Smoke processing technology

A flue gas treatment and process technology, applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high cost of flue gas treatment, serious pollution, and low processing efficiency, and achieve resource consumption and process saving , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

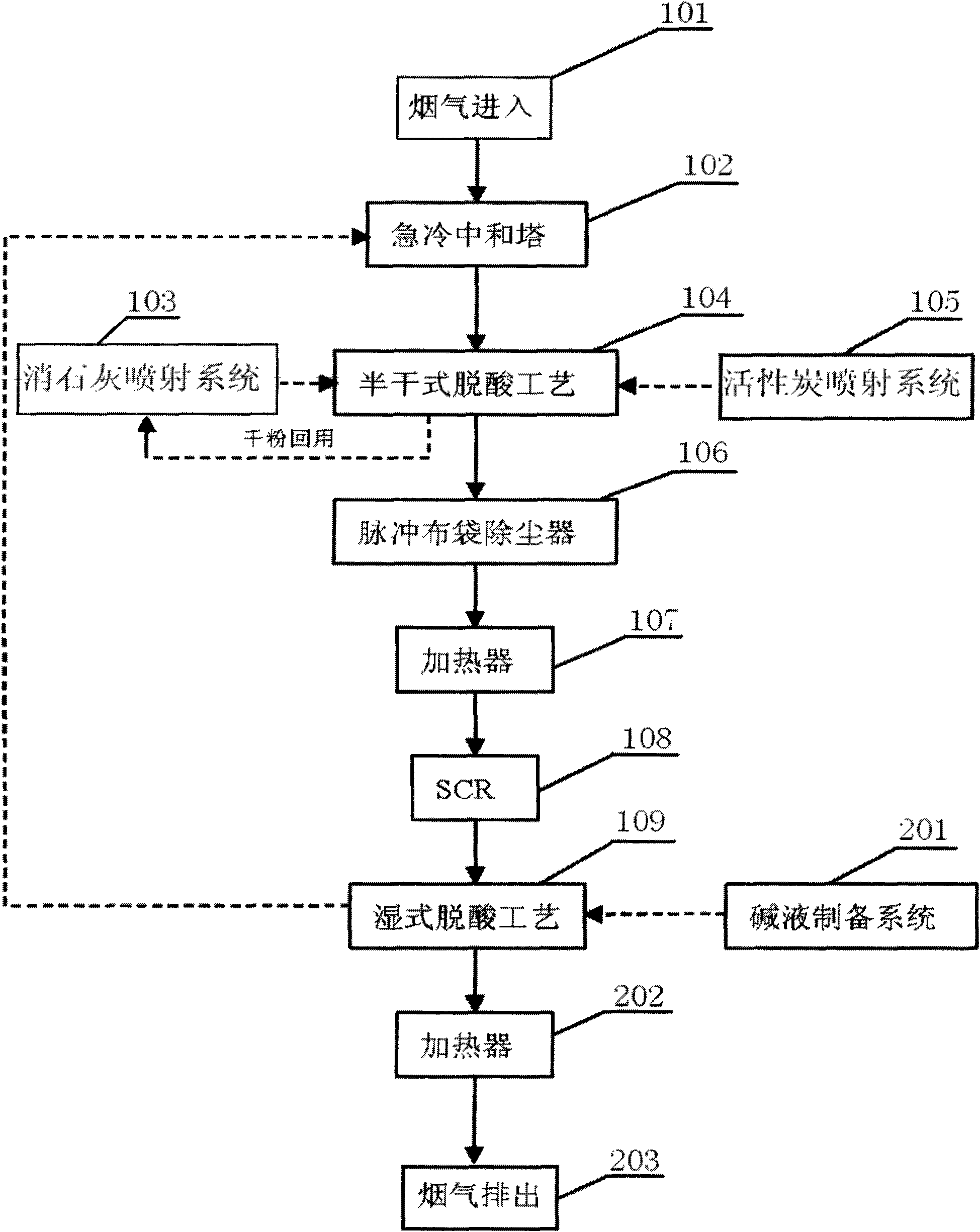

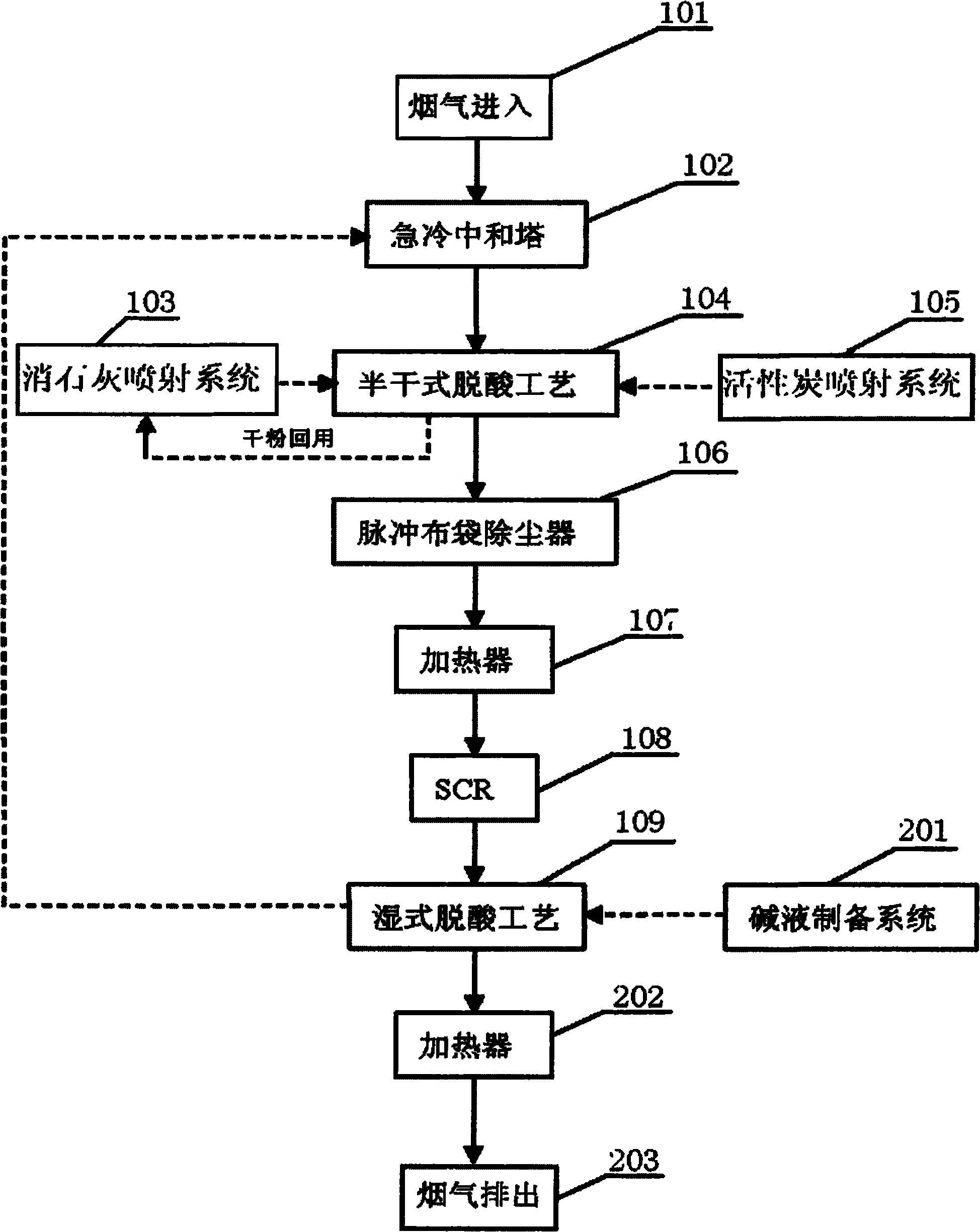

[0021] see figure 1 , the solid arrows in the figure represent the main process line; the dotted arrows represent the drug flow line. The present invention mainly is divided into following six technical processes:

[0022] (1) Rapid cooling and cooling:

[0023] First, after the flue gas enters the process of 101, the flue gas enters the quenching neutralization tower 102, and the quenching neutralization tower 102 uses the evaporation of sprayed water in the high-temperature airflow to achieve the purpose of cooling the airflow, reducing the temperature of the furnace gas from 500-600°C to Below 200°C. In order to rapidly cool the high-temperature airflow, it is first necessary to ensure that the airflow is evenly distributed in the cooler, especially the dusty airflow. For this reason, the present invention adopts unique intake distribution device.

[0024] The water spray gun is designed to be made of high-grade stainless steel with high temperature resistance, wear res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com