Quantum dot optical fiber core material with PMMA as substrate and preparation and application thereof

An optical fiber core and quantum dot technology, applied in the field of optical fiber core materials, can solve problems such as no one reported, and achieve the effects of preventing agglomeration, high mechanical strength, and high optical gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]A mixture of 25ml of methyl methacrylate (MMA) and 0.25g of azobisisobutyronitrile (AIBN) was pre-polymerized at 75°C for 15 minutes, and quenched in water. Then put it into a constant temperature drying oven to polymerize for 16 hours at a temperature of 50° C. to obtain a PMMA colloid.

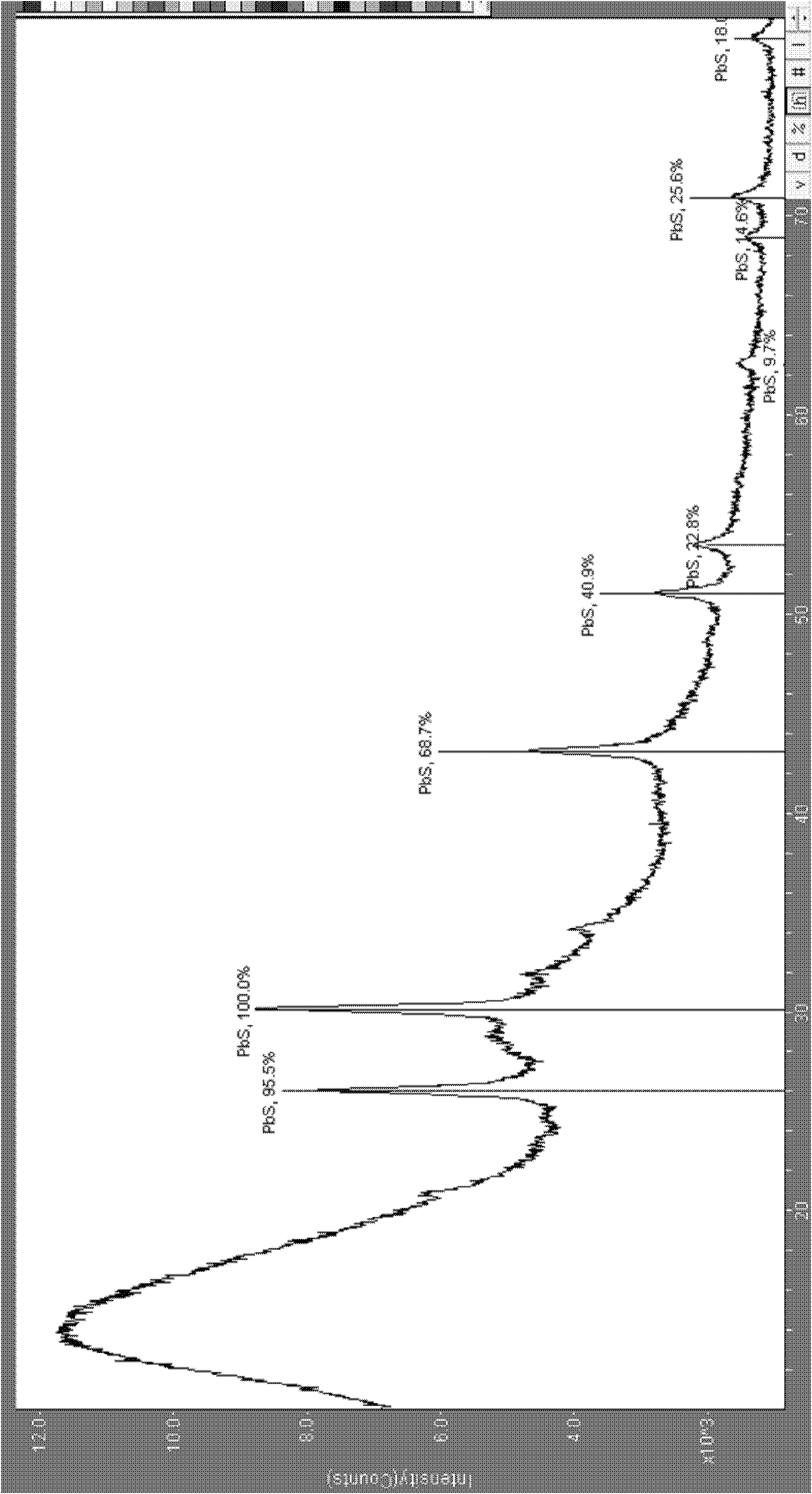

[0029] Add 3ml, 0.02mol / L sodium sulfide and lead nitrate solution into 50ml, 0.2mol / L aerosol n-heptane solution, stir well to form sodium sulfide reverse gel solution and lead nitrate reverse gel solution respectively ; In the case of strong stirring, slowly add the sodium sulfide reverse gel solution to the lead nitrate reverse gel solution, the solution will change from a transparent liquid to a reddish-brown liquid. Centrifuge the obtained reddish-brown liquid in a centrifuge for 5-15 minutes. At this time, the solution will appear precipitated and layered. The precipitate is PbS quantum dots, and the obtained precipitate is centrifugally washed with distilled water for 3 times, a...

Embodiment 2

[0033] A mixture of 25ml of methyl methacrylate (MMA) and 0.25g of azobisisobutyronitrile (AIBN) was pre-polymerized at 90°C for 7 minutes, and quenched in water. Then put it into a constant temperature drying oven to polymerize for 4 hours at a temperature of 50° C. to obtain a PMMA colloid.

[0034] Add 1ml, 0.02mol / L sodium sulfide and lead nitrate solution to 50ml, 0.2mol / L aerosol n-heptane solution respectively, stir well to form sodium sulfide reverse gel solution and lead nitrate reverse gel solution; In the case of strong stirring, slowly add the sodium sulfide reverse gel solution into the lead nitrate reverse gel solution, and the solution will change from a transparent liquid to a reddish-brown liquid. Centrifuge the obtained reddish-brown liquid in a centrifuge for 5-15 minutes. At this time, the solution will appear precipitated and layered. The precipitate is PbS quantum dots, and the obtained precipitate is centrifugally washed with distilled water for 3 times,...

Embodiment 3

[0038] A mixture of 25ml of methyl methacrylate (MMA) and 0.25g of azobisisobutyronitrile (AIBN) was pre-polymerized at 75°C for 10 minutes and cooled at room temperature. Then put it into a constant temperature drying oven to polymerize for 24 hours at a temperature of 50°C to obtain a PMMA colloid.

[0039] Add 1.5ml, 0.01mol / L sodium sulfide and lead nitrate solution to 50ml, 0.1mol / L aerosol n-heptane solution, stir well to form sodium sulfide reverse gel solution and lead nitrate reverse gel solution ; In the case of strong stirring, slowly add the sodium sulfide reverse gel solution to the lead nitrate reverse gel solution, the solution will change from a transparent liquid to a reddish-brown liquid. Centrifuge the obtained reddish-brown liquid in a centrifuge for 5-15 minutes. At this time, the solution will appear precipitated and layered. The precipitate is PbS quantum dots, and the obtained precipitate is centrifugally washed with distilled water for 3 times, and fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com