Low-cost and high-performance glass fiber reinforced nylon 6 composite material and preparation method thereof

A technology of glass fiber and composite materials, which is applied in the field of glass fiber reinforced nylon materials and its preparation, can solve the problems of high price, complicated technology, and little practical value, and achieve low cost, overcome compatibility, and smooth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

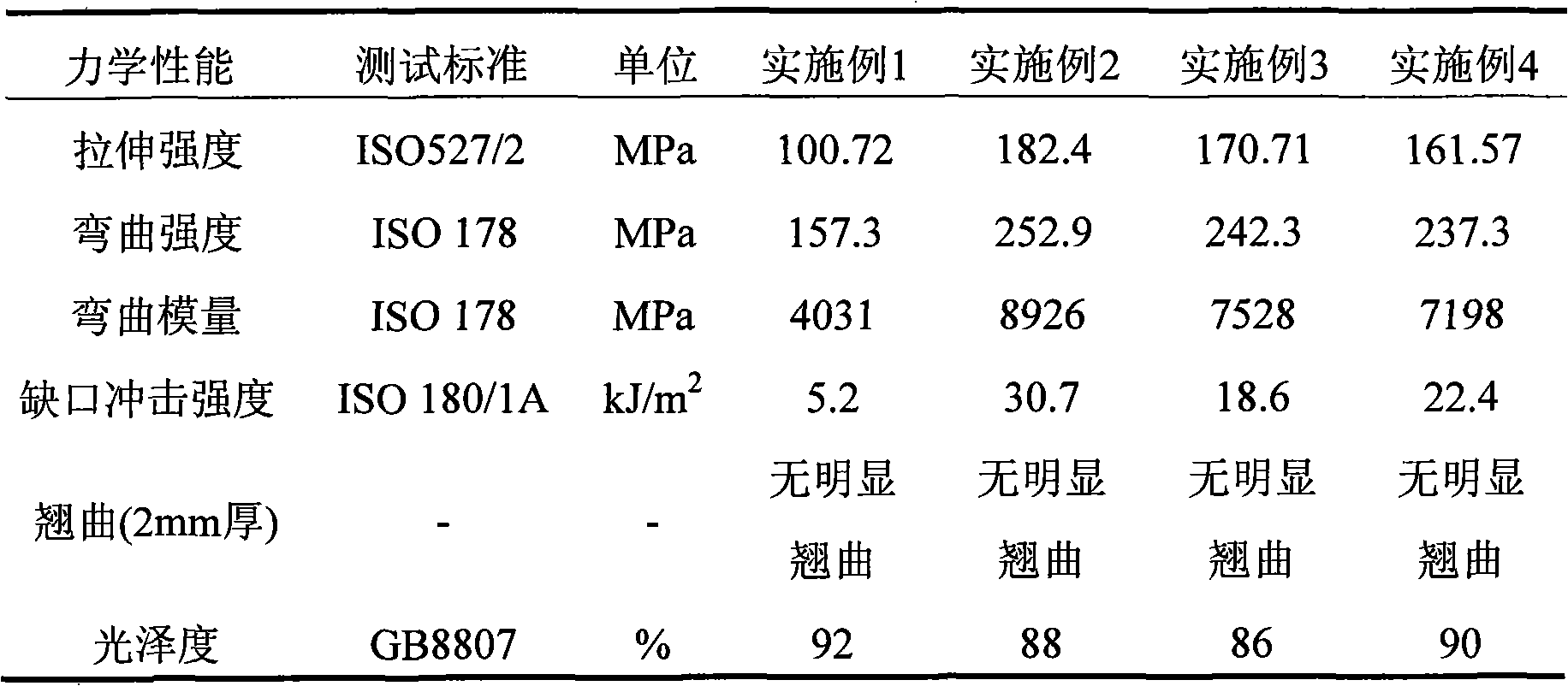

Examples

Embodiment 1

[0027] A low-cost high-performance glass fiber reinforced nylon 6 composite material, which is composed of the following raw materials in weight percentage: nylon 6 (brand: PA6VOLGAMID; manufacturer: Shanghai Kuibyshev Nitrogen Engineering Plastics Co., Ltd.) 82.5%; 4.3% calcium sulfate whisker; 0.15% nucleating agent; 0.15% primary antioxidant; 0.1% secondary antioxidant; 0.3% modified additive; 0.2% silicone oil;

[0028] The compatibilization and toughening agent is composed of 2.3% of maleic anhydride grafted polyethylene octene co-elastomer and 2% of maleic anhydride grafted EPDM rubber. The nucleating agent is ultrafine talcum powder. The main antioxidant is tris(2,4-di-tert-butyl)phenylphosphite. The secondary antioxidant is 627A (bis(2,45-di-tert-butylphenyl) pentaerythritol diphosphite, Shanghai Jinhai Yabao Fine Chemical Co., Ltd.). The modified auxiliary agent is composed of A-C540A (polyethylene wax, Shenzhen Qinling Import and Export Trade Co., Ltd.). The glass...

Embodiment 2

[0032] A low-cost high-performance glass fiber reinforced nylon 6 composite material, which is composed of the following raw materials in parts by weight: nylon 6 (brand: PA6VOLGAMID; manufacturer: Shanghai Kuibyshev Nitrogen Engineering Plastics Co., Ltd.) 57%; 14% calcium sulfate whisker; 0.4% nucleating agent; 0.4% primary antioxidant; 0.2% secondary antioxidant; 1% modified additive; 0.5% silicone oil;

[0033] Described compatibilization and toughening agent is made of maleic anhydride grafted polyethylene octene co-elastomer 6% and maleic anhydride grafted styrene-ethylene / butylene-styrene block copolymer 6% and Fusabond 560D (U.S. DuPont) 2% composition. The nucleating agent is organic bentonite. The main antioxidant is tetrakis(β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester. The secondary antioxidant is THANOX-1098 (anti-extraction, low volatility hindered phenolic antioxidant, Tianjin Ruiande Technology Development Co., Ltd.). The modified ...

Embodiment 3

[0037] A low-cost and high-performance glass fiber reinforced nylon 6 composite material, which is composed of the following raw materials in parts by weight: 70% of nylon 6 (brand: PA6VOLGAMID; manufacturer: Shanghai Kuibyshev Nitrogen Engineering Plastics Co., Ltd.); 7% calcium sulfate whisker; 0.3% nucleating agent; 0.3% primary antioxidant; 0.3% secondary antioxidant; 0.7% modified auxiliary agent; 0.4% silicone oil;

[0038] The compatibilization and toughening agent is composed of 3.5% maleic anhydride grafted styrene-ethylene / butylene-styrene block copolymer and 3.5% maleic anhydride grafted EPDM rubber. The nucleating agent is P250 (thermoplastic nucleating agent, an optimized mixture of nucleating agents of organic and inorganic components, Shanghai Niu Nuo Chemical Technology Co., Ltd.). The main antioxidant is N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine. The secondary antioxidant is THANOX-1098 (Tianjin Ruiande Technology Developme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com