Nano finishing method for preparing super hydrophilic wool fabric with washing fastness

A technology of washability and wool fabric, applied in the direction of fabric, textile, fiber treatment, etc., can solve the problems that the hydrophilic effect cannot be maintained for a long time, the washability is not very good, and the fabric feels poor, so as to achieve low cost and increase comfort Sexuality and functionality, fast-diffusing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

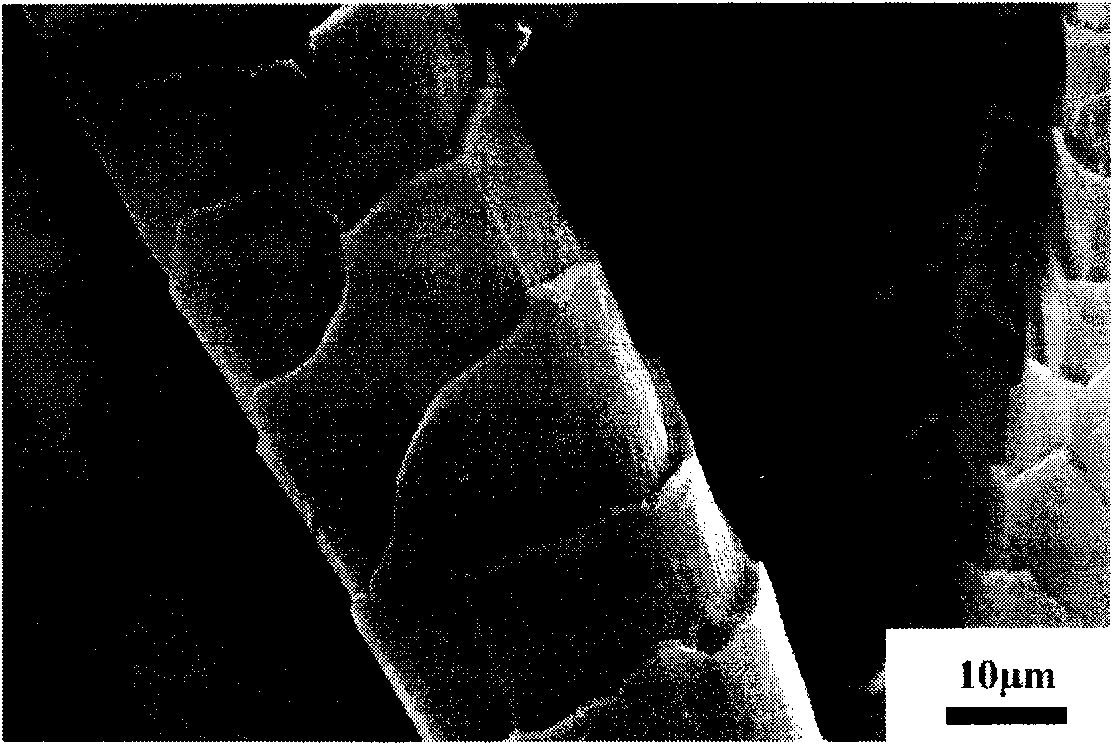

[0058] (1). Wash the woolen cloth to be treated, dry it and weigh it, then immerse it in a methanol solution containing 2M γ-aminopropyltriethoxysilane, take it out after soaking for 2 minutes, and dry it at 100°C for 5 minutes ;

[0059] (2). Put the wool cloth treated in step (1) into the aqueous solution whose pH is adjusted to 8 with ammonia water, the bath ratio is 1:80; stir; then add the ethanol solution of ethyl orthosilicate, ethyl orthosilicate The mass fraction of the ester in the aqueous solution is 10%, and stirred at a constant temperature of 80°C for 10 minutes; the pH value of the above reaction solution is adjusted to 4 with hydrochloric acid, and then shaken at a constant temperature of 70°C for 20 minutes;

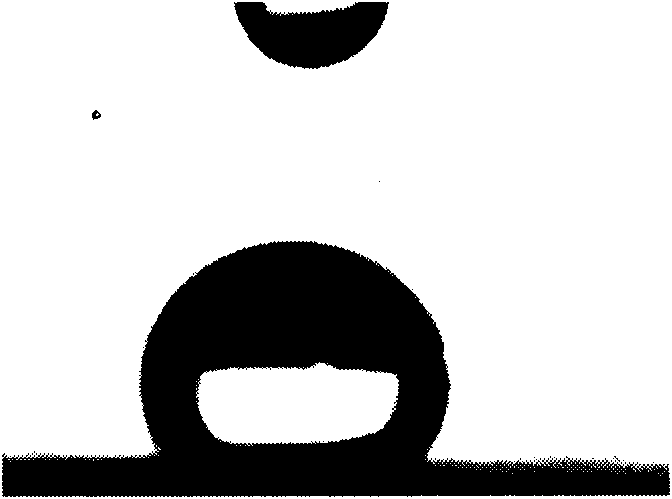

[0060] (3). The woolen cloth after step (2) is taken out, rinsed three times with tap water, and dried to obtain super-hydrophilic woolen cloth with washability (the contact angle between the fiber surface of the woolen cloth and water is zero degree) ....

Embodiment 2

[0063] (1). Wash the cashmere cloth to be treated, dry and weigh it, then immerse it in a toluene solution containing 2mM γ-aminopropyltrimethoxysilane, take it out after soaking for 10 hours, and dry it at 40°C for 300 minutes;

[0064] (2). The cashmere cloth processed by step (1) is put into the mixed solution of water and ethanol (volume ratio is 1: 1) adjusted to pH 14 with potassium hydroxide, and the bath ratio is 1: 100; Stir; Then add methanol solution of methyl orthosilicate, the mass fraction of methyl orthosilicate in the mixed solution of water and ethanol is 0.1%, stir at constant temperature at 60°C for 300 minutes; adjust the pH value of the above reaction solution with hydrochloric acid 1, then shake at a constant temperature of 100°C for 60 minutes;

[0065] (3). The cashmere cloth after step (2) is taken out, rinsed three times with tap water, and dried to obtain super-hydrophilic cashmere cloth with washability (the contact angle between the fiber surface o...

Embodiment 3

[0067] (1). Wash the woolen cloth to be treated, dry and weigh it, and then immerse it in the tetrachlorethylene solution containing 200mM γ-glycidyl etheroxypropyl trimethoxysilane, take it out after soaking for 30 minutes, and take it out at 60 Dry at ℃ for 20 minutes;

[0068] (2). Putting the wool cloth treated by step (1) into pH 10 mixed (molar ratio is 1: 1) aqueous solution of sodium hydroxide and ammonia water, the bath ratio is 1: 50; stir; then add nitric acid Silver solid powder is then added to an aqueous solution of sodium silicate, wherein the mass fraction of silver nitrate in the aqueous solution is 5%, and the mass fraction of sodium silicate in the aqueous solution is 1%. Stir at a constant temperature of 80°C for 2 minutes; adjust with acetic acid The pH value of the above reaction solution is 3, and then shake at a constant temperature of 80° C. for 30 minutes;

[0069] (3). The woolen cloth after step (2) is taken out, rinses three times with tap water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com