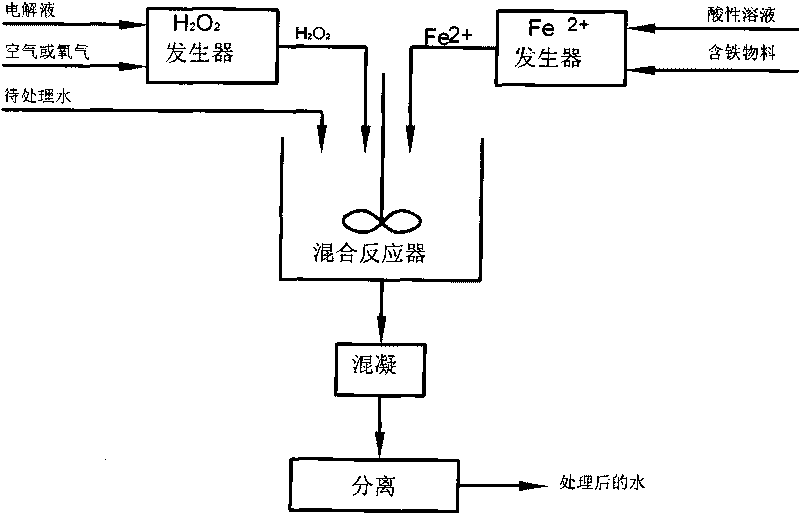

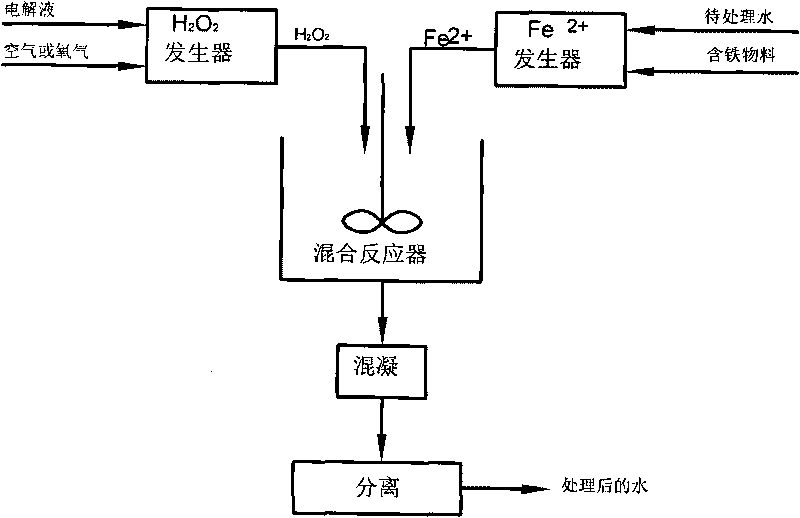

Method for preparing Fenton reagent on site for treating waste water

A technology for on-site preparation and treatment of wastewater, applied in the field of water treatment, can solve the problems of easy electrode pollution, low efficiency, low working current density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

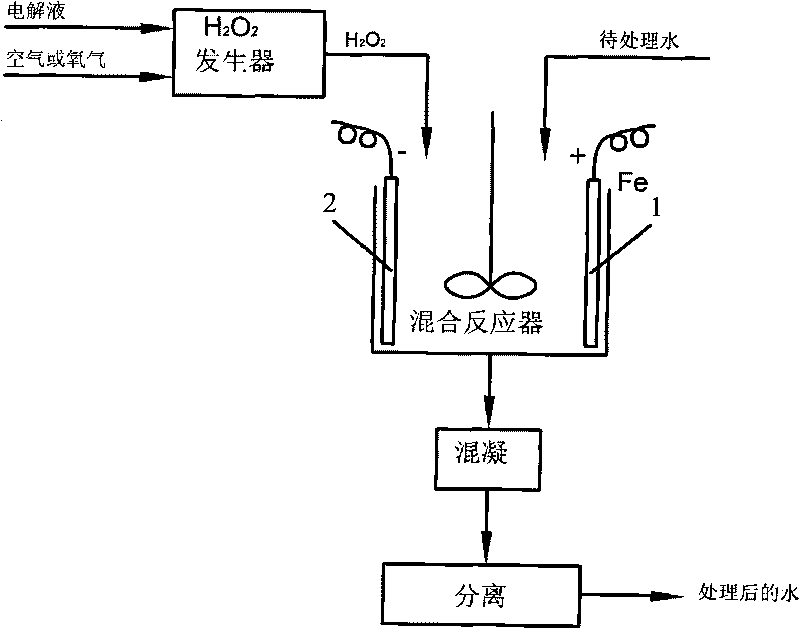

[0083] In a diaphragmless electrochemical H 2 o 2 generator, see Figure 4 , with graphite and polytetrafluoroethylene gas diffusion electrode prepared by techniques known in the art as the cathode, with stainless steel as the anode, with 0.5mol / L NaOH solution as the electrolyte and feed in at a speed of 2ml / min Generator, the air is fed into the air chamber at a flow rate of 200ml / min, the air outlet is placed 30cm below the water surface, and 500A / m is fed between the anode and the cathode 2 direct current, the working temperature is 10°C, and the outflowing electrolyte contains H 2 o 2 0.4mol / L or so, the current efficiency is 46.32%. In another diaphragmless electrochemical Fe 2+ generator, see Figure 7 , with iron plates as cathode and anode, with 0.5mol / L H 2 SO 4 It is the electrolyte and passes through the generator at a speed of 1ml / min, and 1000A / m is passed between the anode and the cathode 2 direct current, the working temperature is 10°C, and the outflo...

Embodiment 2

[0085] H in Example 1 2 o 2 The generator uses a polypropylene fiber diaphragm to separate the electrode chamber into a cathode chamber 8 and an anode chamber 7, see Figure 5 , the gas diffusion electrode prepared with X72 carbon black and polytetrafluoroethylene is used as the cathode, and the titanium-supported platinum is used as the anode, and H 2 SO 4 0.5mol / L sodium sulfate solution with pH adjusted to 3.0, oxygen is passed into the gas chamber 4 at a flow rate of 10ml / min, the gas outlet is not under pressure, and 50A / m is passed between the anode and the cathode 2 direct current, the working temperature is 25°C, and the outflowing electrolyte II’ contains H 2 o 2 About 0.6mol / L, the current efficiency is 77.20%. Fe described in Example 1 2+ In the generator, use 45# carbon steel mesh as the anode and stainless steel as the cathode, add 100ml of the above wastewater plus sulfuric acid solution to a sulfuric acid content of 0.05mol / L, and feed 3000A / m at 20°C 2 T...

Embodiment 3

[0087] H in Example 2 2 o 2 The diaphragm in the generator was changed to Nafion 117 cation exchange membrane, the gas diffusion electrode made of graphite, acetylene black and polytetrafluoroethylene was used as the cathode, the nickel mesh was used as the anode, and 0.5mol / L potassium sulfate and 0.25mol The mixed solution composed of potassium hydroxide per L is the catholyte, and 20% potassium hydroxide solution is used as the anolyte. chamber, the gas outlet is placed 20cm below the water surface, and 2000A / m is passed between the anode and the cathode 2 direct current, the working temperature is 35°C, and the outflowing electrolyte contains H 2 o 2 1.2mol / L, the current efficiency reaches 96.49%. Fe described in Example 1 2+ In the generator, iron, carbon steel and alloy steel wastes are placed in a titanium basket as the anode, and stainless steel as the cathode, add 20g of sodium sulfate to 1L of the above acid rose red B wastewater, and adjust the pH value with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com