Making method of mulberry leaf granules

A production method and mulberry leaf technology are applied in the field of production of mulberry leaf granules, which can solve the problem that mulberry leaves are not made into granules, and achieve the effects of improving sensory evaluation, increasing drying speed, and reducing rapid loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

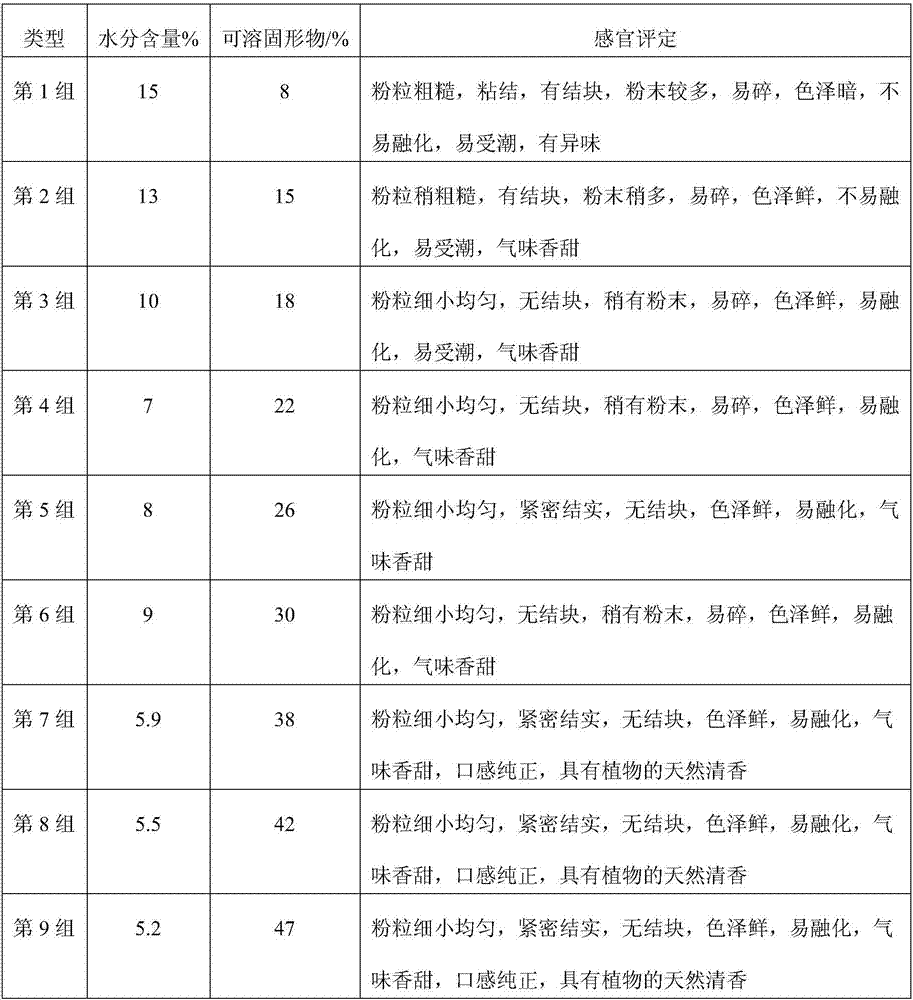

Examples

Embodiment 1

[0029] A kind of preparation method of mulberry leaf granule, specifically comprises the following steps:

[0030] (1) Select fresh raw materials according to the following parts by weight: 40 parts of mulberry leaves, 15 parts of Moringa leaves, 10 parts of beet tubers, 5 parts of sweet-scented osmanthus and 10 parts of auxiliary materials;

[0031] The auxiliary material is mainly composed of the following raw materials in parts by weight: 2 parts of protein sugar, 5 parts of honey, 0.1 part of hydroxymethyl propyl cellulose, 0.1 part of dispersant, 1 part of thickener, 2 parts of drying aid and 3 parts of nutritional enhancer share;

[0032] Among them, the drying aid is made of corn starch, maltodextrin and β-cyclodextrin according to the mass ratio of 2:1:1; the thickener is made of oxidized starch, agar and calcium caseinate according to the ratio of 1:1 : 1 mass ratio is mixed; nutrition enhancer is mixed with equal mass ratio of ferrous gluconate and casein phosphopep...

Embodiment 2

[0043] A kind of preparation method of mulberry leaf granule, specifically comprises the following steps:

[0044] (1) Select fresh raw materials according to the following parts by weight: 45 parts of mulberry leaves, 17 parts of Moringa leaves, 13 parts of beet tubers, 6 parts of sweet-scented osmanthus and 13 parts of auxiliary materials;

[0045] The auxiliary material is mainly composed of the following raw materials in parts by weight: 2.5 parts of protein sugar, 6 parts of honey, 0.2 parts of hydroxymethyl propyl cellulose, 0.2 parts of dispersant, 1.5 parts of thickener, 2.5 parts of drying aid and 4 parts of nutritional enhancer share;

[0046] Among them, the drying agent is made of corn starch, maltodextrin and β-cyclodextrin according to the mass ratio of 2.5:1:1; the thickener is made of oxidized starch, agar and calcium caseinate according to the ratio of 1.5:1 : 1.5 mass ratio mixed; nutrition enhancer is mixed with equal mass ratio of ferrous gluconate and casei...

Embodiment 3

[0057] A kind of preparation method of mulberry leaf granule, specifically comprises the following steps:

[0058] (1) Select fresh raw materials according to the following parts by weight: 50 parts of mulberry leaves, 20 parts of Moringa leaves, 15 parts of beet tubers, 7 parts of sweet-scented osmanthus and 15 parts of auxiliary materials;

[0059] The auxiliary material is mainly composed of the following raw materials in parts by weight: 3 parts of protein sugar, 7 parts of honey, 0.3 parts of hydroxymethyl propyl cellulose, 0.3 parts of dispersant, 2 parts of thickener, 3 parts of drying aid and 5 parts of nutritional enhancer share;

[0060] Among them, the drying agent is made of corn starch, maltodextrin and β-cyclodextrin according to the mass ratio of 3:1:1; the thickener is made of oxidized starch, agar and calcium caseinate according to the ratio of 2:1 : 2 mass ratio mixed; nutrition enhancer is mixed with equal mass ratio of ferrous gluconate and casein phosphop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com