Method for preparing waterborne polyurethane/organosilicon montmorillonite nano composite material

A technology of water-based polyurethane and organic montmorillonite, applied in polyurea/polyurethane coatings, dyed organic silicon compound treatment, fibrous fillers, etc., can solve the problems of water-based polyurethane limitations, etc., and achieve good compatibility, convenient operation and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

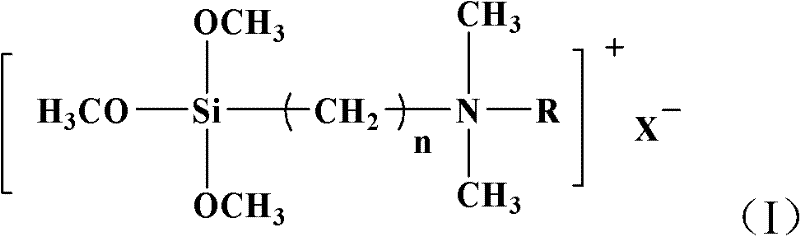

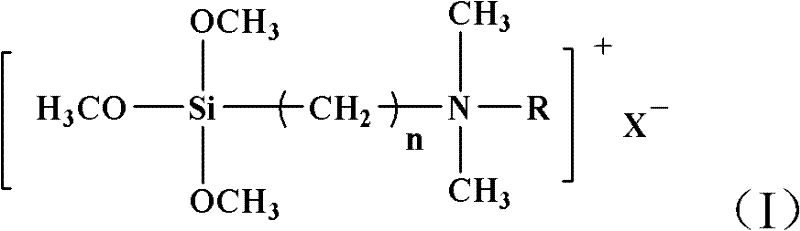

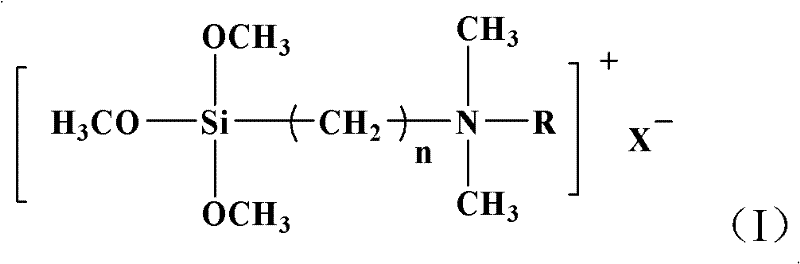

[0054] (1) Organizing montmorillonite with 3-(trimethoxysilyl)propyldimethyloctadecylammonium chloride

[0055] Dissolve 10 g of sodium montmorillonite Na-MMT in 90 g of distilled water, add 5 g of 3-(trimethoxysilyl) propyl dimethyl octadecyl ammonium chloride, and 100 mL of ethanol aqueous solution (50%). The mixed solution was stirred at 20°C for 100 h, then filtered with suction, and washed with deionized water until 0.1 mol / L of AgNO 3 Solution detection filtrate without precipitation, vacuum dried to constant weight, ground, sieved to obtain 325 mesh organic montmorillonite.

[0056] (2) In the reaction device equipped with electric stirrer, heating device and temperature controller, add 90g of polyether N210 after vacuum dehydration and drying, 10g of 325 mesh organic montmorillonite obtained above, and heat at 80°C for 8h , and then shear 0.5h at a shear rate of 10000rpm with a high-speed shearing machine to prepare the organic montmorillonite of polyether N210 pre-in...

Embodiment 2

[0060] (1) Organizing montmorillonite with 3-(trimethoxysilyl)propyldimethylhexadecylammonium bromide

[0061] Dissolve 10 g of potassium-based montmorillonite Ka-MMT in 990 g of distilled water, add 5 g of 3-(trimethoxysilyl) propyl dimethyl hexadecyl ammonium bromide, and 990 mL of ethanol aqueous solution (50%). The mixed solution was stirred at 90°C for 1 h, then filtered with suction, and washed with deionized water until 0.1 mol / L of AgNO 3 Solution detection filtrate without precipitation, vacuum dried to constant weight, ground, sieved to obtain 325 mesh organic montmorillonite.

[0062] (2) In the reaction device equipped with electric stirrer, heating device and temperature controller, add 70g of polyether N210 after vacuum dehydration and drying, 30g of 325 mesh organic montmorillonite obtained above, and heat at 130°C for 3h , and then shear 0.5h at a shear rate of 10000rpm with a high-speed shearing machine to prepare the organic montmorillonite of polyether N210...

Embodiment 3

[0066] (1) Organizing montmorillonite with 3-(trimethoxysilyl)propyldimethylpentyl ammonium chloride

[0067] Dissolve 10g of calcium-based montmorillonite Ca-MMT in 90g of distilled water, add 50g of 3-(trimethoxysilyl)propyldimethylpentylammonium chloride, and 100mL of ethanol aqueous solution (50%), and mix the above The solution was stirred at 80°C for 4 h, then filtered with suction, and washed with deionized water until 0.1 mol / L of AgNO 3 Solution detection filtrate without precipitation, vacuum dried to constant weight, ground, sieved to obtain 325 mesh organic montmorillonite.

[0068] (2) In the reaction device equipped with electric stirrer, heating device and temperature controller, add 90g of polyether N210 after vacuum dehydration and drying, 10g of 325 mesh organic montmorillonite obtained above, and heat at 90°C for 4h , and then sheared for 2 hours at a shear rate of 10,000 rpm with a high-speed shearing machine to prepare polyether N210 pre-intercalated orga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| cation exchange capacity (equivalent) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com