Green fuel oil and preparation method thereof

A kind of fuel oil and green technology, applied in the field of green fuel oil and its preparation, can solve the problems of high oxygen content, difficult continuous production, high corrosion, etc., and achieve the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

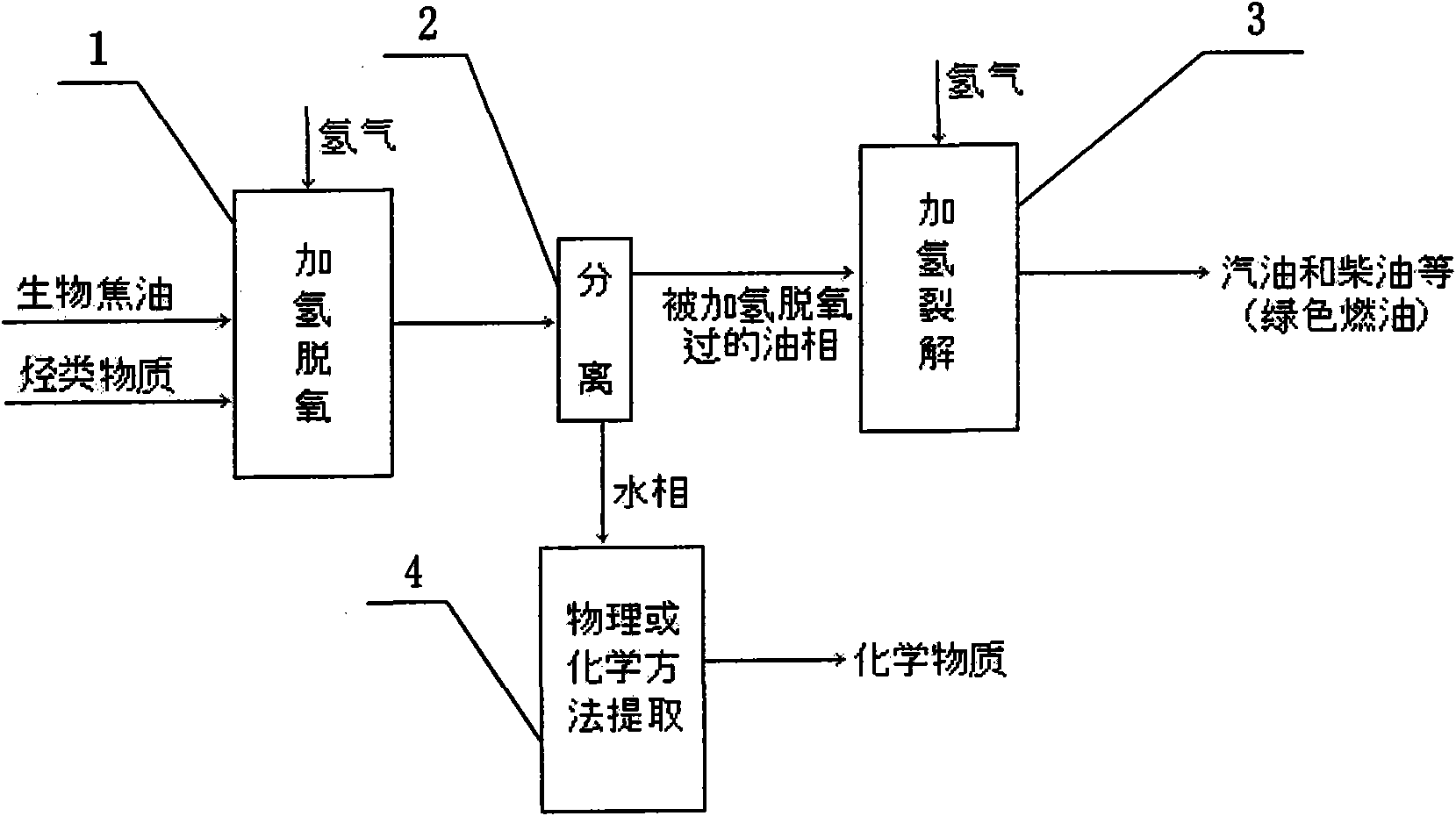

[0038] See figure 1

[0039] A. Hydrodeoxygenation: the biotar obtained from the slow pyrolysis or gasification of straw;

[0040] In the initial reaction, because there is no hydrodeoxygenated oil phase in the hydrodeoxygenation reactor 1—the ebullating bed reactor, 0.15kg propanol that promotes the mutual dissolution of biotar and hydrocarbons is added as the initial reaction Reactive additives enable biotar and hydrocarbons to form a phase under the action of external force. Hydrodeoxygenated oil phase substances will continue to be generated. When such an oil phase is formed, there is no need to add medium substances, so these medium substances are only used as additives for the initial reaction;

[0041] 1kg of biotar and 3kg of hydrocarbons are continuously added to the oil phase that has been hydrodeoxygenated, 300g of Cu / SiO 2 In the hydrodeoxygenation reactor 1 where the hydrodeoxygenation catalyst exists, the reaction temperature is 250° C. and the pressure is 10 ...

Embodiment 2

[0050] A. Hydrodeoxygenation: The biotar and hydrocarbons obtained during the rapid pyrolysis of corn stalks are continuously added to the hydrodeoxygenation reactor 1 in which the hydrodeoxygenated oil phase exists in a ratio of 2:1 —Continuous Stirred Tank Reactor (CSTR), in the case of stirring, the three dissolve into one phase. If there is a lack of hydrodeoxygenated oil phase, biotar, hydrocarbons and amyl alcohol can be added in a ratio of 2:1:5 as initial reactants. Under the control of the gas flow controller, hydrogen and nitrogen as a reference gas flow into the reactor continuously, the reaction pressure is controlled by the gas pressure regulating valve, and the reacted gas flows out of the reactor through the gas pressure regulating valve. Under the reaction conditions of 320°C and 11MPa, in 1% NiMo / Al by weight of biotar 2 o 3 Under the action of the catalyst, the biotar is partially deoxygenated. The properties of the biotar obtained from the rapid pyrolysis...

Embodiment 3

[0066] A. Hydrodeoxygenation: Add 3 kg of biotar and 1 kg of hydrocarbons obtained by rapid thermal cracking of bagasse, wood chips, straw, corn stalks, bark, wood, recycled wood, etc. Oil phase, NiMo / SiO 2 In the hydrodeoxygenation reactor with 9g of hydrodeoxygenation catalyst 1—in the circulating fixed bed reactor, the temperature is 400°C, the pressure is 16MPa and under the action of the catalyst, the weight hourly space velocity of the reaction is 4h -1 , the biotar is partially deoxygenated under the action of the hydrodeoxygenation catalyst, and the water phase formed by the deoxygenation is separated from the oil phase; the liquid treated by this equipment is divided into two layers in the separator 2. The lower layer is the water phase, which is removed and transported to the chemical substance extraction device 4—the physical adsorption device; the upper layer is the oil phase, and the oil phase is sent to the hydrocracking reactor 3—the circulating fixed bed reacto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com