High-frequency ultra pulse three-dimensional semiconductor electrode water treatment reactor technology

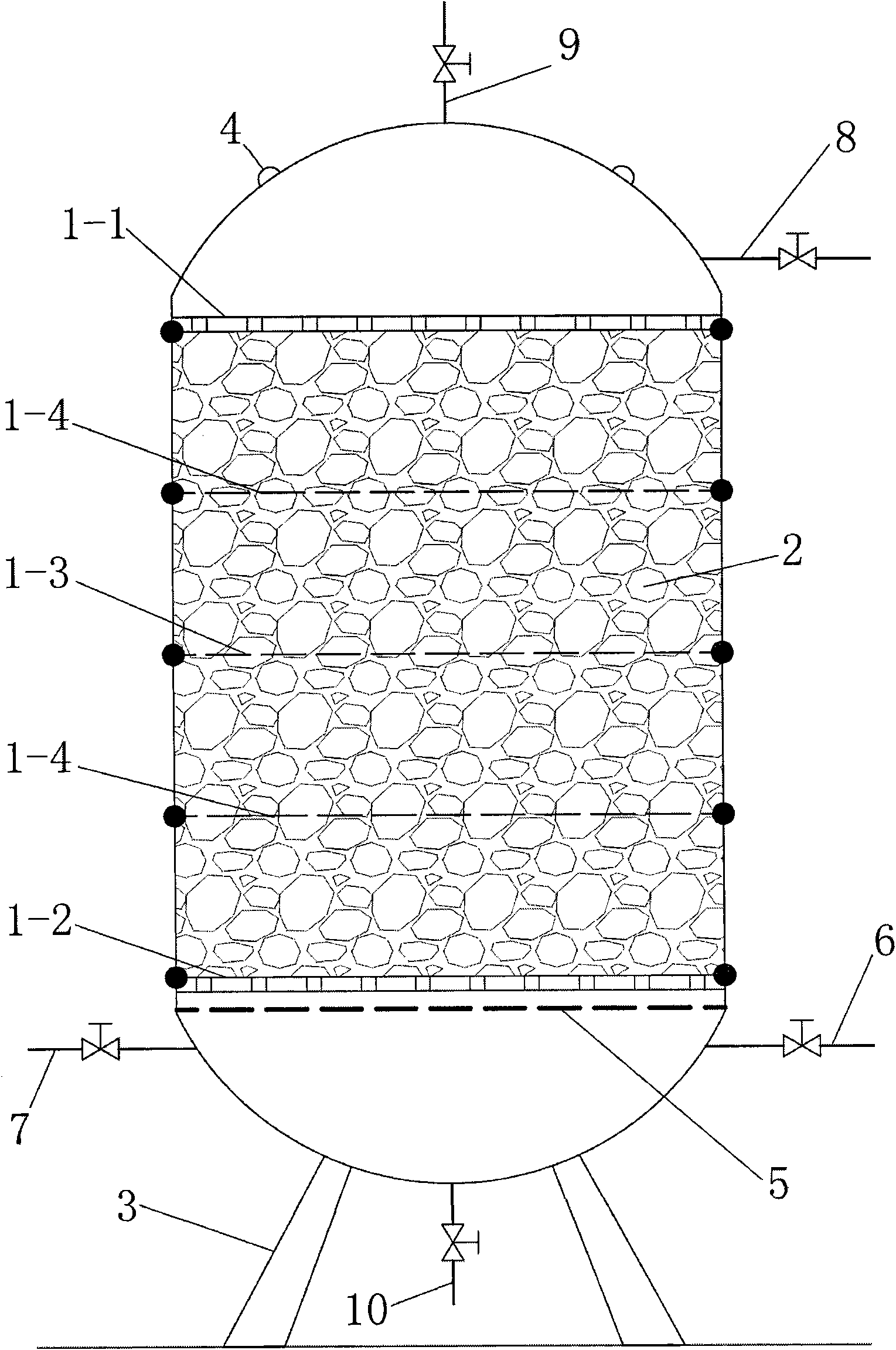

An electrode reactor and three-dimensional electrode technology, which is applied in the fields of high-frequency ultra-pulse power supply, three-dimensional semiconductor electrode preparation, sewage treatment, and reactor structure. It can solve the problems of no rectification power supply system, poor applicability of the reactor, and easy precipitation of catalytic materials. , to achieve the effect of eliminating the decline of treatment effect, eliminating the loss of catalyst and strong lattice activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Main parameters and performance of high-frequency ultra-pulse power generator: output voltage: average voltage 0~90V, output square wave pulse frequency 10KHZ~20KHZ, output pulse duty ratio 25%≤d≤100%; output maximum average current 100A; The voltage, duty cycle, current, and frequency are continuously adjustable; the output voltage polarity control is required to be controlled within 10 seconds, and the maximum is not more than 10 seconds; display requirements: average voltage, peak voltage, current, frequency, and duty cycle; the line is Closed-loop design and requires overcurrent, overvoltage, current limiting, voltage limiting, overheating protection devices; soft start function.

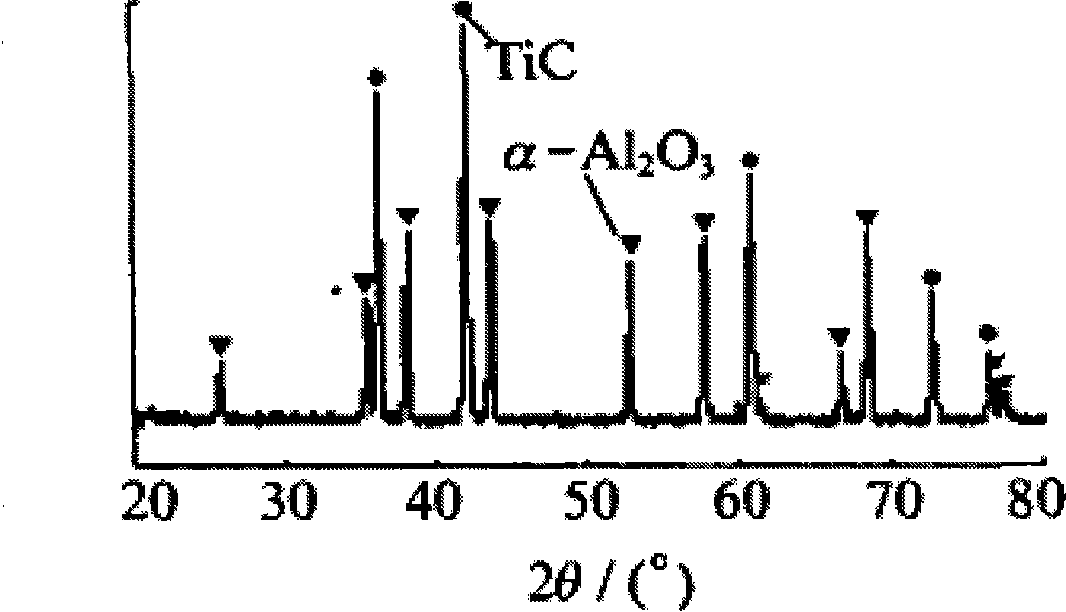

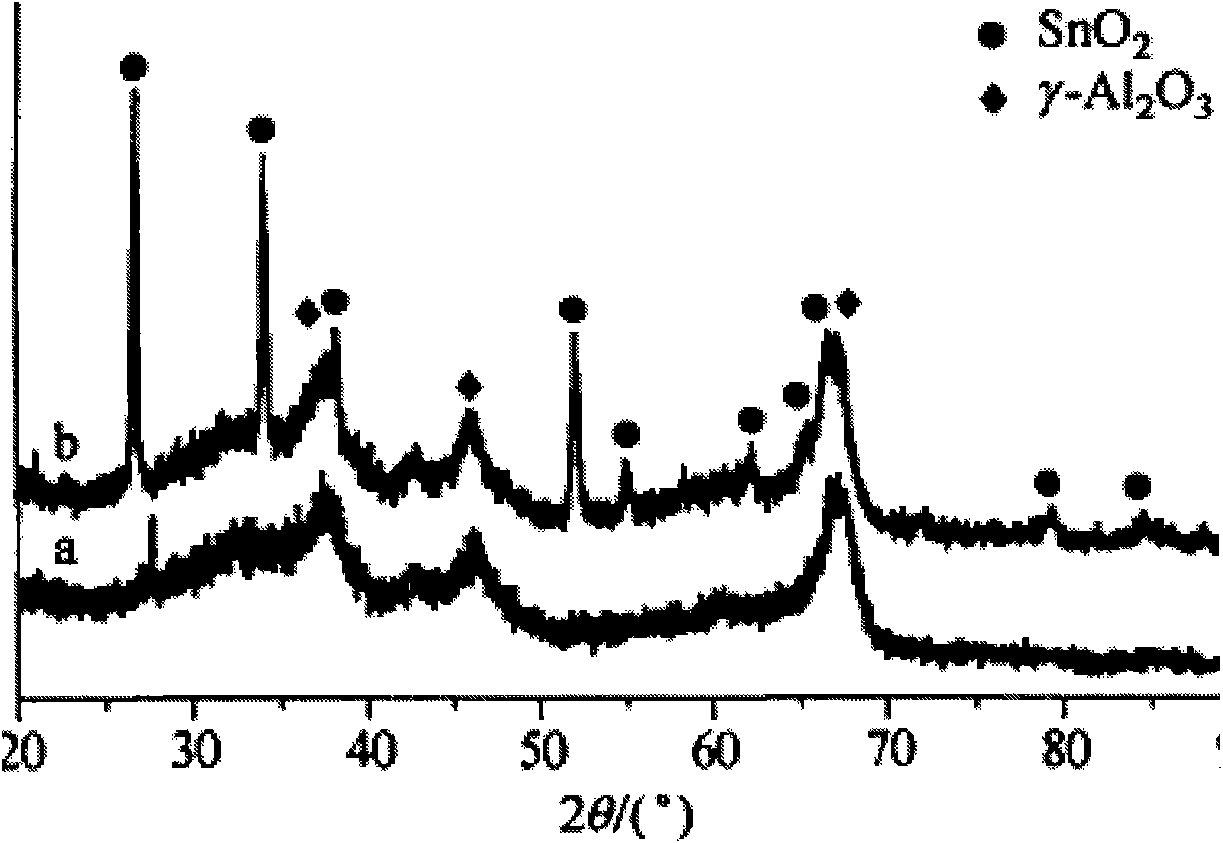

[0039] Use 1mol·L of raw activated carbon with a particle size of about 5mm -1 impregnated with NaOH solution at room temperature for 10 hours, then washed to neutrality, dried at 160°C for 2 hours, and cooled with 1mol L -1 HNO 3 The solution was impregnated and stirred at room tempera...

Embodiment 2

[0047] Main parameters and performance of high-frequency ultra-pulse power generator: output voltage: average voltage 0-36V, output square wave pulse frequency 5KHZ-10KHZ, output pulse duty cycle 25%≤d≤100%; output maximum average current 80A; The voltage, duty cycle, current, and frequency are continuously adjustable; the output voltage polarity control is required to be controlled within 10 seconds, and the maximum is not more than 10 seconds; display requirements: average voltage, peak voltage, current, frequency, and duty cycle; the line is Closed-loop design and requires overcurrent, overvoltage, current limiting, voltage limiting, overheating protection devices; soft start function.

[0048] Use 2mol·L of raw activated carbon with a particle size of about 5mm -1 The NaOH solution was impregnated and stirred at room temperature for 8 hours, then washed to neutrality, dried at 180°C for 1.5 hours, and then cooled with 1mol L -1 HNO 3 The solution was impregnated and stir...

Embodiment 3

[0056] Main parameters and performance of high-frequency ultra-pulse power generator: output voltage: average voltage 0-54V, output square wave pulse frequency 15KHZ-18KHZ, output pulse duty cycle 25%≤d≤100%; output maximum average current 80A; The voltage, duty cycle, current, and frequency are continuously adjustable; the output voltage polarity control is required to be controlled within 10 seconds, and the maximum is not more than 10 seconds; display requirements: average voltage, peak voltage, current, frequency, and duty cycle; the line is Closed-loop design and requires overcurrent, overvoltage, current limiting, voltage limiting, overheating protection devices; soft start function.

[0057] Use 1mol·L of raw activated carbon with a particle size of about 5mm -1 The NaOH solution was impregnated and stirred at room temperature for 8 hours, then washed to neutrality, dried at 200°C for 1 hour, and then cooled with 1mol L -1 HNO 3 The solution was impregnated and stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com