Low energy consumption flue gas wet desulphurization process

A wet desulfurization and low energy consumption technology, applied in the field of flue gas desulfurization, can solve the problems of difficult to popularize and use in a large area, increase water consumption, large water consumption, etc., achieve significant energy saving effect and reduce water consumption. , the effect of saving steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

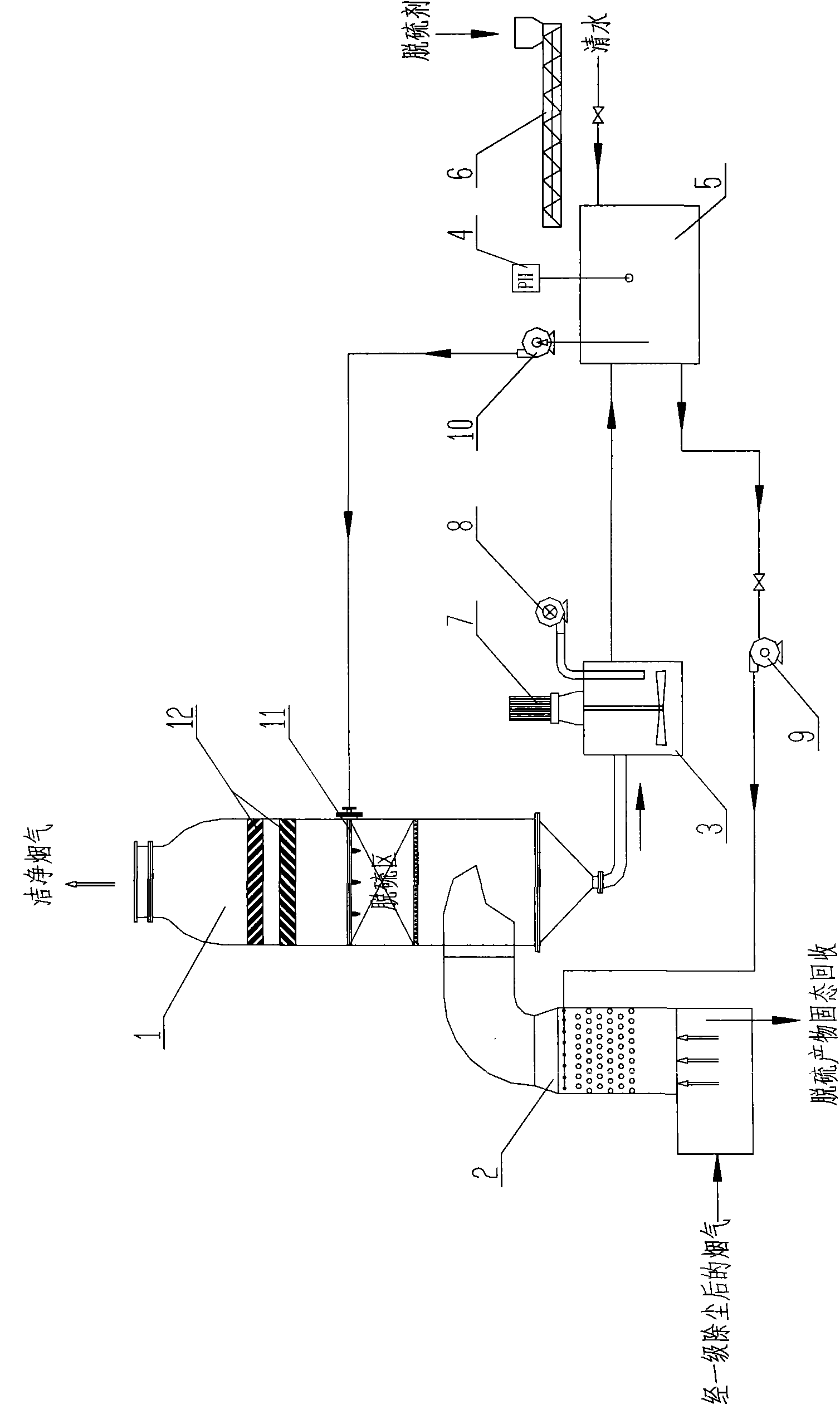

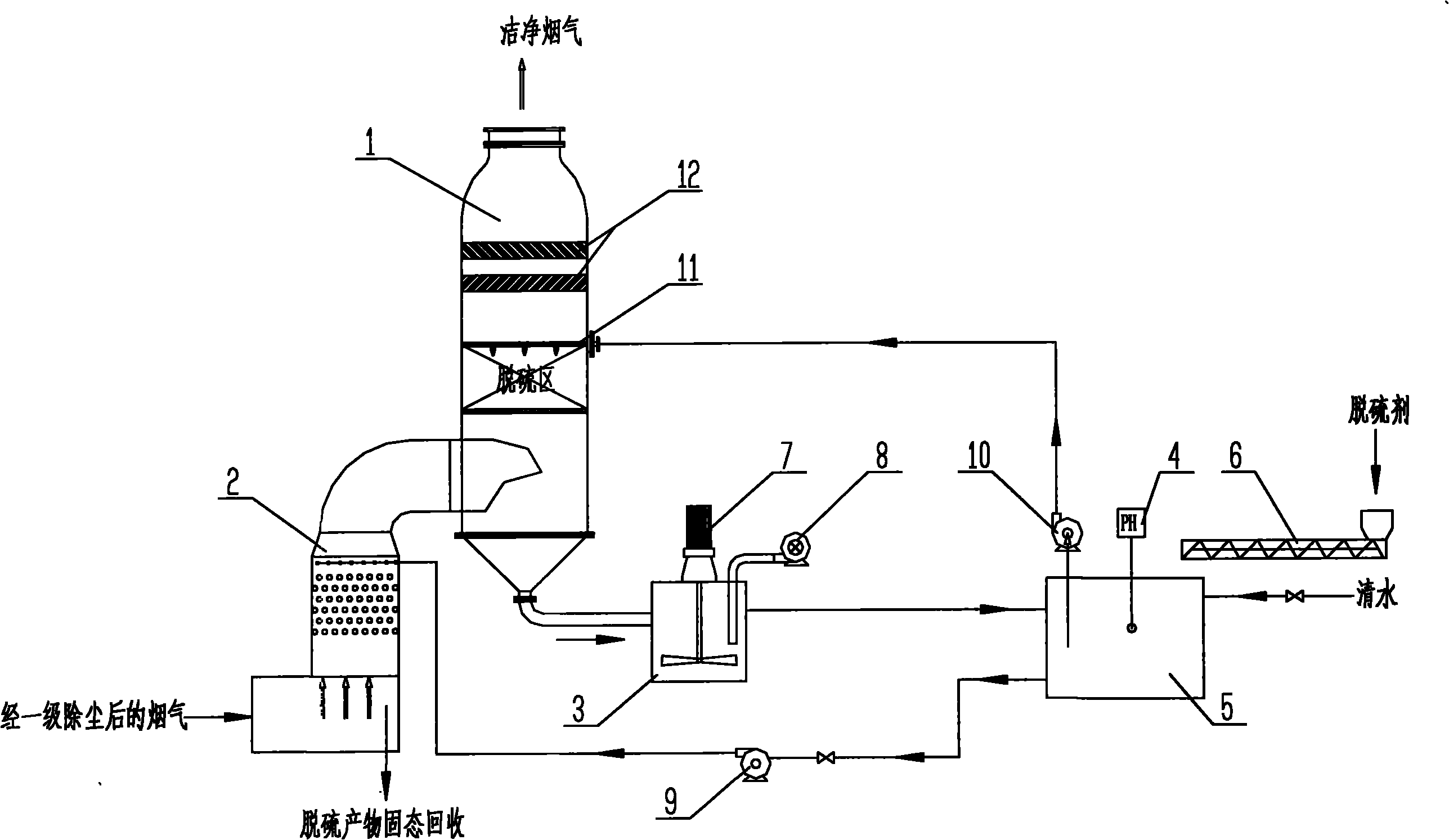

[0019] Below with limestone as desulfurizer, illustrate the implementation process of technique of the present invention, its concrete technological process is as follows figure 1 As shown, the flue gas that has undergone a dust removal process enters the desulfurization tower 1 through the flue gas evaporation crystallizer 2, and from the bottom of the desulfurization tower 1, the circulating water tank 5 uses a screw conveyor 6 to input limestone powder and forms a suitable slurry. It is equipped with a pH detector 4, and through the desulfurization circulation pump 10, the washing liquid containing alkaline absorbent is evenly sprayed from the spray layer 11, and the two are mixed in the desulfurization area, and the sulfur dioxide in the flue gas reacts with the alkaline absorbent , the flue gas from which sulfur dioxide has been removed passes through the demister 12 at the top of the desulfurization tower 1 to remove the liquid water therein, and then the clean flue gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com