Production process of pumpkin powder and product thereof

A production process, pumpkin powder technology, applied in the direction of dehydration preservation of fruits/vegetables, etc., can solve the problems of pumpkin powder sticking to the wall and gelatinization, difficult control of process conditions, high process cost, etc., to achieve loose hand feeling, good nutrition and color maintenance , The effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1. Preparation of pumpkin powder

[0017] Get fresh pumpkin (kind is Hei Ji) as raw material, measure each nutritional index according to the following methods:

[0018] Moisture measurement method: Turn on the blower in the oven, put the chopped pumpkin into a large petri dish, put the petri dish into the oven, and dry it for 48 hours at 55°C-60°C, turning over every two hours. Weigh after 48 hours. After the moisture drops below 10%, change to 105°C and dry continuously for 1 hour, then open the oven door slightly, wait for the temperature to drop slowly, cool for 10-15 minutes, and then enter the dryer to stabilize for 30 Minutes, weighed, and repeated drying at 105°C until the weight of the two weighings was constant. Moisture (%) = sample mass after drying / total sample mass.

[0019] Determination method of total protein: According to GB T5009.5-2003, it is determined by Kjeldahl method.

[0020] Fat determination method: according to GBT5009.6-2003, determined ...

Embodiment 2

[0056] 1. Preparation of pumpkin powder

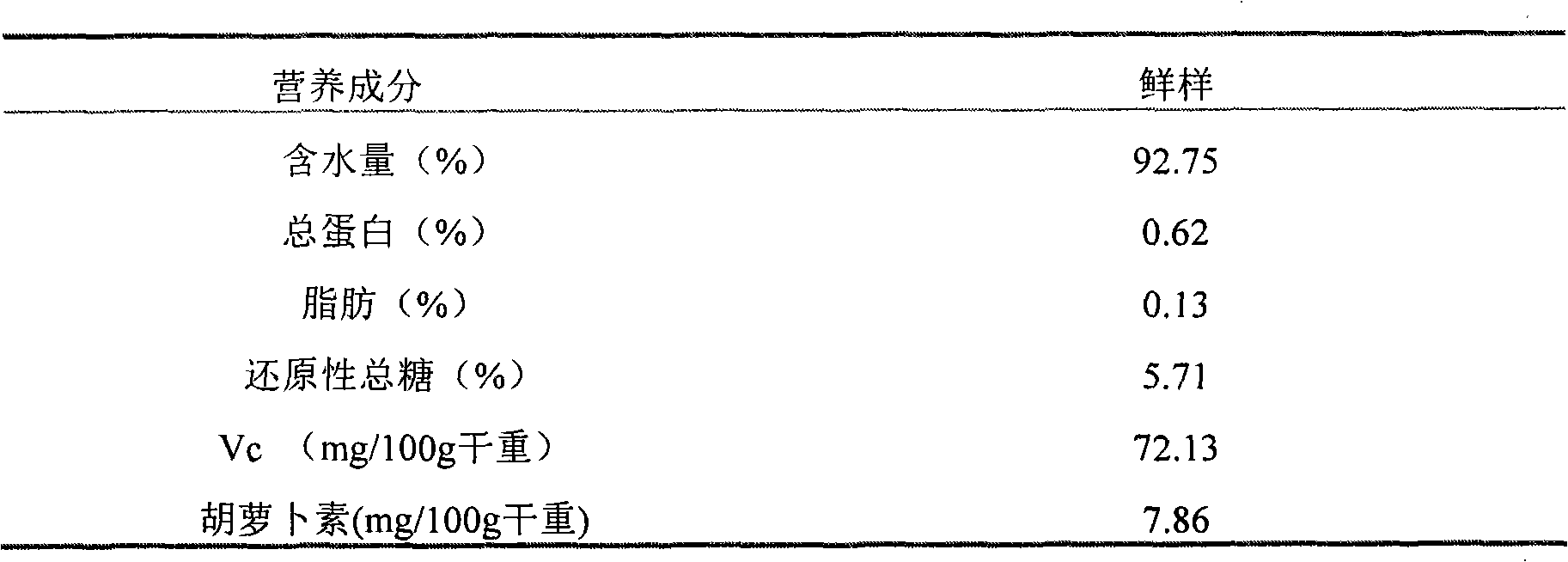

[0057] Take fresh pumpkin (the kind is Jinhongmei) as raw material, measure its water content, reducing total sugar, protein content, fat content, Vc content and other indicators according to the method described in step 1 of embodiment 1, and the results are shown in table 5:

[0058] Table 5 Index determination of fresh pumpkin

[0059]

[0060]

[0061] Production steps of pumpkin powder: cleaning of raw materials, peeling and slicing, blanching, freezing, pre-drying, homogenizing, vacuum microwave pre-expansion, pressure-difference puffing and drying, cooling, and superfine grinding; the specific methods are as follows:

[0062] 1. Cleaning of raw materials: Rinse with clean water to remove surface dirt.

[0063] 2. Peeling and slicing: Use a peeling machine to remove the skin of the pumpkin, and cut the pumpkin into 5mm thick slices.

[0064] 3. Blanching: Blanch the pumpkin slices processed in step 2 for 3 minutes in a 95...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com