Preparation method of copper indium selenide nanocrystalline material

A nanocrystalline material, copper indium selenide technology, applied in chemical instruments and methods, selenium/tellurium compounds, inorganic chemistry, etc., can solve the problems of poor optimization of devices and low energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

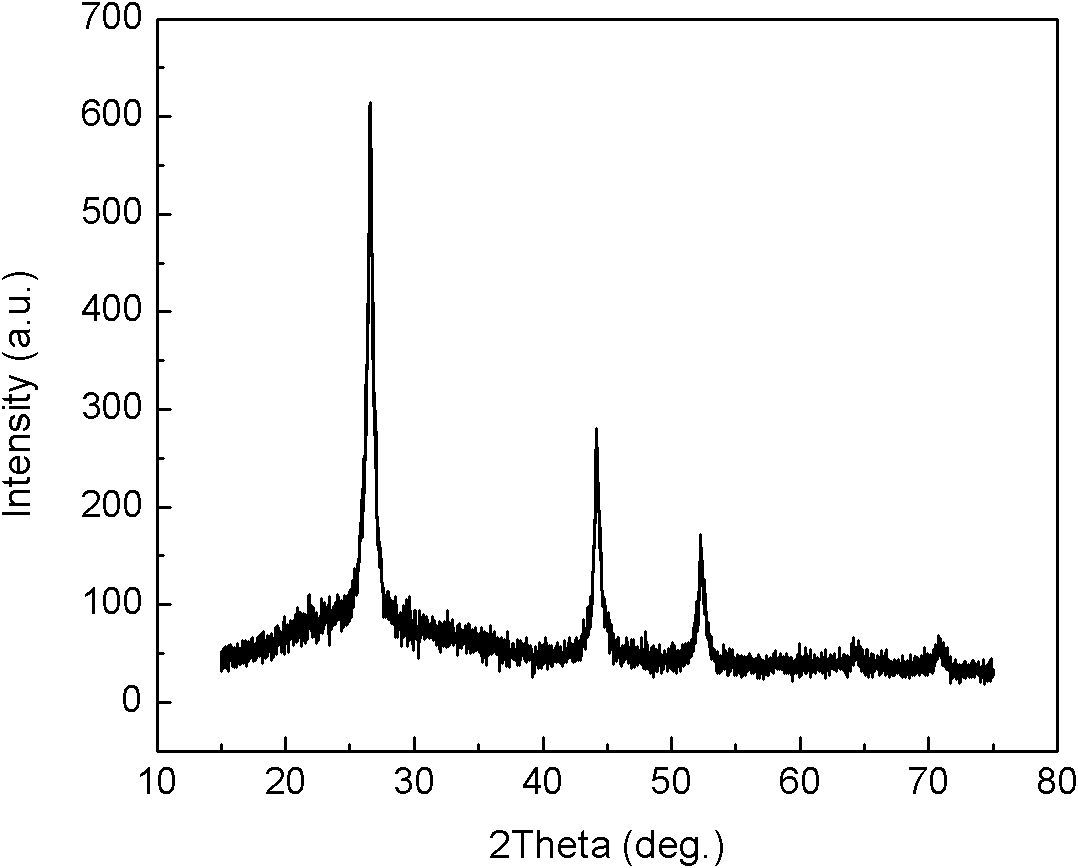

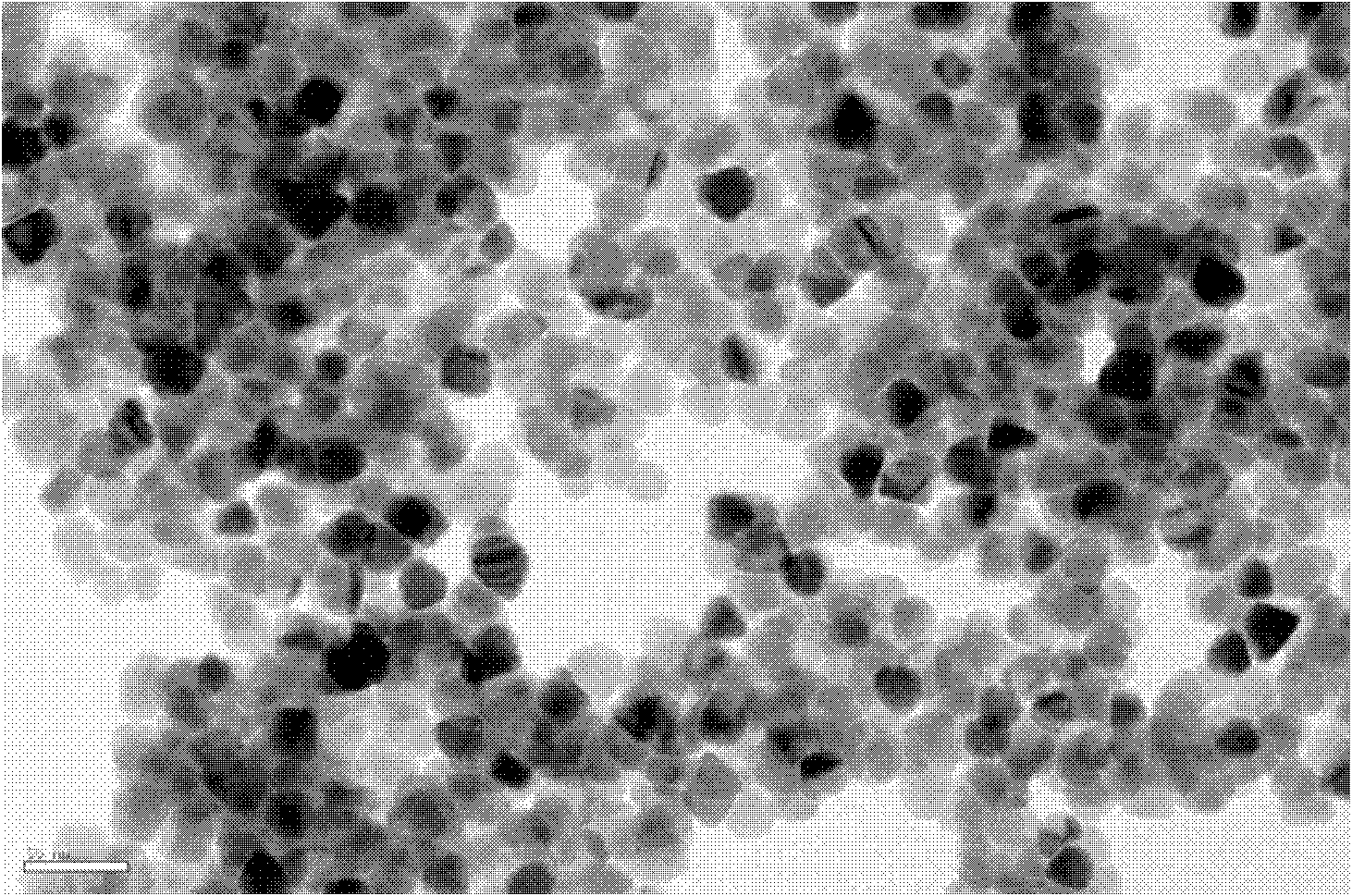

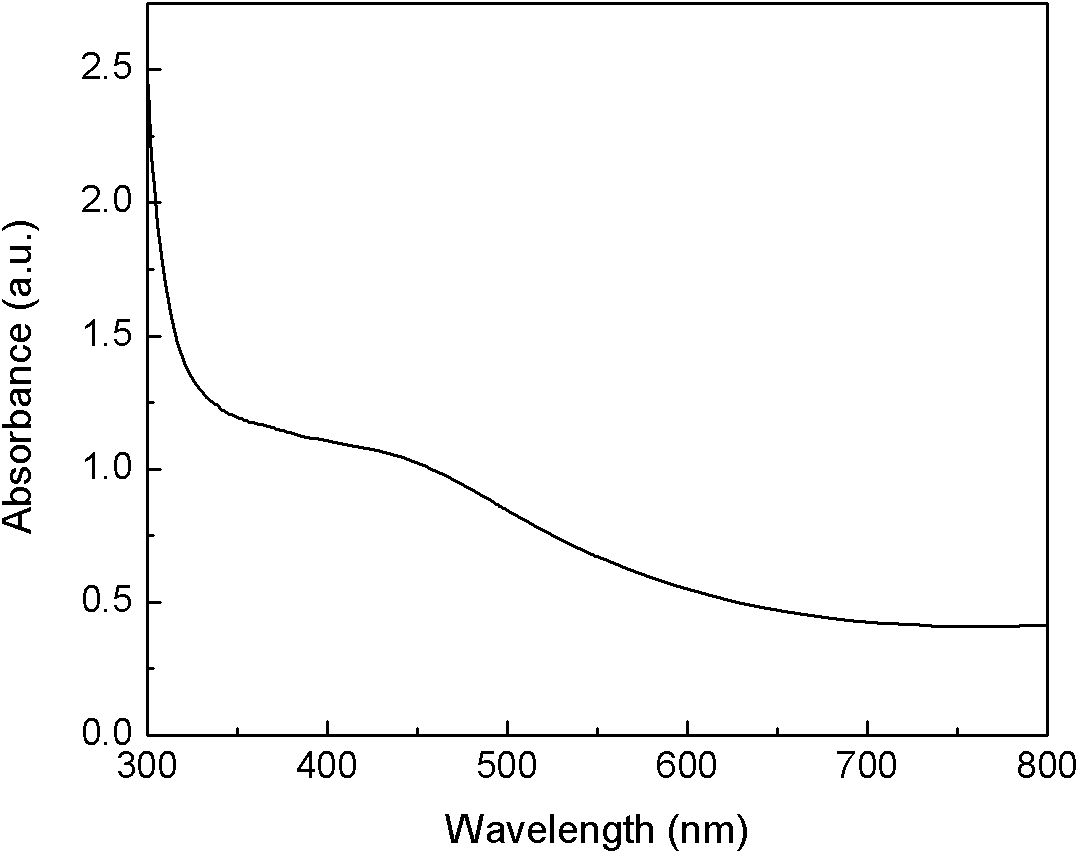

Image

Examples

Embodiment 1

[0009] Embodiment 1: 1) at first, the copper chloride of 0.5 millimole, the indium chloride of 0.5 millimole, the selenium powder of 1 millimole are added in the oleylamine of 10 milliliters to obtain mixed solution, then this mixed solution is heated to Insulate at 60°C for 3 hours, while vigorously stirring with nitrogen gas; 2) Next, heat the mixed solution obtained in step 1) to 240°C, while passing nitrogen gas, and condensing and refluxing, vigorously stirring, and reacting for 4 hours; 3) Then, Add 10 ml of ethanol to the solution in step 2) and centrifuge at a speed of 5000 rpm for 5 minutes, remove the supernatant to obtain a precipitate; 4) add 5 ml of chloroform and 10 ml of ethanol to the precipitate, and ultrasonically dissolve the precipitate and mix well , centrifuge at a speed of 5000rpm for 5 minutes, remove the supernatant to obtain a precipitate, then add 5 ml of chloroform and 10 ml of ethanol to the precipitate and repeat 3 times; 5) Finally, add 5 ml of ch...

Embodiment 2

[0010] Embodiment 2: 1) at first, the selenium powder of the cuprous chloride of 1 mmol, the indium chloride of 1 mmol, the selenium powder of 2 mmol are added in the oleylamine of 12 milliliters to obtain mixed solution, then this mixed solution is heated Keep warm at 80°C for 2 hours, while stirring vigorously with nitrogen gas; 2) Next, heat the mixed solution obtained in step 1) to 210°C, while passing nitrogen gas, and condense and reflux, stir vigorously, and react for 4 hours; 3) Then , add 15 milliliters of ethanol to the solution in step 2) and centrifuge at a speed of 6000 rpm for 4 minutes, remove the supernatant to obtain a precipitate; 4) add 10 milliliters of chloroform and 20 milliliters of ethanol to the precipitate, and ultrasonically dissolve and mix the precipitate Evenly, centrifuge at a speed of 6000rpm for 4 minutes, remove the supernatant to obtain a precipitate, then add 10 ml of chloroform and 20 ml of ethanol to the precipitate and repeat 3 times; 5) F...

Embodiment 3

[0011] Embodiment 3: 1) at first, the copper chloride of 1.5 millimoles, the indium chloride of 1.5 millimoles, the selenium powder of 3 millimoles are added in the oleylamine of 8 milliliters to obtain mixed solution, then this mixed solution is heated to Insulate at 65°C for 2.5 hours, while stirring vigorously with nitrogen gas; 2) Next, heat the mixed solution obtained in step 1) to 230°C, while passing nitrogen gas, and condense and reflux, stir vigorously, and react for 2 hours; 3) Then, Add 20 milliliters of ethanol to the solution in step 2) and centrifuge at a speed of 8000 rpm for 3 minutes, remove the supernatant to obtain a precipitate; 4) add 8 milliliters of chloroform and 16 milliliters of ethanol to the precipitate, and ultrasonically dissolve the precipitate and mix well , centrifuged at a speed of 8000rpm for 3 minutes, removed the supernatant to obtain a precipitate, then added 8 ml of chloroform and 16 ml of ethanol to the precipitate and repeated 3 times; 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com