Preparation process of high-purity phosphorus pentafluoride

A technology of phosphorus pentafluoride and preparation process, applied in the direction of phosphorus halide/oxyhalide, etc., can solve problems such as hidden safety hazards, reduced product performance, difficult separation, etc., and achieve the effects of effective operation, easy operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

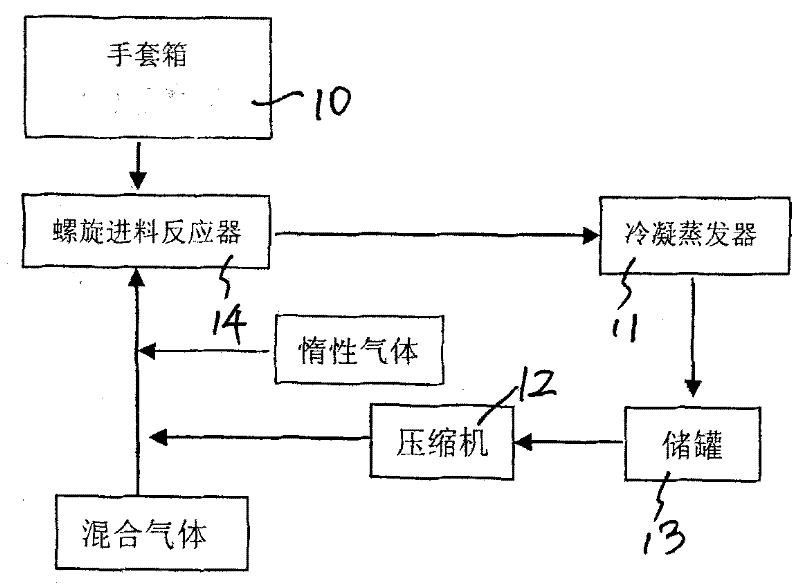

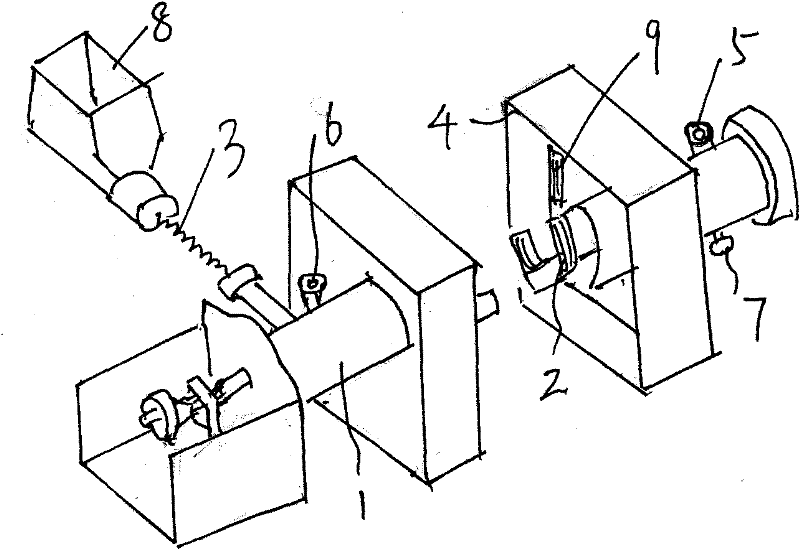

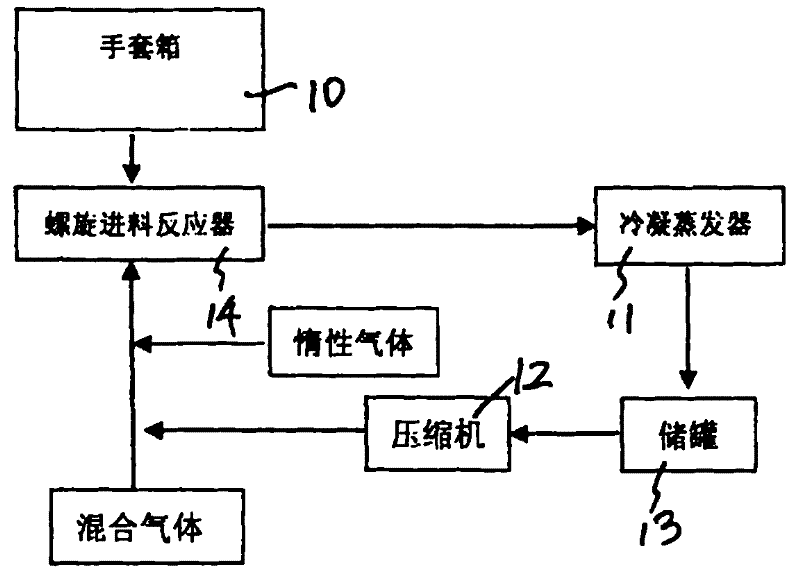

[0026] First, add 10 kg of phosphorus pentachloride to the feeding funnel of the spiral stirring reaction furnace in the glove box 10 in advance to evacuate the gas circulation loop, and then feed 0.06MPa high-purity argon into the gas circulation loop to make the condensing evaporator 11 is cooled to -180 to -140°C, and then the compressor 12 is started to circulate the gas in the gas circulation loop. Start the screw feeder of the spiral stirring reaction furnace, push phosphorus pentachloride into the reaction furnace cylinder of the spiral stirring reaction furnace, and at the same time slowly feed the mixed gas of fluorine gas and hydrogen fluoride into the gas circulation loop, and control the supply of the screw feeder. The rotation frequency of phosphorus pentachloride is 5-8 rpm, the temperature of the gas flow at the outlet of the spiral stirring reactor is controlled at 60°C-165°C, and the pressure in the gas circulation loop is controlled to be less than 0.15MPa. A...

Embodiment 2

[0031] First add 15 kg of phosphorus pentachloride to the feeding funnel of the spiral stirring reaction furnace in the glove box, vacuumize the gas circulation loop, and then pass 0.07MPa high-purity argon into the gas circulation loop to cool the condensing evaporator to -150 to -120°C, and then start the compressor to circulate the gas in the gas circulation loop. Start the screw feeder of the spiral stirring reaction furnace, push phosphorus pentachloride into the reaction furnace cylinder of the spiral stirring reaction furnace, and at the same time slowly feed the mixed gas of fluorine gas and hydrogen fluoride into the gas circulation loop, and control the supply of the screw feeder. The rotation frequency of phosphorus pentachloride is 10-12 rpm, the temperature of the gas flow at the outlet of the spiral stirring reactor is controlled at less than 400°C, and the pressure in the gas circulation loop is controlled to be less than 0.25 MPa. After the reaction, the phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com