Method for processing drinking water and device using same

A technology of drinking water treatment and treatment method, which is applied in the field of drinking water treatment method and its device, and can solve the problems of low energy utilization rate, electrode corrosion, complicated power supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

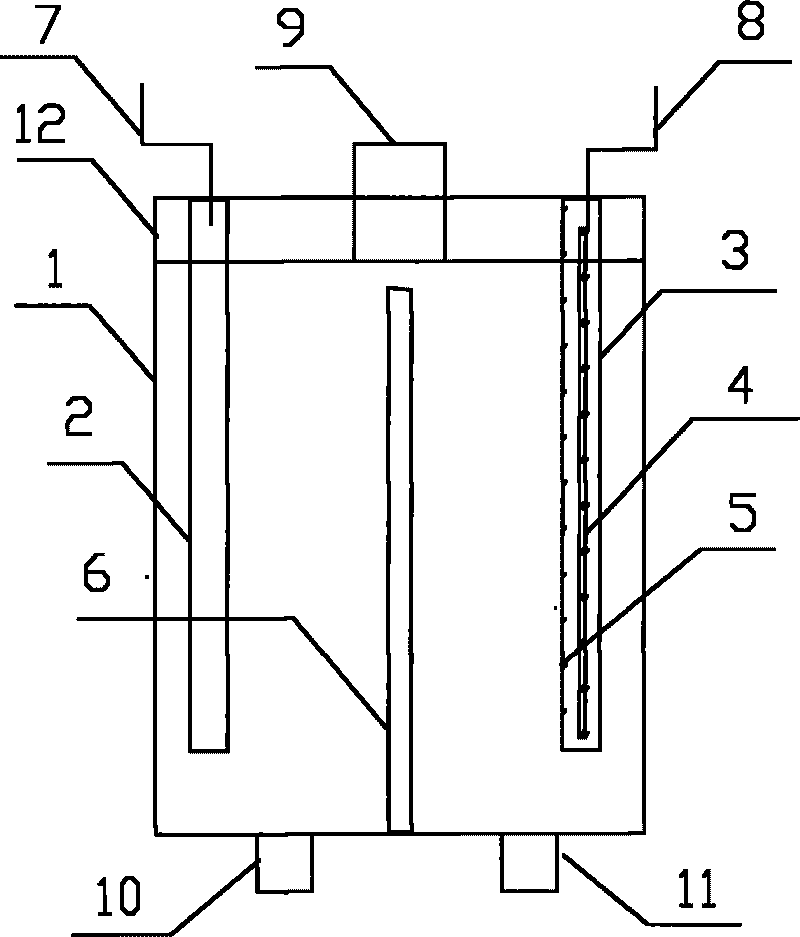

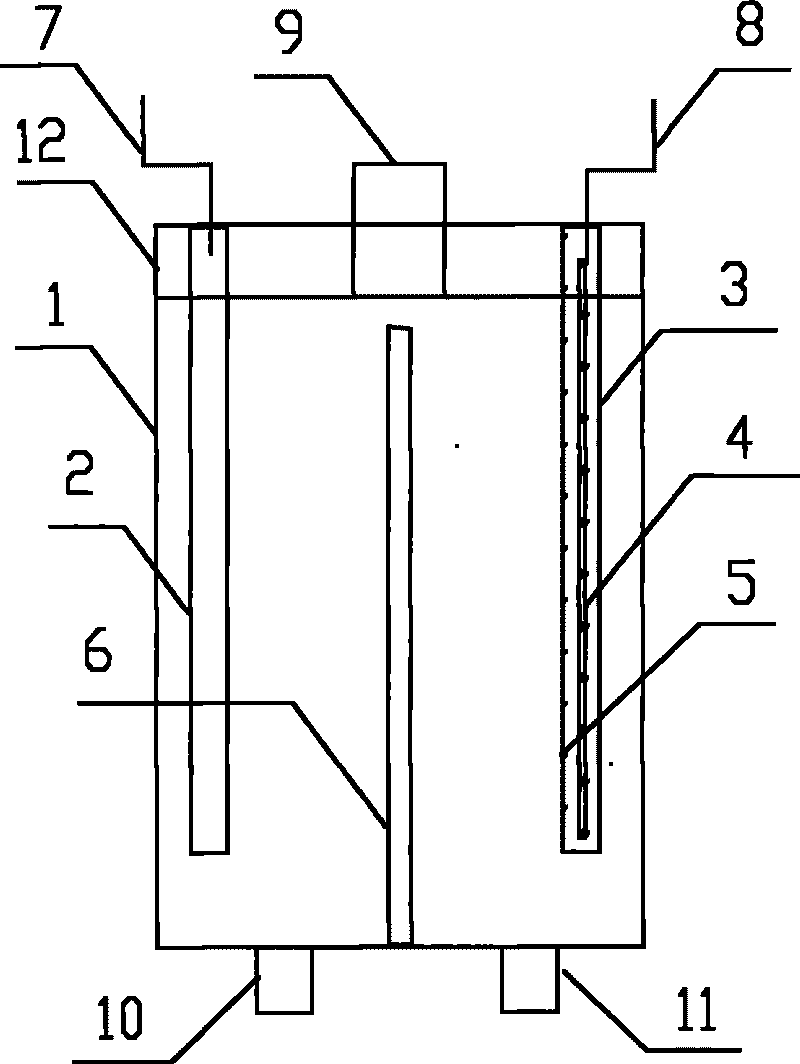

Image

Examples

Embodiment 1

[0029] After passing water into the reaction vessel, turn on the DC power supply, apply 400V voltage to the cathode and anode, and electrolytic reaction occurs in the reaction vessel. Continue to increase the voltage to 500-1500V, the gas at the small hole is broken down, and plasma is formed to treat the influent water.

[0030] Experimental conditions: the volume of the container is 1L; the initial concentration of E. coli is 10 3 CFU / ml; phenol concentration 2mg / l; initial pH 6.5; silver ion concentration 3mg / L; current 25mA, voltage 500-1500V, constant current mode.

[0031] Detection conditions: Escherichia coli is determined by counting method, phenol concentration is determined by high performance liquid chromatography, pH is measured by acidity meter, and silver ion concentration is determined by atomic absorption method. The obtained data are shown in Table 1.

[0032] Table 1

[0033] Influent residence time

Embodiment 2

[0035] After the water is passed through the reaction vessel, the DC pulse power supply is turned on to treat the influent water.

[0036] Experimental conditions: the volume of the container is 1L; the initial concentration of E. coli is 10 3 CFU / ml; phenol concentration 2 mg / l; initial pH 6.5; silver ion concentration 3 mg / L; pulse voltage peak value 1000V; pulse frequency 3000 Hz; input power 50 watts. Escherichia coli was determined by counting method, phenol concentration was determined by high performance liquid chromatography, pH was measured by acidity meter, and silver ion concentration was determined by atomic absorption method. The obtained data are shown in Table 2.

[0037] Table 2

[0038] Residence time (min)

[0039] Residence time (min)

[0040] The present invention utilizes the electrochemical process of discharge plasma, which has physical effects and chemical effects at the same time. The physical effects generate ultraviolet light an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com