Method for analyzing total arsenic in glass

An analysis method and glass technology, applied in the field of physical and chemical inspection, can solve the problem of inability to realize simultaneous analysis and determination, and achieve the effects of simple and controllable digestion steps, simple analysis process, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Instruments and reagents

[0034] XS-205 automatic electronic analytical balance (Switzerland, Mettler-Toledo company); Vista Axial CCD Simultaneous ICP-AES Spectrometer (USA, Varian company), charge-coupled detector, dispersion system is echelle grating, concentric atomizer, The frequency is 40.68MHz, and the instrument is controlled by IBM computer and Varian's Vista software system.

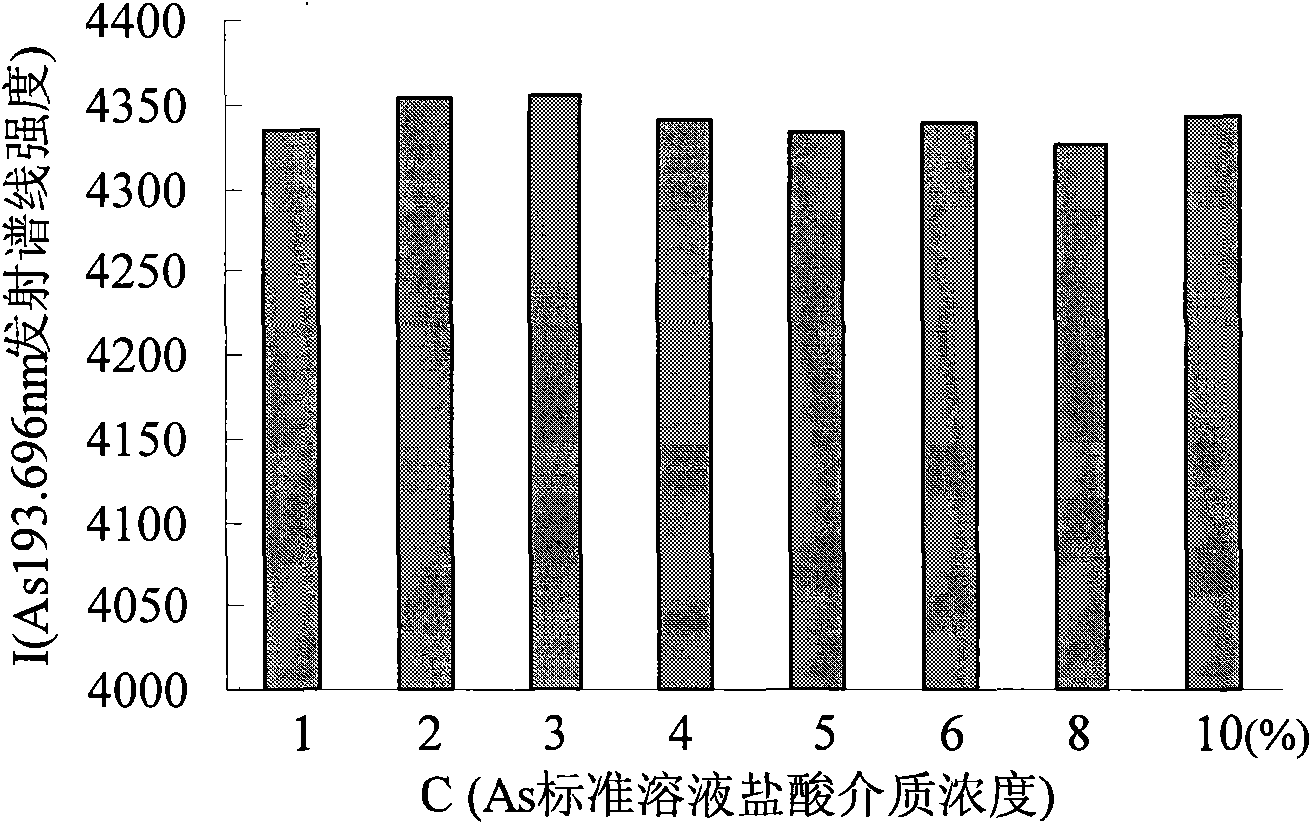

[0035] Instrument working parameters: power 1.1kW, cooling gas flow 15L / min, auxiliary gas flow 1.5L / min, atomizing gas flow 0.8L / min, integration time 5s; repeat times 3 times, stabilization time 20s, sample lifting time 20s , cleaning time 10s, peristaltic pump speed 15rpm; argon purity 99.99%.

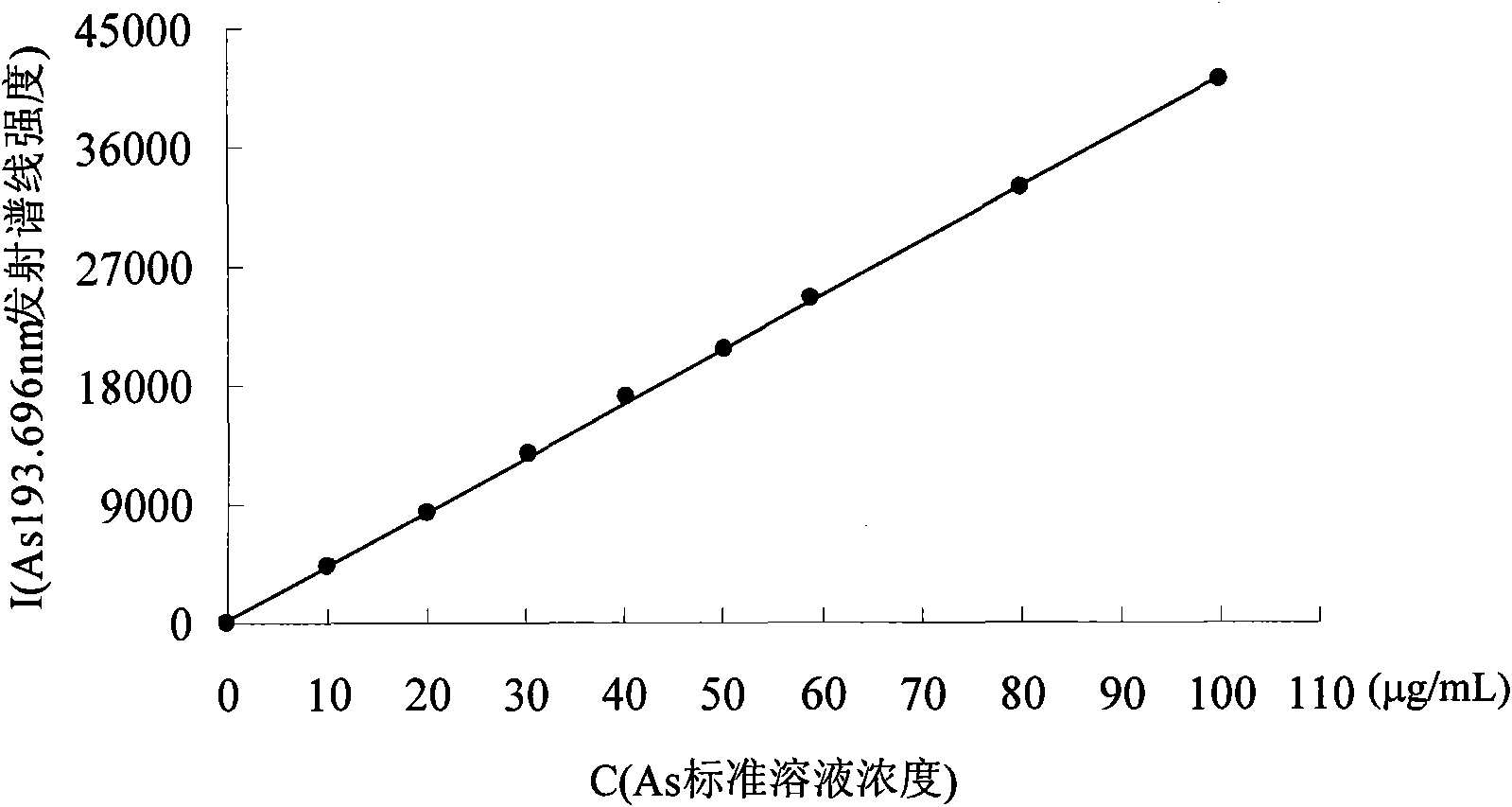

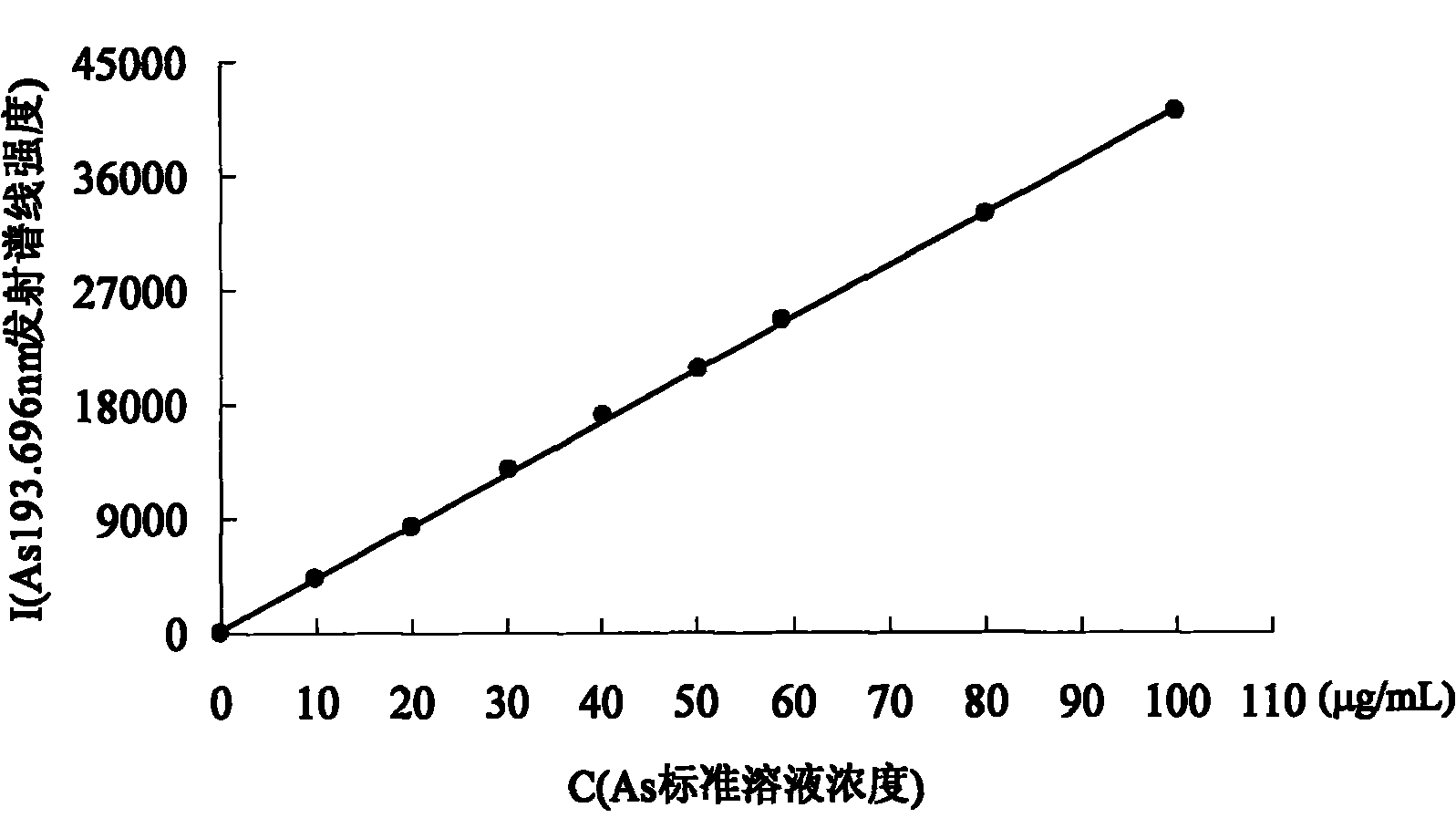

[0036] Analysis spectral line: The determination spectral line of As element is As193.696nm.

[0037] The concentration of arsenic single-element standard solution is 1mg / mL (GSB G 62028-90, National Iron and Steel Materials Testing Center Iron and Steel Research Institute); hydrochloric...

Embodiment 2

[0044] The determination procedure is the same as that in Example 1. The glass sample is selected from Zhejiang Zhenshen Thermal Insulation Technology Co., Ltd. The calculated mass percentage of total arsenic in the glass sample is 0.102%.

Embodiment 3

[0046] The determination steps are the same as in Example 1, the glass sample is selected from NBS standard reference material 89, and the calculated mass percentage of total arsenic in the glass sample is 0.347%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com