Method for preparing spinelle lithium titanate for lithium ion battery negative electrode material

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve the complexity of process control and increase in production costs, the insignificant improvement of high-current charge and discharge performance, and the difficulty of mass production, etc. problem, to achieve the effect of high current charge and discharge performance, good electrical conductivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

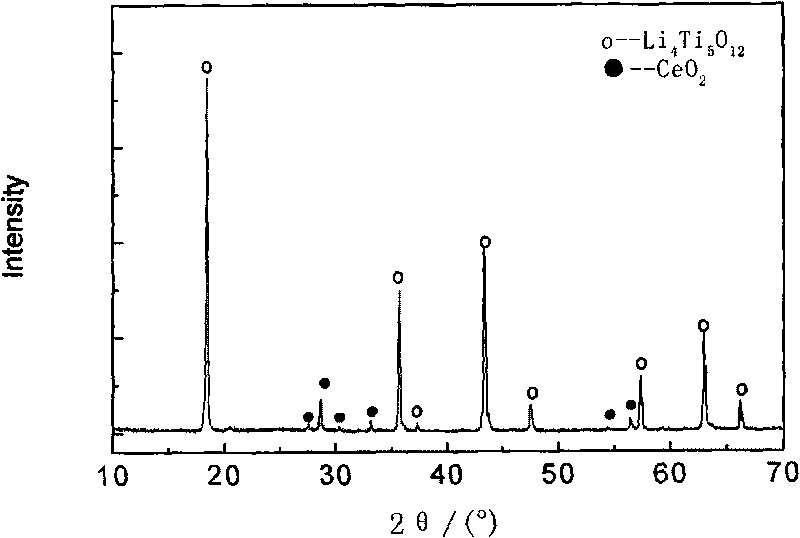

[0030] Weigh Li according to the ratio of molar ratio Li:Ti=1:1.18 2 CO 3 and TiO 2 , by CeO 2 accounted for the prepared Li 4 Ti 5 o 12 / CeO 2 3% of the total mass of the composite electrode material is added to CeO 2 , then add absolute ethanol as a dispersant, grind for 2 hours with a ball mill, mix the raw materials thoroughly, dry in the air, transfer the mixture to a crucible, put it in a muffle furnace, pre-fire at 600 ° C for 6 hours, and then Calcined at 850°C for 10 h to obtain Li 4 Ti 5 o 12 / CeO 2 Composite electrode material.

[0031] A Japanese XRD-7000 X-ray diffraction analyzer was used to analyze the phase structure of the prepared negative electrode material. figure 1 Shown; the negative electrode composite Li 4 Ti 5 o 12 / CeO 2 SEM morphology analysis was carried out as Figure 6 shown.

[0032] will make the Li 4 Ti 5 o 12 / CeO 2 The powder is mixed with acetylene black as a conductive agent and PVDF as a binder in a mass fraction rati...

Embodiment 2

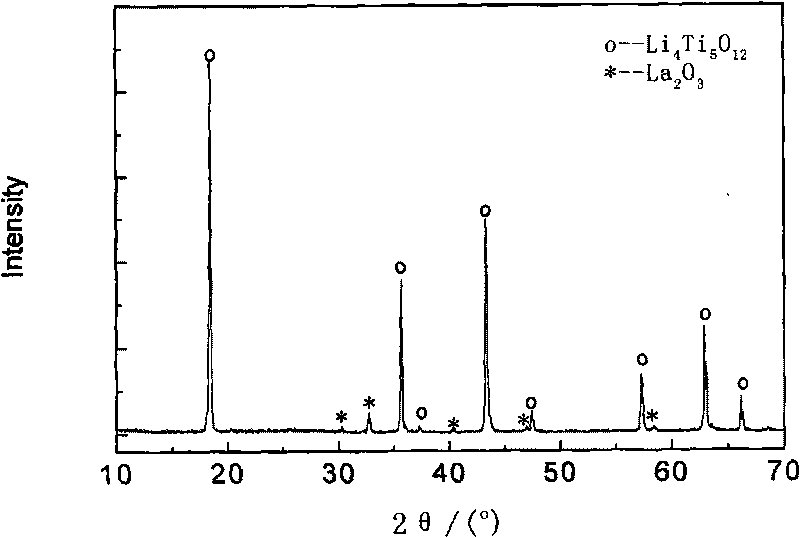

[0034] Weigh Li according to the ratio of molar ratio Li:Ti=1:1.16 2 O and TiO 2 , press La 2 o 3 accounted for the prepared Li 4 Ti 5 o 12 / La 2 o 3 2% of the total mass was added to La(NO 3 ) 3 ·6H 2 O, then add acetone as a dispersant, grind for 3 hours with a ball mill, fully mix the raw materials, dry in the air, transfer the mixture to a crucible, and put it into a muffle furnace for calcination to obtain Li 4 Ti 5 o 12 / La 2 o 3 Composite electrode material. Calcination conditions are the same as in Example 1.

[0035] Li 4 Ti 5 o 12 / La 2 o 3 The powder is subjected to X-ray diffraction phase analysis such as figure 2 As shown, the SEM morphology analysis is as follows Figure 7 shown and the charge-discharge performance test as Figure 11 Curve 2 is shown. Test condition is the same as embodiment 1.

Embodiment 3

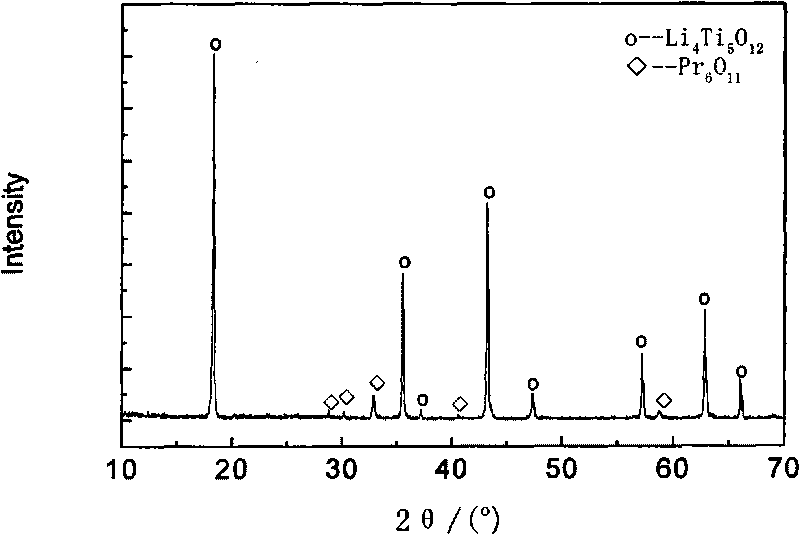

[0037] Weigh LiOH and TiO according to the ratio of molar ratio Li:Ti=1:1.15 2 , press Pr 6 o 11 accounted for the prepared Li 4 Ti 5 o 12 / Pr 6 o 11 Add Pr(OH) in the amount of 0.5% of the total mass of the composite electrode material 3 , then add acetone as a dispersant, grind with a ball mill for 0.5h, mix the raw materials thoroughly, dry in the air, transfer the mixture to a crucible, and put it into a muffle furnace for calcination to obtain Li 4 Ti 5 o 12 / Pr 6 o 11 Composite electrode material. Calcination conditions are the same as in Example 1.

[0038] Li 4 Ti 5 o 12 / Pr 6 o 11 The powder is subjected to X-ray diffraction phase analysis such as image 3 As shown, the SEM morphology analysis is as follows Figure 8 shown and the charge-discharge performance test as Figure 11 Curve 3 shown. Test condition is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com