Film-coating liquid of vanadium dioxide thin film and preparation method and application of thin film

A technology of vanadium dioxide and coating solution, which is applied in the preparation of vanadium dioxide thin film, in the field of preparing vanadium dioxide thin film with high visible light transmittance and infrared intelligent control ability, which can solve the problem of low infrared control performance and visible light transmission. Low efficiency, high production cost and other problems, to achieve the effect of simple equipment requirements, high visible light transmittance, and good film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

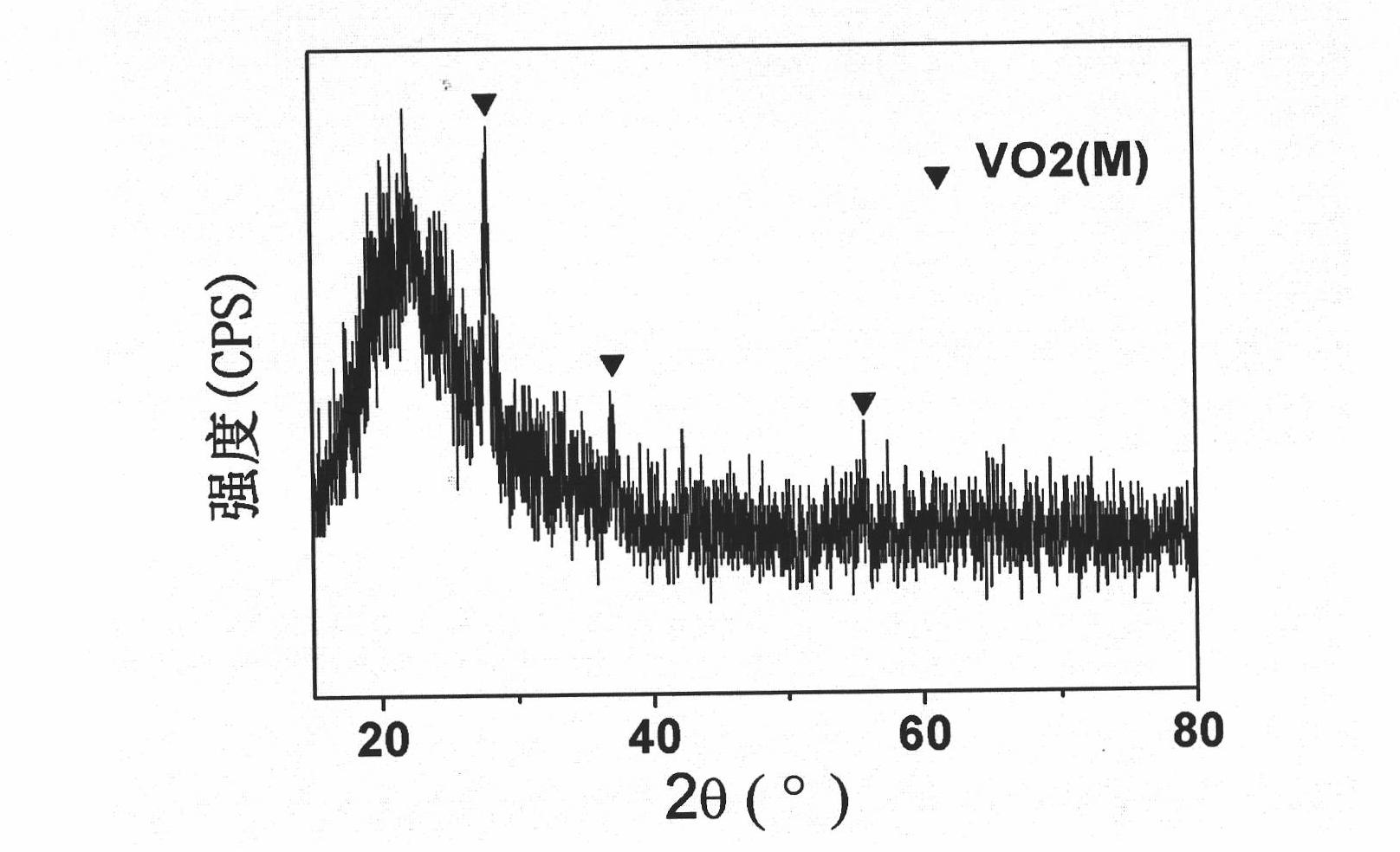

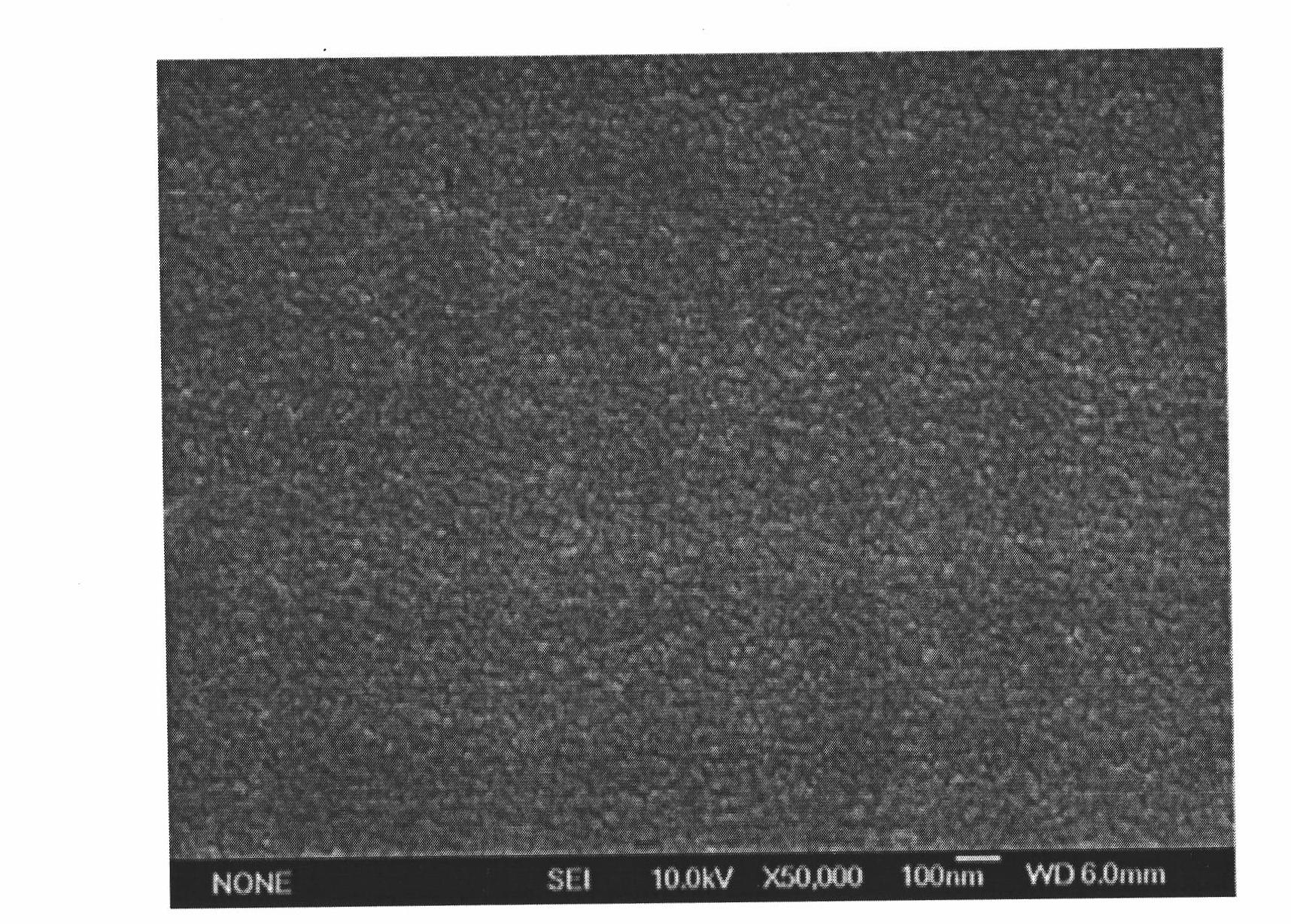

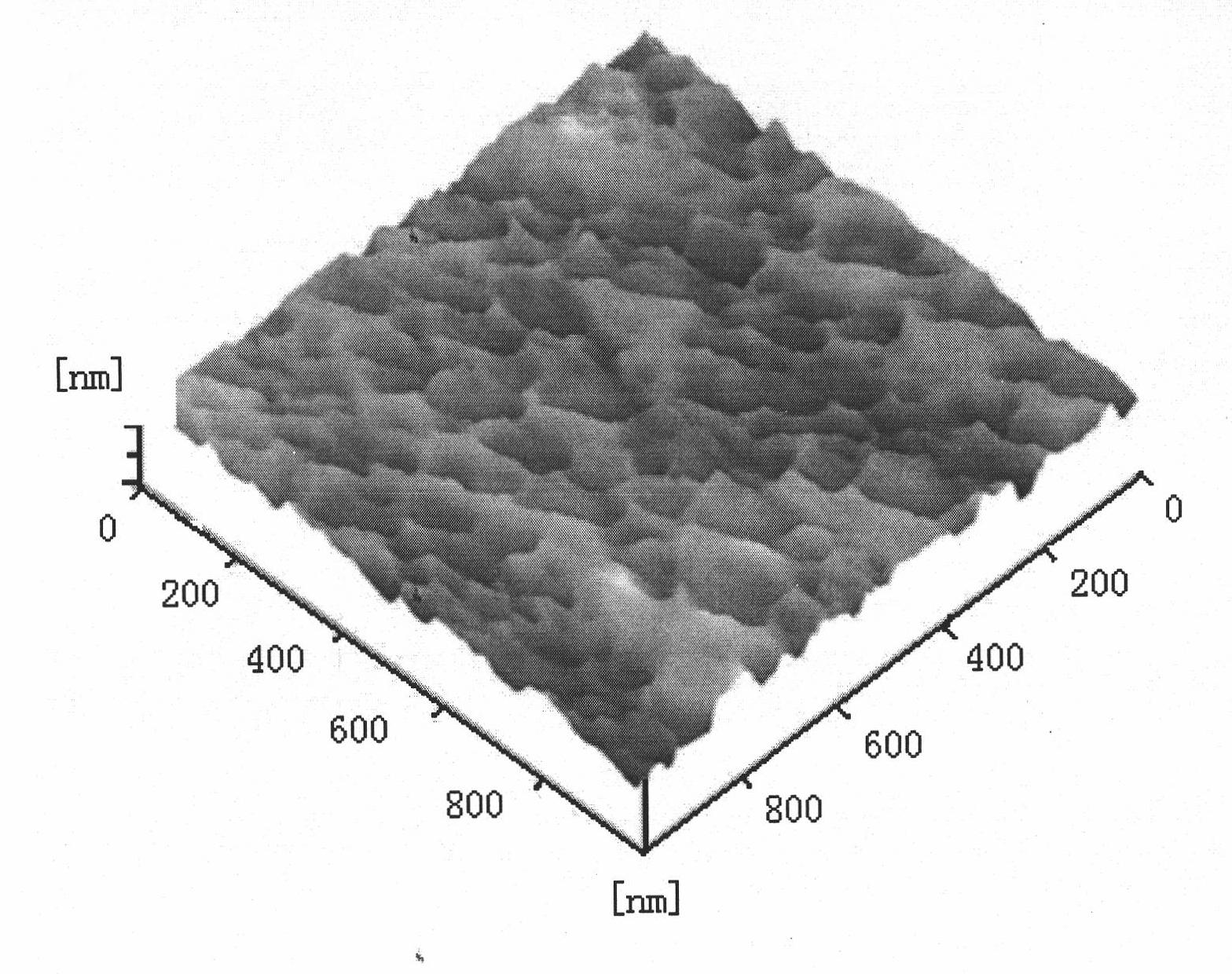

[0054] Preparation of undoped vanadium dioxide thin films

[0055] (1) Preparation of coating solution:

[0056] Take 1g of vanadyl acetylacetonate (molar concentration is 0.06Mol / L), after simple grinding, put the obtained powder into a 100ml beaker, add 40ml of a mixed solution of methanol, alcohol and propanol, wherein the volume of methanol, alcohol and n-propanol The ratio is 2:1:2, put into a magnetic stirrer and stir. Add a total of 20ml of mixed additives of oleic acid, ethylene glycol and glycerin (the mass percentage of mixed additives is 40%), wherein the volume ratio of oleic acid, ethylene glycol and glycerin is 1:1:2, stir and age for one week A coating solution for the vanadium dioxide thin film is obtained.

[0057] (2) Clean the substrate:

[0058] Select the substrate as quartz glass, and use the standard RCA process to clean it to remove organic matter, dust and metal ion impurities on the surface. Afterwards, the substrate was dried in an oven at 60°C f...

Embodiment 2

[0073] Vanadium dioxide thin film doped with 3 mole percent tungsten

[0074] (1) Preparation of coating solution:

[0075] Take 10g of vanadyl acetylacetonate and 0.28g of tungstic acid. After simple grinding, put the resulting powder into a 500ml beaker, add 200ml of a mixed solution of methanol, alcohol and propanol, wherein the volume ratio of methanol, alcohol and propanol is 2: 1:2, placed in a magnetic stirrer and stirred. Add a total of 0.2ml of mixed additives of oleic acid and hydrochloric acid (the mass percentage of mixed additives is 0.1%), wherein the volume ratio of oleic acid and hydrochloric acid is 1:1, stir and age to obtain doped vanadium dioxide Thin film coating solution.

[0076] (2) Clean the substrate:

[0077] Select the substrate as quartz glass, and use the standard RCA process to clean it to remove organic matter, dust and metal ion impurities on the surface. After that, put the substrate into a 60°C oven for drying treatment before use.

[00...

Embodiment 3

[0083] Preparation of vanadium dioxide thin film doped with 0.07% tungsten by mole

[0084] (1) Preparation of coating solution:

[0085] Take 10g of vanadyl acetylacetonate and 0.0066g of tungstic acid, after simple grinding, put the obtained powder into a 100ml beaker, add 250ml of a mixed solution of methanol and n-propanol, wherein the volume ratio of methanol and n-propanol is 2:1, put Stir in a magnetic stirrer. Add a total of 20ml of mixed additives of oleic acid, hydrofluoric acid and hydrogen peroxide (the mass percentage of mixed additives is 16%), wherein the volume ratio of oleic acid, hydrofluoric acid and hydrogen peroxide is 5:1:1. After stirring and aging for one week, the coating solution of the vanadium dioxide thin film was obtained.

[0086] (2) Clean the substrate:

[0087] Select the substrate as quartz glass, and use the standard RCA process to clean it to remove organic matter, dust and metal ion impurities on the surface. Afterwards, the substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com