Supergravity hydrothermal preparation method of spherical inorganic powder grains

A technology of inorganic powder and supergravity, applied in the direction of inorganic chemistry, chemical instruments and methods, lead sulfide, etc., can solve the problem that it is difficult to prepare spherical powder, and achieve the effect of easy control of reaction and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

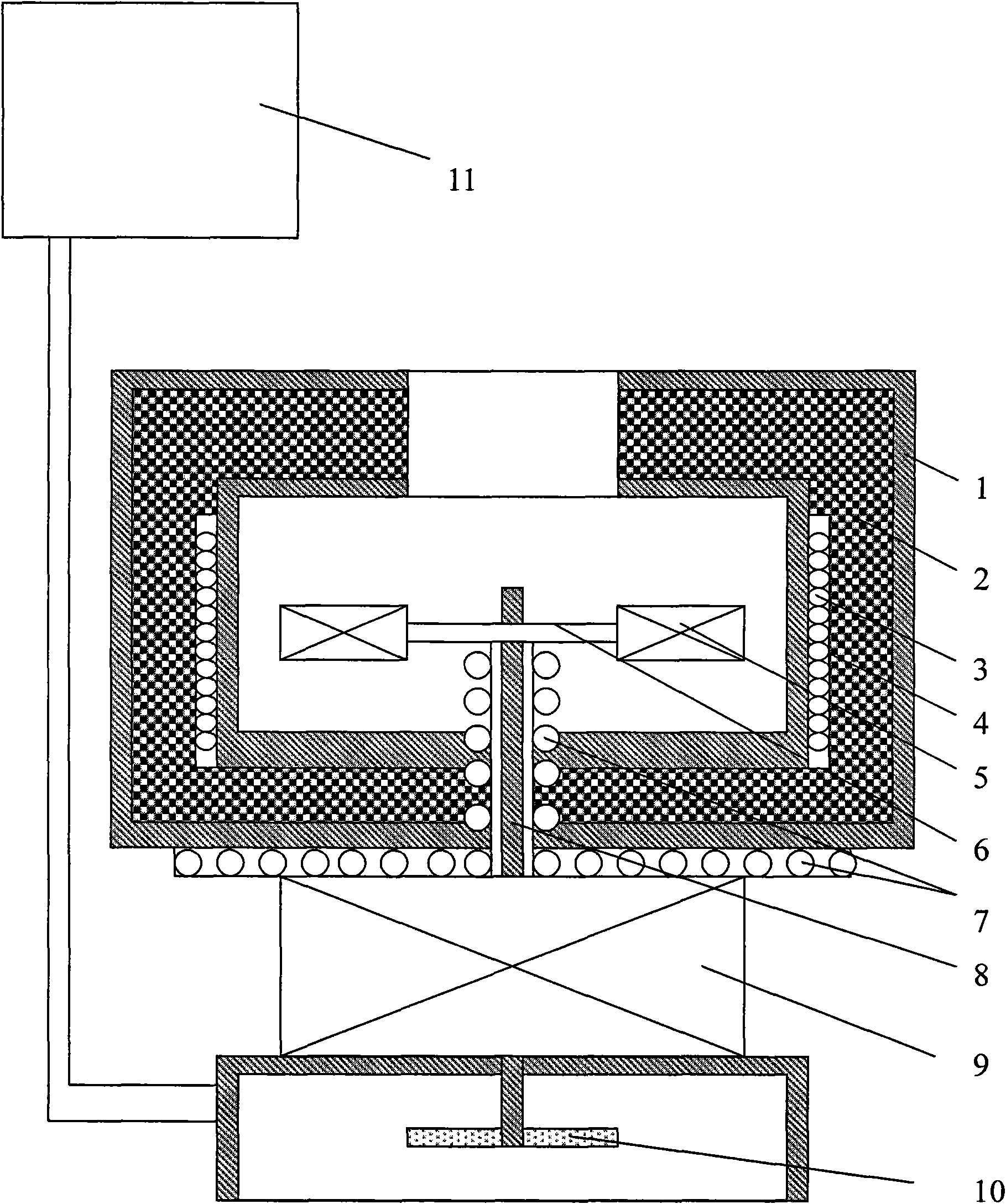

[0046] figure 1 It is a schematic diagram of the structure of a high-gravity hydrothermal reaction equipment, in which: 1. Furnace shell, 2 insulation bricks, 3 heating wire, 4 anti-riot cylinder, 5 autoclave, 6 fixed bracket, 7 cooling water pipe, 8 rotating shaft, 9 motor, 10 wind blades, 11 for

[0047] The structure of the equipment includes a centrifugal device, a high-pressure reaction kettle, and a temperature control furnace, wherein the centrifugal device includes a motor and a fixed bracket fixed on the motor shaft; the temperature control furnace includes a temperature controller, an electric heating wire, an insulation material and a furnace shell; the autoclave Including kettle lid, kettle body and PTFE lining. The fixed bracket of the centrifugal device is located in the cavity of the temperature control furnace, and the high-pressure reaction kettle is installed on the fixed bracket of the centrifugal device.

Embodiment 2

[0049] The preparation of spherical cadmium sulfide particle powder: its preparation steps are:

[0050] Step 1: Add a certain amount of cadmium chloride to 5 ml of deionized water to prepare a cadmium chloride solution with a concentration of 0.1-1mol / l;

[0051] Step 2: add a certain amount of thioacetamide in the solution of step 1, adjust the pH value to make it dissolve, and require the molar ratio of cadmium chloride and sodium thiosulfate to be 1:2;

[0052] Step 3: add 2 milliliters of bromobenzene in the solution of step 2;

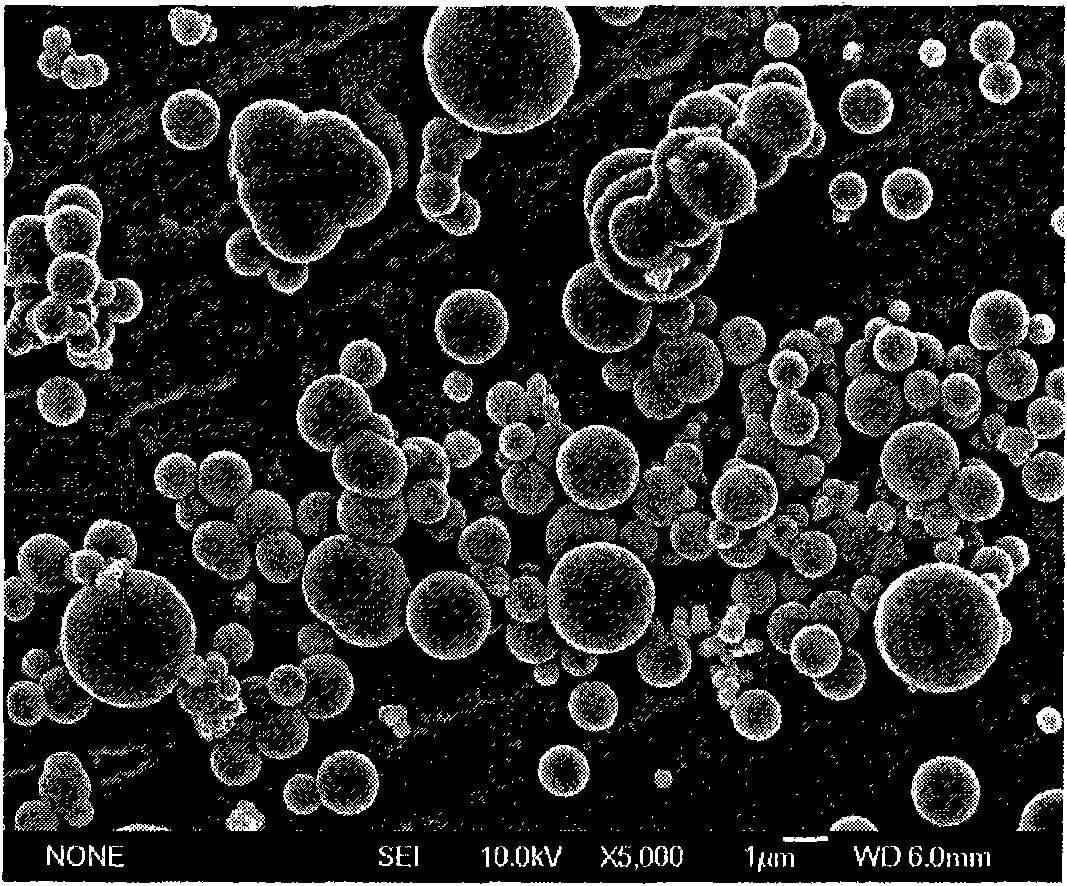

[0053] Step 4: Put the mixed solution in step 3 into the autoclave, seal the autoclave, and fix it on figure 1 on a fixed stand in the hypergravity reaction apparatus shown. Then make the relative centrifugal force be 1000 grams, heat up to 120-150 ℃, keep warm for half an hour, and cool down. The product was taken out, washed repeatedly with carbon disulfide, ethanol and distilled water, and then dried in vacuum at 80° C. for 1 h. The morpho...

Embodiment 3

[0055] Preparation of spherical zinc sulfide particle powder: its preparation steps are:

[0056] Step 1: adding a certain amount of zinc chloride to 5 ml of deionized water to form a zinc chloride solution with a concentration of 0.1-1mol / l;

[0057] Step 2: Add a certain amount of sodium thiosulfate to the solution in step 1, adjust the pH value to dissolve it, and require the mol ratio of zinc chloride and thiocaproamide to be 1:1;

[0058] Step 3: Add 1.5 milliliters of o-dichlorobenzene to the solution in step 2;

[0059] Step 4: Put the mixed solution in step 3 into the autoclave, seal the autoclave, and fix it on figure 1 on a fixed stand in the hypergravity reaction apparatus shown. Then make the relative centrifugal force be 1500 grams, heat up to 120-150 ℃, keep warm for half an hour, and cool down.

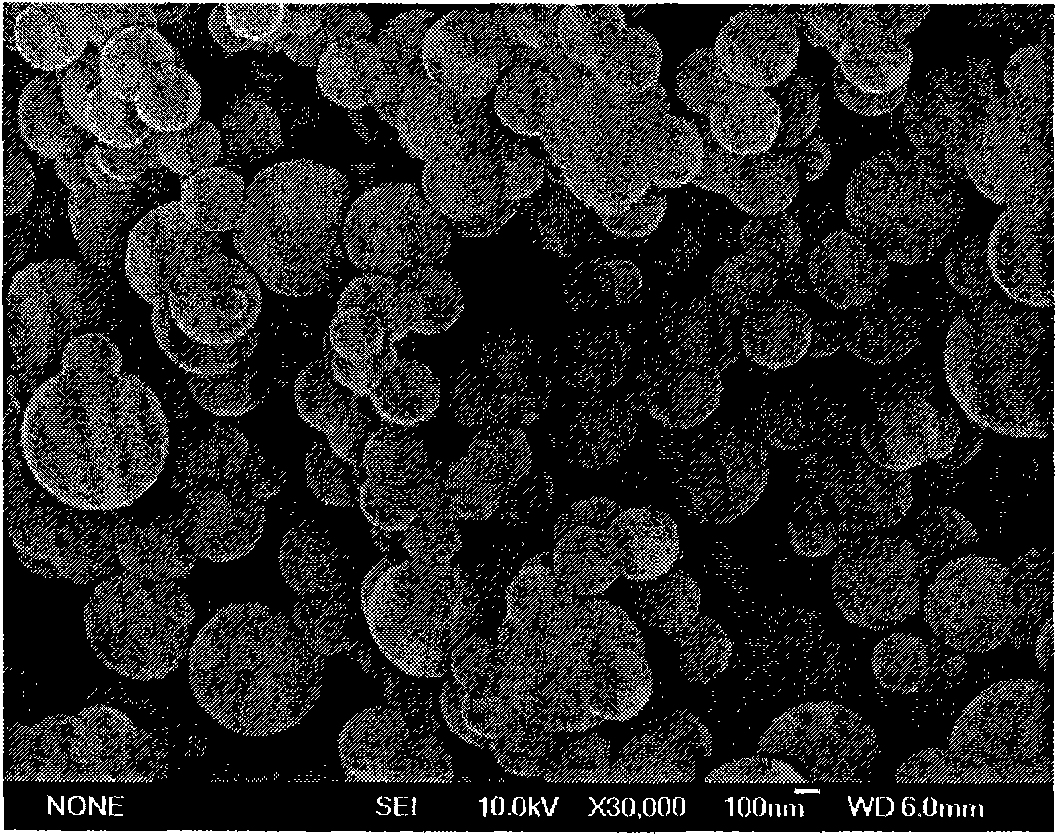

[0060] The product was taken out, washed repeatedly with carbon disulfide, ethanol and distilled water, and then dried in vacuum at 80° C. for 2 h. The morphology o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com