Preparation method of nano silicon dioxide powder

A technology of nano-silica and powder, which is applied in the field of nano-materials, can solve the problems of easy agglomeration and growth of primary particles, low purity of products, complex combustion process, etc., achieve good dispersion, shorten the preparation cycle, and prepare short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of nano silicon dioxide powder body, comprises the following steps:

[0020] 1) Dissolve 192.14g (1mol) of citric acid in 300ml of ammonia water with a volume concentration of 25%, then add ethyl orthosilicate according to the molar ratio of ethyl orthosilicate: citric acid = 1: 1.5, stir to make orthosilicate Dissolve ethyl acetate; then add 100ml of absolute ethanol and 64g of polyethylene glycol in turn, heat to 50°C and stir to dissolve completely; adjust the pH value to 5.0 with ammonia water to make a precursor, evaporate in a water bath at 80°C until white wet gel;

[0021] 2) drying and foaming the wet gel in a furnace at 130°C under an air atmosphere to obtain a dry gel;

[0022] 3) Put the xerogel into a kiln for calcination at a constant temperature of 600° C. under an air atmosphere, and take it out after calcination for 5 hours to obtain a loose amorphous nano-silica powder with a particle size of 10-20 nm.

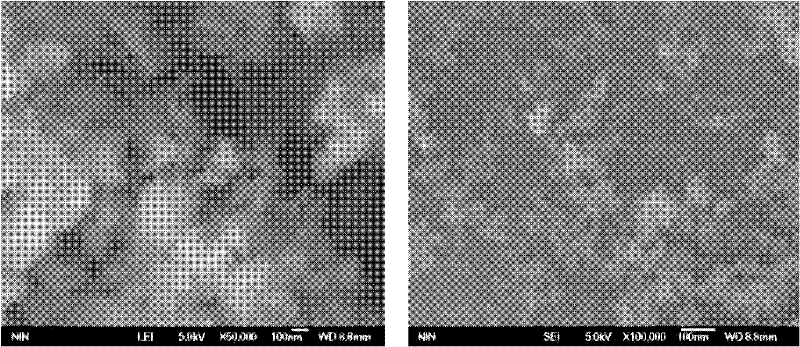

[0023] The SEM photogra...

Embodiment 2

[0025] The preparation method of nano silicon dioxide powder body, comprises the following steps:

[0026] 1) Dissolve 192.14g (1mol) of citric acid in 300ml of ammonia water with a volume concentration of 28%, then add ethyl orthosilicate according to the molar ratio of ethyl orthosilicate: citric acid = 1: 2.5, stir to make orthosilicate Dissolve ethyl acetate; then add 150ml of absolute ethanol and 96g of polyethylene glycol in turn, heat to 70°C and stir to dissolve completely; adjust the pH value to 8.0 with ammonia water to make a precursor, evaporate in a water bath at 90°C until white wet gel;

[0027] 2) drying and foaming the wet gel in a furnace at 140°C under an air atmosphere to obtain a dry gel;

[0028] 3) Put the xerogel into a kiln for calcination at a constant temperature of 900° C. under an air atmosphere, and take it out after calcination for 5 hours to obtain loose amorphous nano-silica powder with a particle size of 10-20 nm.

Embodiment 3

[0030] The preparation method of nano silicon dioxide powder body, comprises the following steps:

[0031] 1) Dissolve 192.14g (1mol) of citric acid in 300ml of ammonia water with a volume concentration of 25%, then add ethyl orthosilicate according to the molar ratio of ethyl orthosilicate: citric acid=1:2, stir to make orthosilicate Dissolve ethyl acetate; then add 120ml of absolute ethanol and 80g of polyethylene glycol in turn, heat to 65°C and stir to dissolve completely; adjust the pH value to 6.0 with ammonia water to make a precursor, evaporate in a water bath at 85°C until white wet gel;

[0032] 2) drying and foaming the wet gel in a furnace at 145°C under an air atmosphere to obtain a dry gel;

[0033] 3) Put the xerogel into a kiln for calcination at a constant temperature of 800° C. under an air atmosphere, and take it out after calcination for 4 hours to obtain loose amorphous nano-silica powder with a particle size of 10-20 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com