Angiotensin converting enzyme inhibitory peptide and preparation method thereof

An angiotensin and inhibitory peptide technology, applied in the field of inhibitory peptides and their preparation, can solve the problems of low content of anti-ACE peptides, no reports of amino acid sequences, and high production costs, so as to improve the ACE inhibition rate, avoid hydrolysis inactivation, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

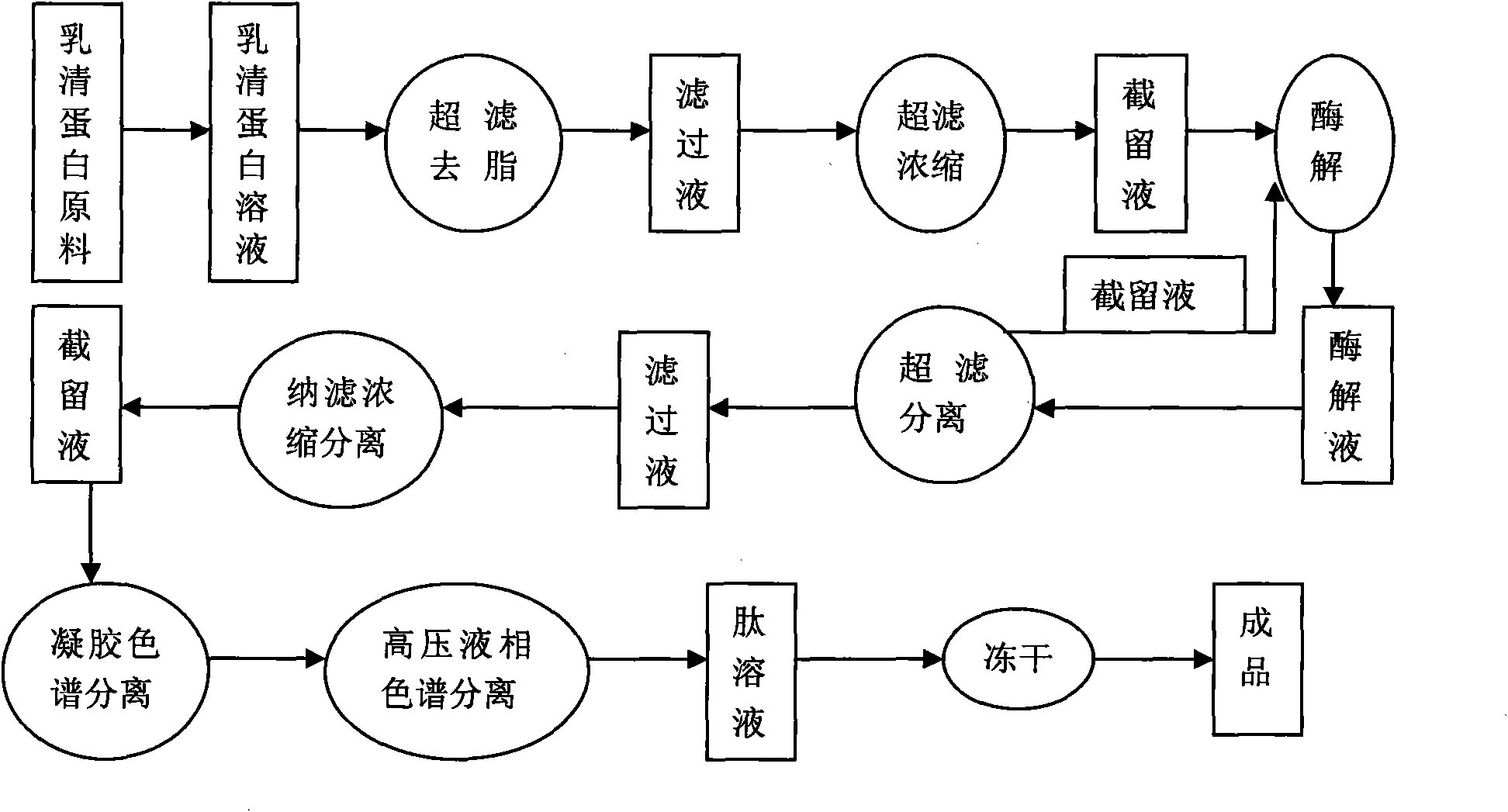

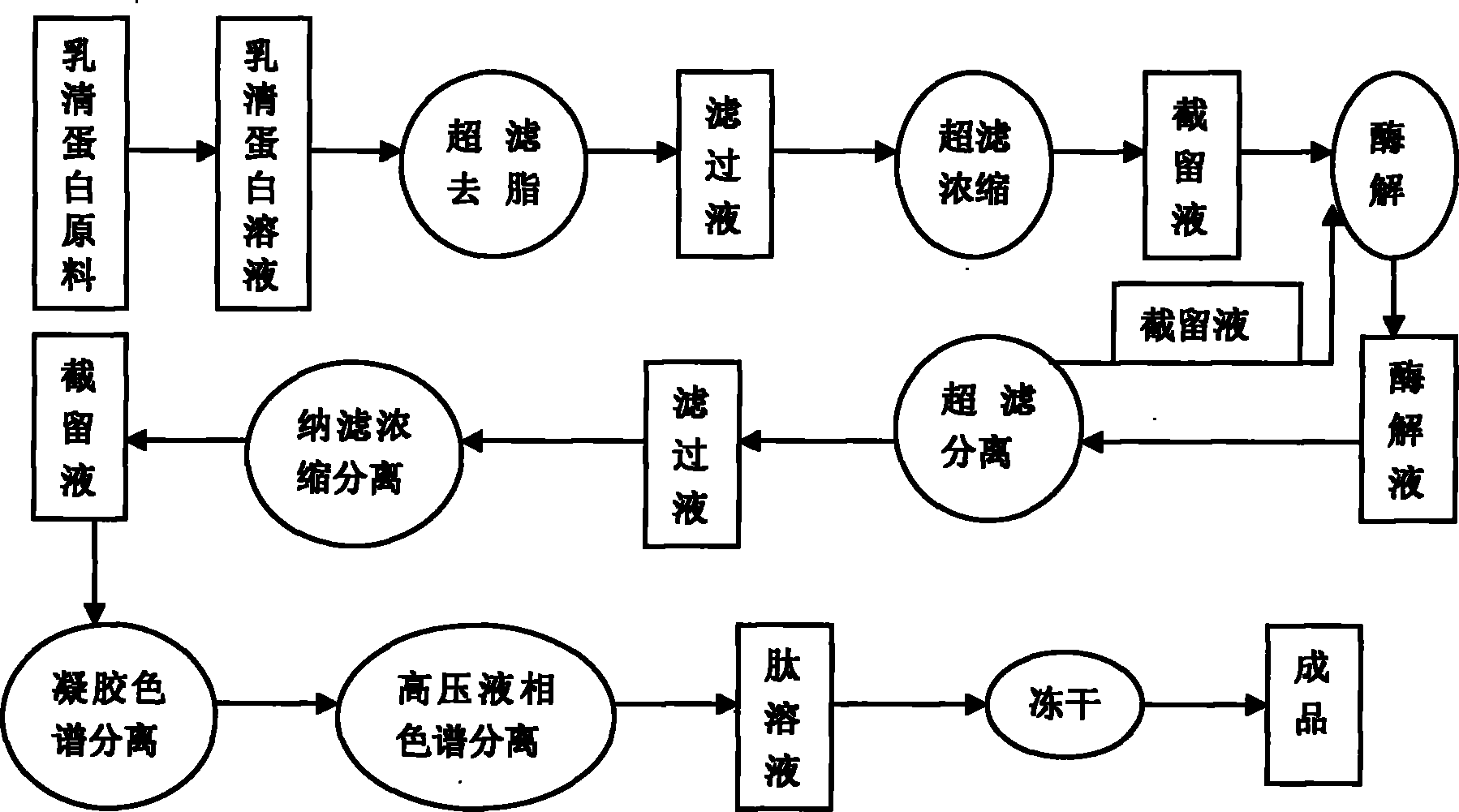

[0030] One, the preparation of whey protein source anti-ACE peptide, comprises the following steps:

[0031] 1) Preparation of whey protein concentrate: 1.0 kg of commercially available whey powder is selected and dissolved in 9 kg of warm water at a temperature of 40° C. to obtain a whey solution. The pressure is 1.0MPa, the temperature is ultrafiltration at 38°C, and the filtrate is then ultrafiltered with a polysulfone membrane with a molecular weight cut-off of 10KDa at a pressure of 1.0MPa and a temperature of 38°C, and the resulting 4.5kg whey protein is ultrafiltered The pH value of the filtered concentrate is adjusted to 8.0;

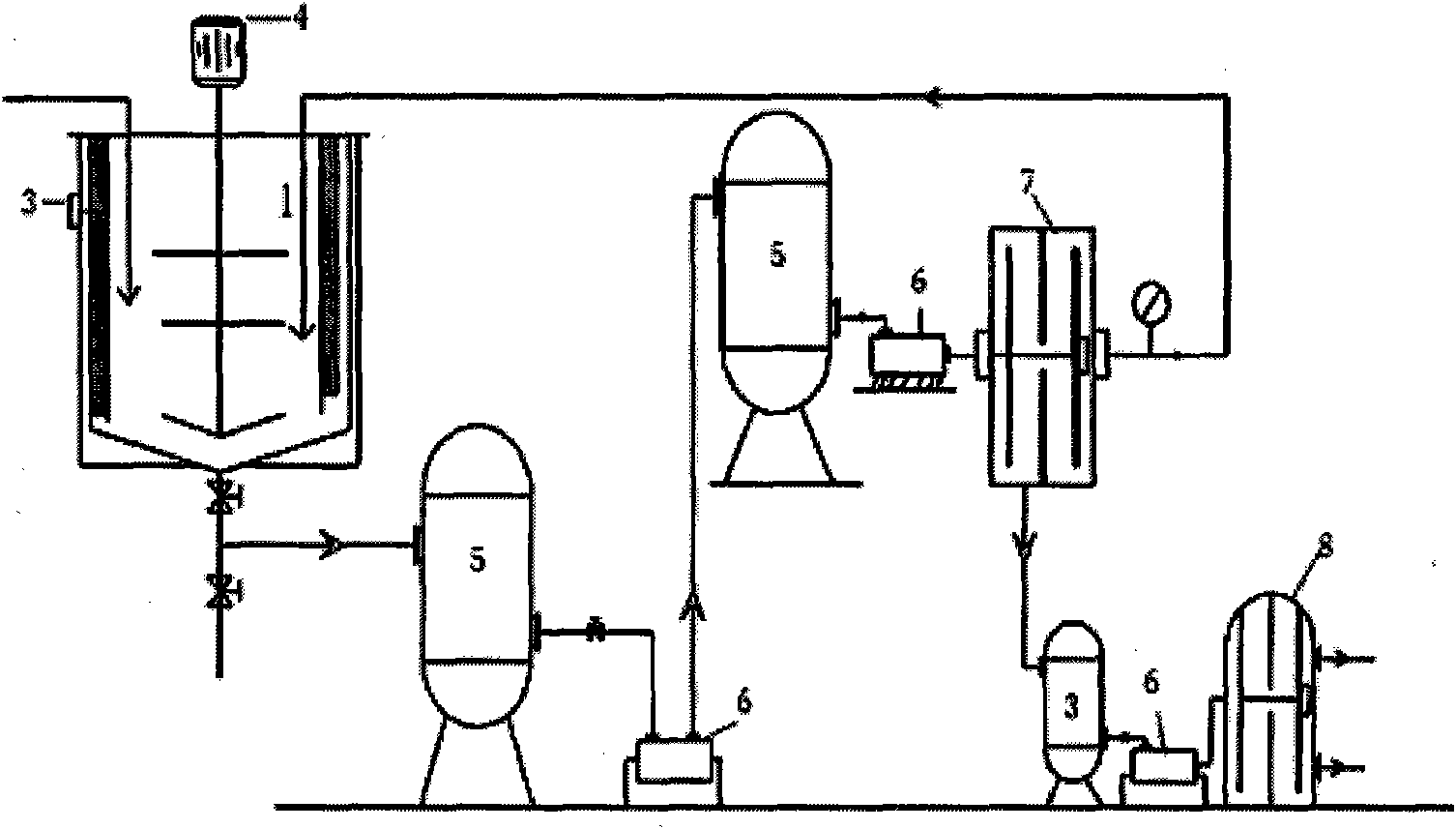

[0032] 2) Enzymolysis reaction of whey protein concentrate: add whey protein concentrate to enzymolysis reaction vessel 1, and add Lactobacillus helveticus wall protease with an activity of 500U / mg, pepsin at 2000U / mg and 1500U / mg 20 grams of mixed protease composed of trypsin, in which the mass ratio of Lactobacillus helveticus cell wall prote...

Embodiment 2

[0044] The same as Example 1, the difference is: take 12kg of fresh milk and centrifuge at 6000rpm×20min to remove the fat to obtain skim milk, then adjust the pH value of the obtained skim milk to 4.6 with 0.10N dilute hydrochloric acid, and centrifuge at 6000rpm×20min to remove the casein precipitate Obtain whey solution. Adjust the pH of the obtained whey to 7.8, and use a polysulfone membrane with a molecular weight cut-off of 10-15KDa to perform ultrafiltration at a pressure of 1.5MPa and a temperature of 38°C to remove small molecular substances such as lactose, salts, and water, and then Add the resulting 4kg whey protein ultrafiltration concentrate to enzymolysis reaction vessel 1, and add a mixture of Lactobacillus helveticus wall protease with an activity of 700U / mg, pepsin at 2500U / mg, and trypsin at 1600U / mg 15 grams of protease were hydrolyzed at 41° C. for 2.5 hours through the insulation jacket 2 and the temperature control system 3, and continuously stirred by ...

Embodiment 3

[0047] The same as in Example 1, the difference is that 1.2kg of milk powder is dissolved in 9kg of warm water at a temperature of 45°C, and the fat is removed by centrifugation at 6000rpm×20min to obtain skim milk, and the resulting skim milk is then adjusted to pH 4.6 with dilute hydrochloric acid. Centrifuge at 6000rpm×20min to remove casein precipitates to obtain whey solution. Adjust the pH of the obtained whey to 7.8, and use a polysulfone membrane with a molecular weight cut-off of 10-15KDa to perform ultrafiltration at a pressure of 1.5MPa and a temperature of 39°C to remove small molecular substances such as lactose, salts, and water, and then Put the obtained 0.5kg whey protein ultrafiltration concentrate into the enzymolysis reaction vessel 1, and add a mixture consisting of Lactobacillus helveticus wall protease with an activity of 800U / mg, pepsin at 3000U / mg and trypsin at 1800U / mg 2 grams of protease were hydrolyzed at 41.5° C. for 2.8 hours through the insulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com