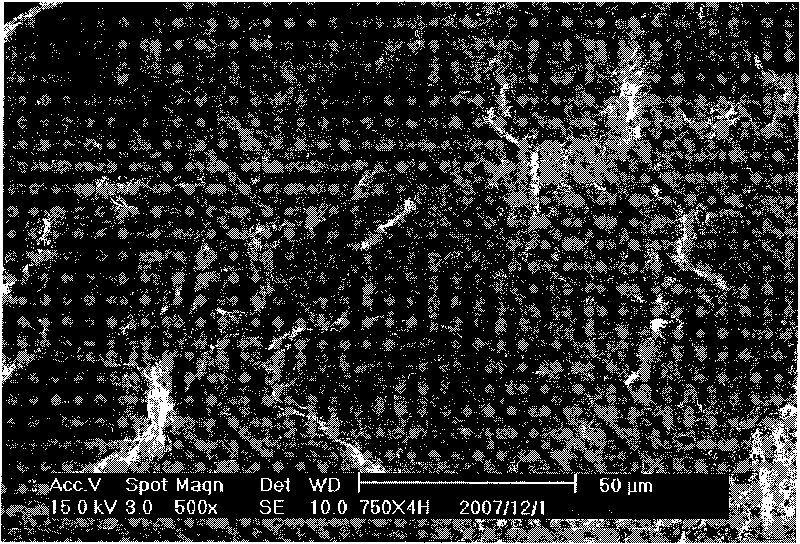

[0023] The support tube is a ceramic tube composed of oxygen, silicon, aluminum, sodium, calcium, magnesium, potassium, titanium, iron and trace amounts of strontium, zirconium, and rubidium. It contains a through hole with a diameter of 50 μm, an inner diameter of 10 mm, and an outer diameter of 15 mm. . First, the support tube is cleaned in ethanol and placed in a muffle furnace. The temperature of the muffle furnace is raised to 1100°C at a rate of 5°C / min, kept for 2 hours, and naturally cooled to room temperature. The dense oxide component is prepared by the sol method. It is a doped perovskite structure material. The specific method is to accurately weigh the nitrates of strontium, titanium, iron and copper, and add urea and ethylene glycol according to the ratio of total metal ion number: urea: ethylene glycol molar ratio of 1: 2: 3, with urea as Complexing agent, ethylene glycol as a dispersant, using ammonia water to adjust the pH of the sol to 6.5, raising the tempe...

Embodiment 2

[0025] The support tube is a ceramic tube containing oxygen, silicon, aluminum, sodium, calcium, magnesium, potassium, titanium, iron and trace amounts of strontium, zirconium, and rubidium. The tube wall has a through hole with a diameter of 5 μm, and the inner diameter of the ceramic tube is 15 mm. The outer diameter is 20mm. First, the support tube is cleaned in ethanol and placed in a muffle furnace. The temperature of the muffle furnace is raised to 1100°C at a rate of 2.5°C / min, kept for 1h, and naturally cooled to room temperature. The dense oxide is a doped perovskite structure prepared by a sol-gel method. Accurately weigh the nitrates of strontium, titanium, iron and manganese, add citric acid and ethylene glycol according to the molar ratio of the total number of metal ions: citric acid: ethylene glycol in a ratio of 1:3:3, and the complexation of the sol Citric acid was used as the agent, ethylene glycol was used as the dispersant, the pH of the solution was adjust...

Embodiment 3

[0027]A ceramic tube containing oxygen, silicon, aluminum, calcium, magnesium, potassium, titanium, vanadium, iron and trace amounts of strontium, zirconium, and rubidium is used as a support tube. The tube wall has a through hole with a diameter of 10 μm, and the inner diameter of the support tube is 12 mm. , with an outer diameter of 18 mm. First, the support tube was cleaned in ethanol and placed in a muffle furnace. The temperature of the muffle furnace was raised to 1000 °C at a rate of 5 °C / min, kept for 2 hours, and then naturally cooled to room temperature. The dense oxide is a doped perovskite structure prepared by a sol-gel method. Accurately weigh the nitrates of zirconium, titanium, iron and copper, add urea and ethylene glycol according to the molar ratio of the total number of metal ions: urea: ethylene glycol is 1:3:4, and adjust the pH of the sol with ammonia water =8, heat to 80°C, stir for 6 hours to form a gel, let it stand still, immerse the support tube in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com