Methods for preparing and extracting betaine and betaine hydrochloride

An extraction method and betaine technology, which are applied in the preparation of organic compounds, chemical instruments and methods, and cyanide reaction preparation, etc., can solve the problems of low product purity, large consumption of raw materials, large investment, etc. The effect of low consumption, good product quality and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

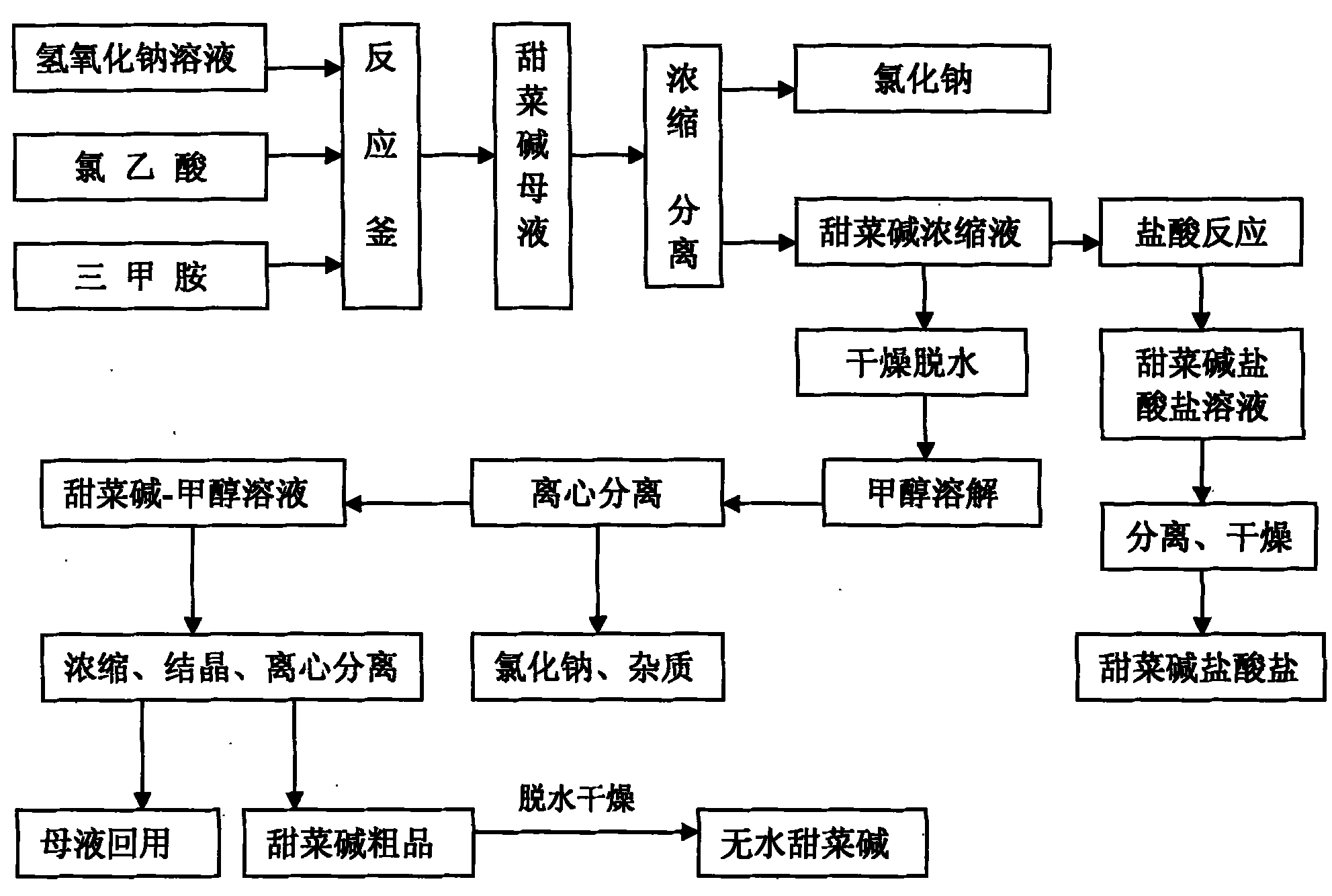

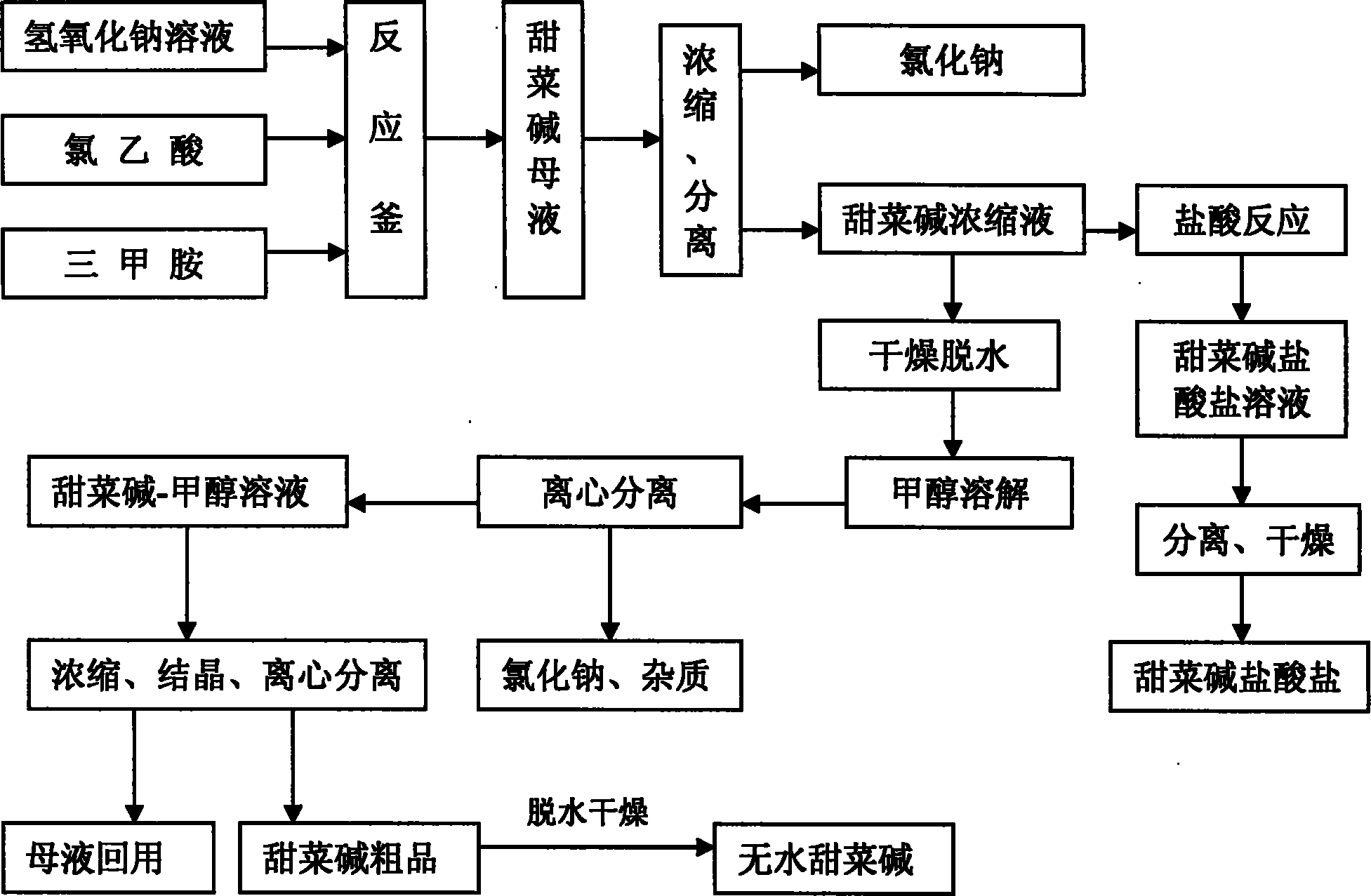

Method used

Image

Examples

Embodiment 1

[0023] 1, the preparation of betaine concentrate

[0024] (1) Pour 30% sodium hydroxide solution into the reaction kettle, then add pure chloroacetic acid to the sodium hydroxide solution, start stirring and allow it to fully react, and keep the temperature at 30-45°C.

[0025] (2) When the temperature of the solution drops to 20-30°C, pour liquid trimethylamine into the reaction kettle, and stir to make it fully react.

[0026] (3) The betaine aqueous solution is placed in a concentration kettle and concentrated to 80% of the volume of the original solution.

[0027] (4) After separating and removing the precipitated sodium chloride crystals, the betaine concentrate is obtained.

[0028] 2. Preparation and extraction of anhydrous betaine

[0029] (1) The concentrated betaine solution is dried to remove the remaining 70-100% of water, and the temperature is kept at 100-120°C.

[0030] (2) Add liquid methanol to the obtained mixture at 1-3 times the amount, stir and heat to ...

Embodiment 2

[0043]Preparation and extraction of embodiment 2 anhydrous betaine

[0044] (1) Put the sodium hydroxide solution that the mass percent concentration is 40% into the reactor, then add chloroacetic acid in the sodium hydroxide solution, start stirring to make it fully react, and keep the temperature at 45°C; When cooling to 30°C, pour liquid trimethylamine into the reaction kettle, start stirring to make it fully react; after the reaction is completed, place the betaine mother liquor in a concentration kettle to concentrate, separate and remove the precipitated sodium chloride crystals, and obtain betaine The concentrated solution; the mol ratio of sodium hydroxide, chloroacetic acid and trimethylamine in the sodium hydroxide solution is sodium hydroxide: chloroacetic acid: trimethylamine=1:1:1.

[0045] (2) Drying the concentrated solution of the synthesized betaine to remove the remaining 99.9% of water, the temperature is controlled at 120°C; then adding methanol to it with ...

Embodiment 3

[0048] Preparation and extraction of embodiment 3 anhydrous betaine

[0049] (1) Put the sodium hydroxide solution that is 25% by mass percent concentration into the reactor, then add chloroacetic acid to the sodium hydroxide solution, start stirring to make it fully react, and keep the temperature at 40°C; When cooling to 25°C, pour liquid trimethylamine into the reaction kettle, start stirring to make it fully react; after the reaction is completed, place the betaine mother liquor in a concentration kettle to concentrate, separate and remove the precipitated sodium chloride crystals, and obtain betaine The concentrated solution; the mol ratio of sodium hydroxide, chloroacetic acid and trimethylamine in the sodium hydroxide solution is sodium hydroxide: chloroacetic acid: trimethylamine=1:1:1.

[0050] (2) Drying the concentrated solution of the synthesized betaine to remove the remaining 99.95% of the water, the temperature is controlled at 150°C; then adding methanol to it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com