Adhesive composition, adhesive layer, and adhesive sheet

An adhesive layer and adhesive technology, applied in the directions of non-polymer adhesive additives, adhesive types, adhesive additives, etc., can solve the problems of cumbersome, inability to use universal solvents, etc., to enhance mechanical properties , the effect of excellent refractive index and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

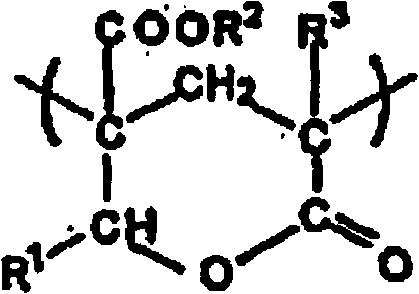

Method used

Image

Examples

preparation example Construction

[0044] For the preparation of such a (meth)acrylic polymer, known production methods such as solution polymerization, bulk polymerization, emulsion polymerization, and various radical polymerizations can be appropriately selected. In addition, the obtained (meth)acrylic polymer may be any of a random copolymer, a block copolymer, a graft copolymer, and the like.

[0045] Moreover, in solution polymerization, ethyl acetate, toluene, etc. are used as a polymerization solvent, for example. As a specific example of solution polymerization, a polymerization initiator is added under an inert gas flow such as nitrogen, and the reaction is usually carried out at about 50 to 70° C. for about 5 to 30 hours.

[0046] The polymerization initiator, chain transfer agent, emulsifier, etc. used for the radical polymerization are not particularly limited, and may be appropriately selected and used. In addition, the weight average molecular weight of a (meth)acryl-type polymer can be controlle...

Embodiment 1

[0168] (Preparation of Acrylic Polymer)

[0169] 99.5 parts by weight of n-butyl acrylate, 0.5 parts by weight of 4-hydroxybutyl acrylate, 0.1 parts by weight of 2,2'-azobisisobutyronitrile as a polymerization initiator and 200 parts by weight of ethyl acetate were put into the equipment Into the four-necked flask with stirring blade, thermometer, nitrogen gas introduction pipe and cooler, introduce nitrogen gas while stirring slowly, replace with nitrogen gas for 1 hour, then keep the liquid temperature in the flask at around 55°C, and carry out polymerization reaction for 15 hours to prepare An acrylic polymer solution with a weight average molecular weight of 1,800,000 was produced. The glass transition temperature of the obtained polymer was 219K.

[0170] Next, 10 parts by weight of a silicone compound (KR-9706 manufactured by Shin-Etsu Chemical Co., Ltd.) was added to 100 parts by weight of titanium dioxide (TTO-51C manufactured by Ishihara Sangyo), and 330 parts by wei...

Embodiment 2

[0173] (Preparation of Acrylic Polymer)

[0174] The acrylic polymer solution obtained in Example 1 is diluted to 25% with ethyl acetate, 50 parts by weight of styrene and 0.2 parts by weight of benzoyl peroxide are added in the solution of 400 parts by weight, and the In the four-necked flask of the tube and the cooling tube, after the nitrogen gas was fully replaced, the polymerization reaction was carried out at 65° C. for 6 hours and at 70° C. for 6 hours while stirring under a nitrogen gas flow to obtain a graft polymer. The glass transition temperature of the graft portion of this polymer was 373K.

[0175] With respect to the solid content of 100 parts by weight of the polymer, in the obtained graft polymer solution, 10 parts by weight of the same titanium dioxide dispersion as in Example 1 and 80 parts by weight of styrene low-molecular-weight polymer solution dissolved in toluene were added in terms of solid content. (SX-85 manufactured by YASUHARA CHEMICAL Co., Ltd....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com