Green preparation method of graphene based on tea polyphenol/green tea juice

A technology of tea polyphenols and green tea juice, which is applied in the field of graphene preparation based on tea polyphenols/green tea juice as a reducing agent, can solve the problems of harsh experimental conditions, graphene agglomeration, environmental pollution, etc., and achieve good biocompatibility, Good dispersibility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

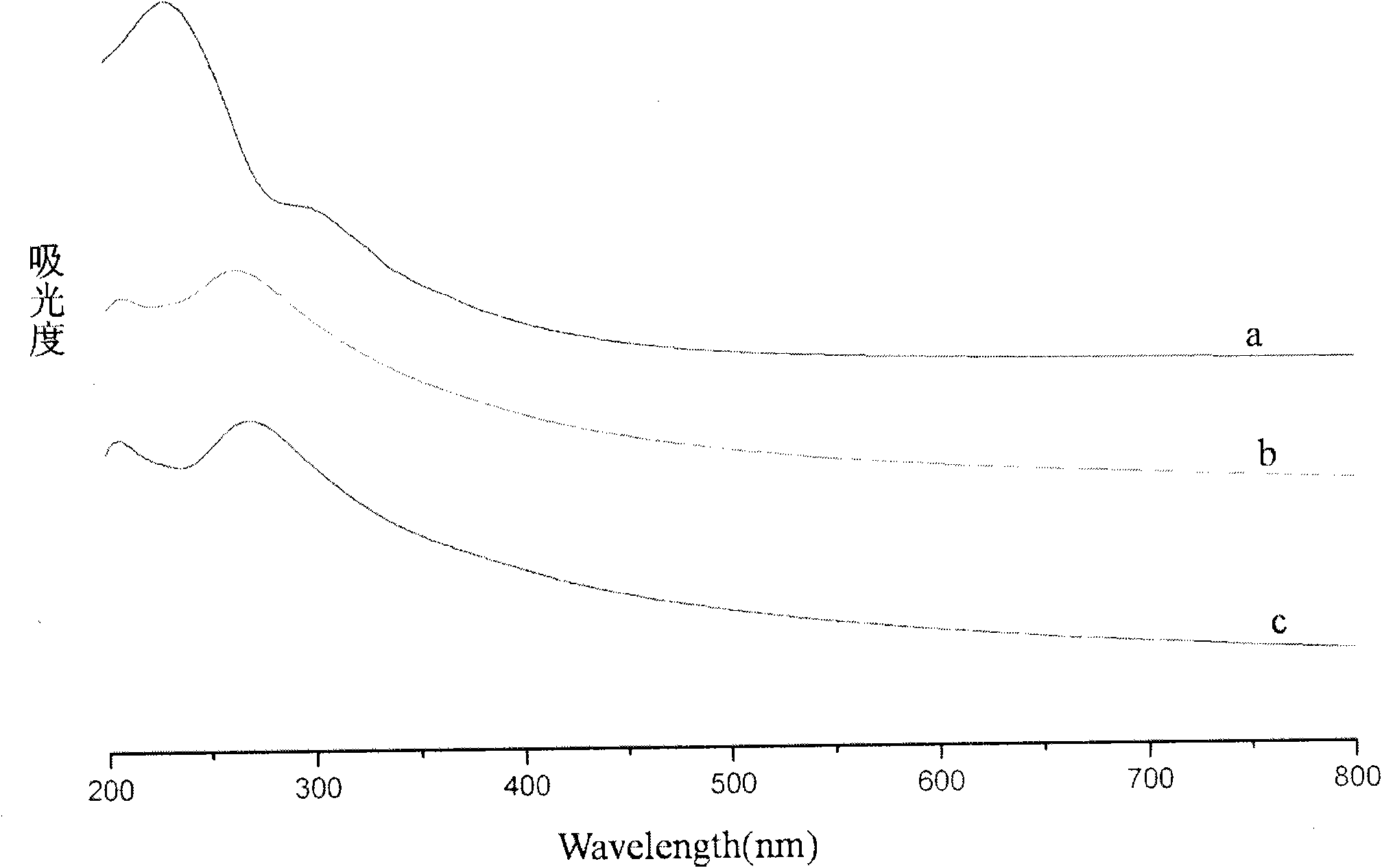

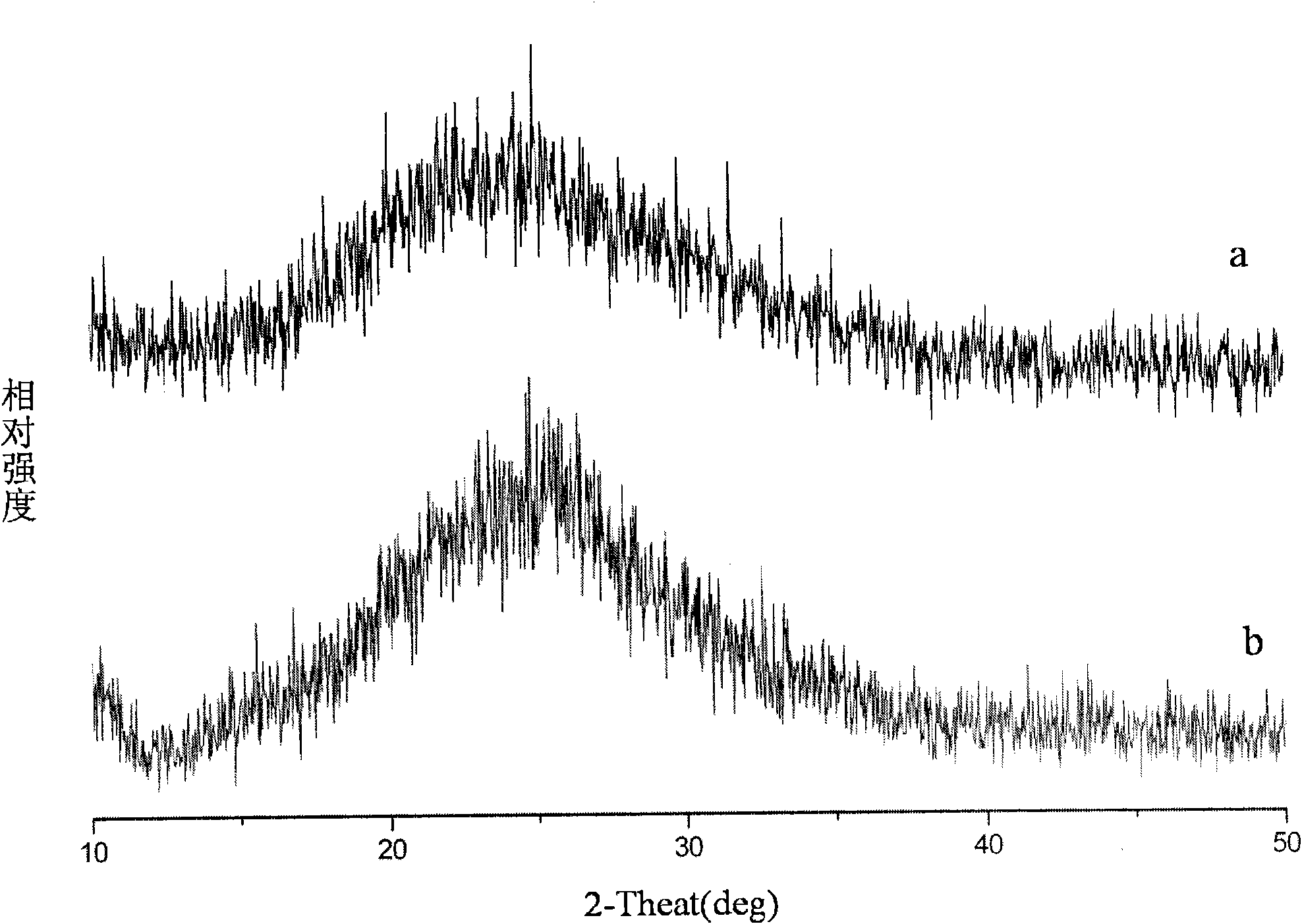

[0020] a) Add 2.5g of potassium persulfate and 2.5g of phosphorus pentoxide to 12mL of hot concentrated sulfuric acid at 90°C, mix and stir until the solid is completely dissolved, cool the mixture to 80±1°C, add 3g of graphite powder, and mix well. React in a water bath at 80±1°C for 4.5 hours; cool the mixture to room temperature, dilute it with 0.5L double-distilled water and let it stand overnight, then filter and separate it with a 0.22 micron-pore cellulose acetate filter, and wash it with a large amount of double-distilled water , the filter cake was naturally dried at room temperature; the above product, namely pre-oxidized graphite, was added to 120 mL of ice-bathed concentrated sulfuric acid under stirring conditions, and 15 g of potassium permanganate was slowly added while stirring, and the mixture was stirred and reacted for 0.5 hours under ice-bath conditions. ;The temperature of the water bath was raised to 35±1°C and the reaction was stirred for 2 hours; while s...

Embodiment 2

[0025] a) Add 2.5g of potassium persulfate and 2.5g of phosphorus pentoxide to 12mL of hot concentrated sulfuric acid at 90°C, mix and stir until the solid is completely dissolved, cool the mixture to 80±1°C, add 3g of graphite powder, and mix well. React in a water bath at 80±1°C for 4.5 hours; cool the mixture to room temperature, dilute it with 0.5L double-distilled water and let it stand overnight, then filter and separate it with a 0.22 micron-pore cellulose acetate filter, and wash it with a large amount of double-distilled water , the filter cake was naturally dried at room temperature; the above product, namely pre-oxidized graphite, was added to 120 mL of ice-bathed concentrated sulfuric acid under stirring conditions, and 15 g of potassium permanganate was slowly added while stirring, and the mixture was stirred and reacted for 0.5 hours under ice-bath conditions. ;The temperature of the water bath was raised to 35±1°C and the reaction was stirred for 2 hours; while s...

Embodiment 3

[0030] a) Add 2.5g of potassium persulfate and 2.5g of phosphorus pentoxide to 12mL of hot concentrated sulfuric acid at 90°C, mix and stir until the solid is completely dissolved, cool the mixture to 80±1°C, add 3g of graphite powder, and mix well. React in a water bath at 80±1°C for 4.5 hours; cool the mixture to room temperature, dilute it with 0.5L double-distilled water and let it stand overnight, then filter and separate it with a 0.22 micron-pore cellulose acetate filter, and wash it with a large amount of double-distilled water , the filter cake was naturally dried at room temperature; the above product, namely pre-oxidized graphite, was added to 120 mL of ice-bathed concentrated sulfuric acid under stirring conditions, and 15 g of potassium permanganate was slowly added while stirring, and the mixture was stirred and reacted for 0.5 hours under ice-bath conditions. ;The temperature of the water bath was raised to 35±1°C and the reaction was stirred for 2 hours; while s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com