Composite anode material of graphene nanoflakes and cobalt hydroxide for lithium ion battery and preparation method thereof

A technology of graphene nanosheets and lithium-ion batteries, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of first-time charge-discharge efficiency and cycle performance, cumbersome process steps, low conductivity, etc., and achieve excellent Cyclic performance, simple preparation process, and the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

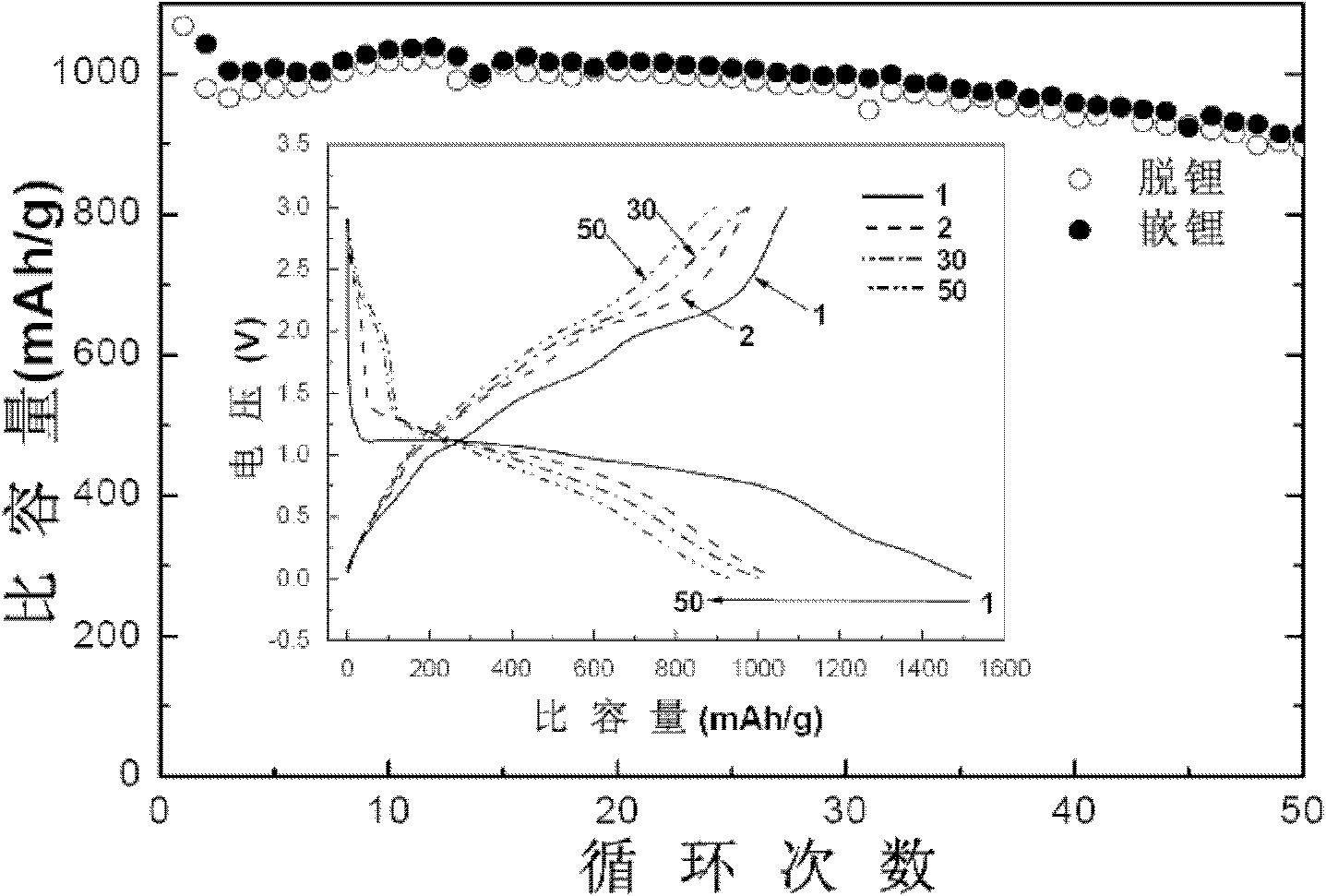

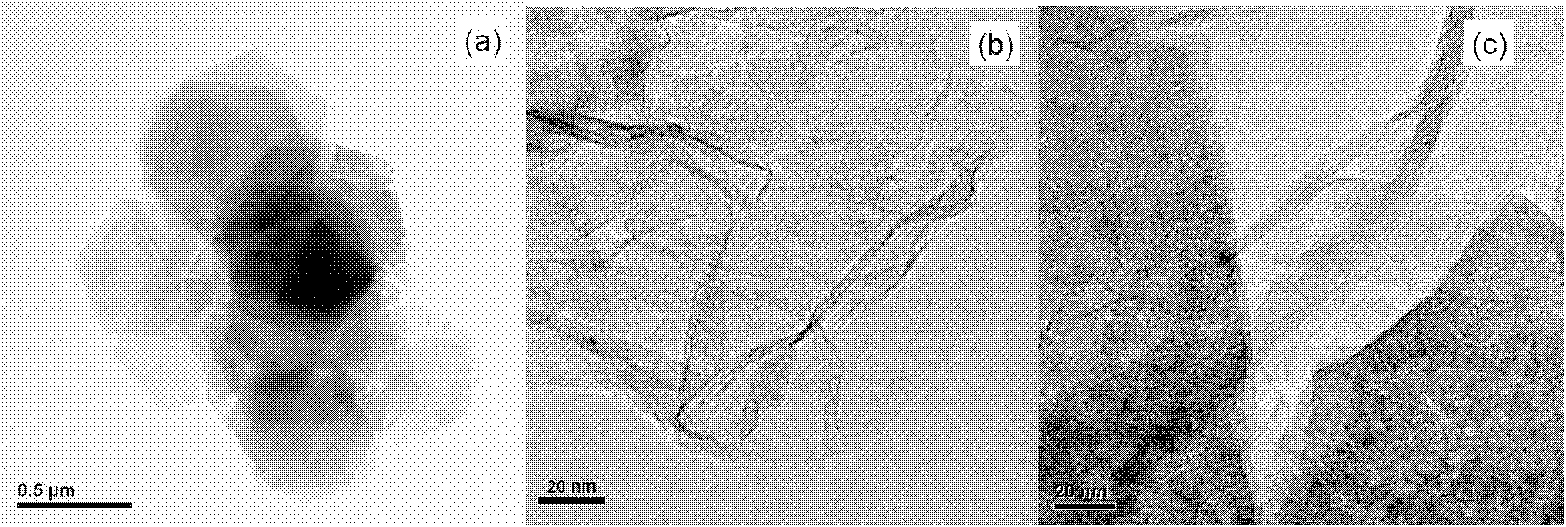

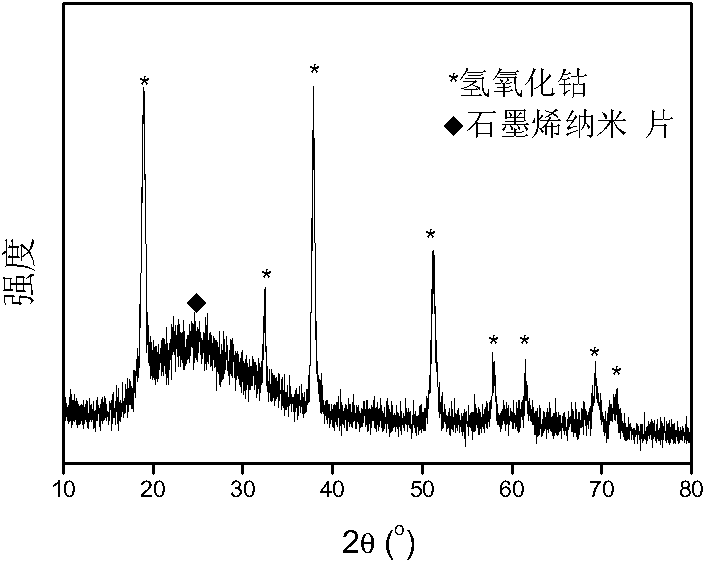

[0024] Disperse 0.5 g of graphite oxide in 400 ml of aqueous solution, ultrasonic time is 6 hours, add 2.79 g of cobalt acetate tetrahydrate, 10 ml of hydrazine hydrate, and 15 ml of ammonia water, stir and pour into a hydrothermal kettle, seal it, and heat it at 150 degrees Celsius After reacting for 5 hours, filter, wash and dry to obtain the graphene nanosheet-cobalt hydroxide negative electrode material, wherein the weight percentage of the graphene nanosheet is 24.6%. figure 1 In a is cobalt hydroxide prepared under the same conditions, figure 1 b is the graphene nanosheets prepared under the same conditions and figure 1 c is a transmission electron microscope image of the graphene nanosheet-cobalt hydroxide negative electrode material, and it can be clearly seen that the graphene nanosheets are interlacedly distributed on the surface of the cobalt hydroxide particle. figure 2 The X-ray diffraction spectrum of the graphene nanosheet-cobalt hydroxide anode material can s...

Embodiment 2

[0026] Disperse 0.5 g of graphite oxide in 300 ml of isopropanol-water solution (volume ratio of 1:10), stir at room temperature for 6 hours, add 3.26 g of cobalt nitrate hexahydrate, 15 ml of ammonia, 0.08 g of sodium borohydride, and stir Pour into a hydrothermal kettle, seal, and filter, wash, and dry after reacting at 120 degrees Celsius for 5 hours to obtain a graphene nanosheet-cobalt hydroxide negative electrode material, wherein the weight percentage of graphene nanosheets is 25.5 %. The reversible specific capacity of the charge-discharge test at a current density of 200mA / g is 820mAh / g.

Embodiment 3

[0028] Disperse 0.5 grams of graphite oxide in 300 ml of isopropanol-water solution (volume ratio is 1:15), ultrasonic time is 2 hours, add 3.26 grams of cobalt sulfate heptahydrate, 15 milliliters of ammonia water, 0.1 grams of ascorbic acid, pour into water after stirring In a hot kettle, sealed, and reacted at 200 degrees Celsius for 10 hours, filtered, washed, and dried to obtain a graphene nanosheet-cobalt hydroxide negative electrode material, wherein the weight percentage of the graphene nanosheet is 23.9%. The reversible specific capacity of the charge-discharge test at a current density of 200mA / g is 905mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com