Method for treating and utilizing potassium hydrogen tartrate mother liquor

A technology of potassium hydrogen tartrate mother and potassium hydrogen tartrate, which is applied in the field of processing and utilizing potassium hydrogen tartrate mother liquor, can solve the problems of resource waste and difficulty, and achieve the effect of reducing COD content and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

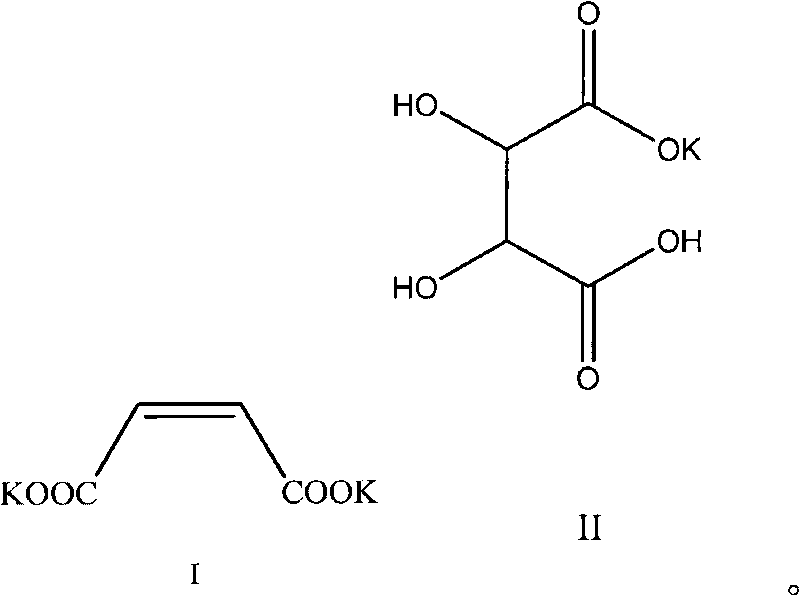

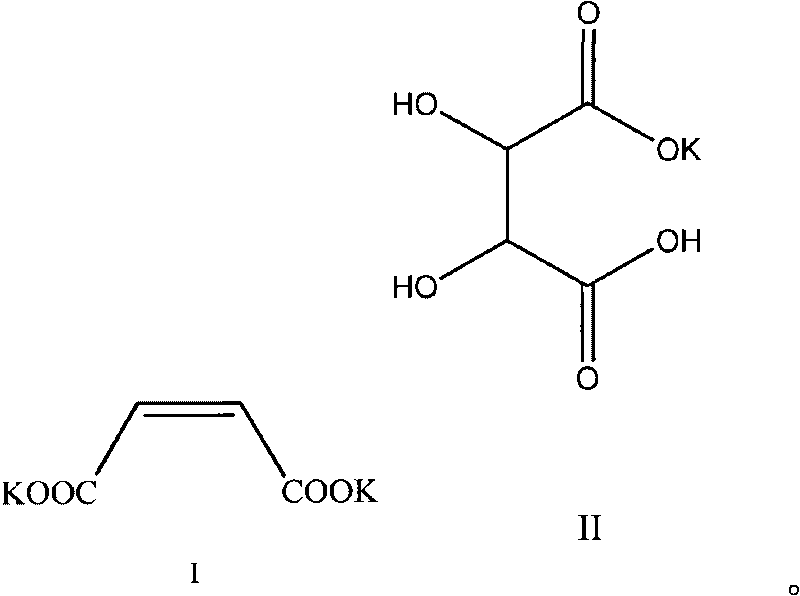

Image

Examples

Embodiment 1

[0015] Get 3 tons of process waste water in the production of DL-potassium hydrogen tartrate, be concentrated to relative density through thin-film evaporator decompression to 1.26 (pomi meter is measured, the same below), obtain 1 ton of concentrated solution, add catalyst (tungsten Na2SO4) 1kg, the temperature is controlled at 70-72 degrees Celsius, slowly add 400kg of hydrogen peroxide with a concentration of 27.5%, and keep the temperature for 24 hours. Thing and reclaim mother liquor, get throw out and obtain potassium hydrogen tartrate product 300kg, purity 95% (determined with 0.5mol / L sodium hydroxide solution titration).

[0016] Utilize the reclaimed mother liquor to carry out recovery in the same way, every 3 tons of secondary use of mother liquor can recover 260kg of product, and the product purity is 85%.

Embodiment 2

[0018] Get 3 tons of process wastewater in the production of DL-potassium hydrogen tartrate, and concentrate it to a relative density of 1.26 through a thin-film evaporator to obtain 1.1 tons of concentrated solution. Add 1.1 kg of catalyst (sodium tungstate) to the concentrated solution, and the temperature is controlled at 70-72 degrees Celsius, slowly add 440 kg of hydrogen peroxide with a concentration of 27.5%, and keep it warm for 24 hours. After the reaction, the reaction solution is heated to 95-100° C., kept warm for 2 hours, then cooled to room temperature, centrifuged, and the precipitate is taken to obtain 285 kg of potassium hydrogen tartrate product. The purity is 95% (determined by titration with 0.5mol / L sodium hydroxide solution).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com