Antistatic agent and method for preparing same

A technology of antistatic agent and formula, which is applied in the field of antistatic agent and its preparation, can solve the problems of no air humidity dependence, antistatic ability influence, high melting point, etc., and achieve the effect of excellent antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The sodium p-styrene sulfonate of 20g is dissolved in deionized water, and its mass concentration is 30%, and in the four-necked flask of packing band stirrer and reflux device, feeds N simultaneously 2 , set the temperature at 60°C, dissolve 60ml of n-butyl methacrylate to remove the inhibitor in tetrahydrofuran and pour it into the reaction system, start stirring, and after about 30min, add the initiator potassium persulfate-sodium bisulfite Solution (dissolve 0.5g potassium persulfate and 0.2g sodium sulfite in 50ml deionized water), put it into a constant pressure dropping funnel, drop p-styrene at a rate of 1 drop every 3 seconds or 2 drops every 5 seconds In the mixed solution of sulfonate and n-butyl methacrylate, the solution changes from light yellow or colorless to slightly white, and finally becomes milky white. The reaction is about 10 hours in total, and the reaction is stopped. Precipitate the product with ethanol and filter it with water at the same time....

Embodiment 2

[0027] Dissolve 10 g of sodium p-styrene sulfonate in deionized water with a mass concentration of 35%, and put it into a four-necked flask with a stirring device, set the temperature at 70 ° C, and dissolve 25 ml of polyethylene glycol methacrylate Alcohol monomethyl ether ester is dissolved in p-styrene sulfonate solution, and N is passed through at the same time 2 , plus initiator azodiisopropylimidazoline, the addition amount is 0.3g. Stop the reaction after reacting for about 10 hours, precipitate the product with methanol, and filter it with water at the same time. After repeated 3 times, take out the product and dry it in vacuum at 50°C for 12 hours to obtain the desired antistatic agent. The biggest feature of this reaction is that the reaction process has obvious The color changes from light yellow to dark red to brown and then to light yellow, and finally the color will become milky white.

Embodiment 3

[0029] Dissolve 25g of sodium p-styrene sulfonate in deionized water to make a concentration of 25%, and put it into a four-necked flask with a stirring device, add 70ml of ethyl methacrylate to the inhibitor after removing the polymerization inhibitor system, and then pass into N 2 , set the temperature to 70°C, and simultaneously dissolve 0.8g of 4,4'-azobis(4-cyanovaleric acid) initiator in 70ml of deionized water to form a solution, and put it into a constant pressure dropping solution funnel. Pass N 2 After half an hour, start to add the initiator dropwise, and control the dropping speed to one drop every 3 seconds or 2 drops every 5 seconds. Stop the reaction after about 8 hours, purify the product with methanol, and finally filter it with water. After repeated several times, take out the product and dry it in vacuum at 50°C for 12 hours to obtain the antistatic agent.

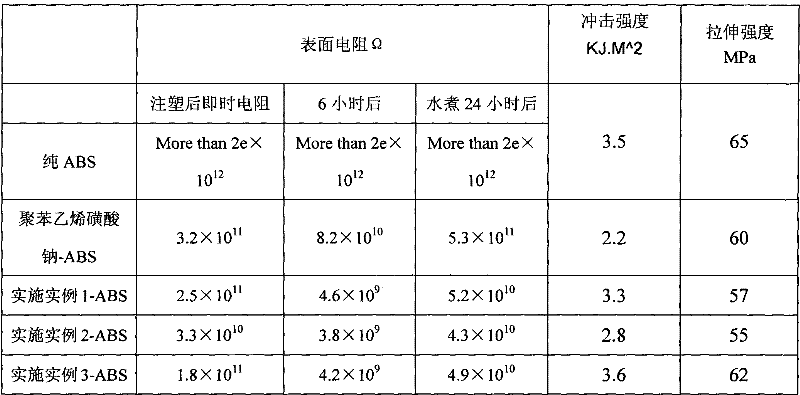

[0030] Grind the antistatic agent obtained from the above examples into a powder of 80 to 100 mesh,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com