Silicon-containing sodium aluminate solution deep desiliconization method

A sodium aluminate and solution technology, which is applied in the purification of aluminate/alumina/aluminum hydroxide and the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problem that the desiliconization depth of the desilication agent is not high. , large loss of alumina, consumption of caustic soda and other problems, to achieve the effect of improving the surrounding environment, realizing reuse, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

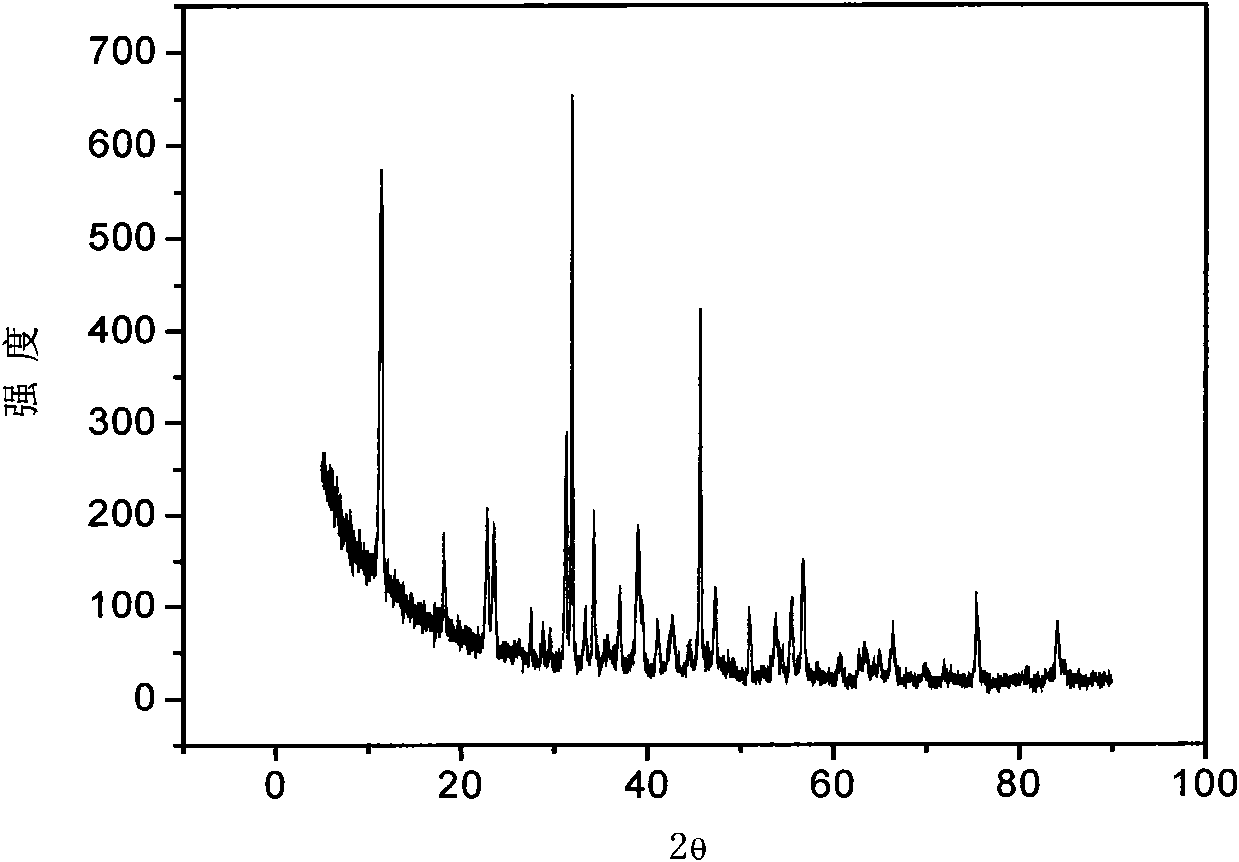

Image

Examples

Embodiment 1

[0025] (1) the waste calcium chloride in the chlor-alkali industry is dissolved in water, and is made into the solution that concentration is 0.5mol / L;

[0026] (2) Add sodium hydroxide and aluminum hydroxide to water, heat to dissolve the sodium hydroxide and aluminum hydroxide to obtain a sodium aluminate solution; wherein, the Na in the sodium aluminate solution 2 O and Al 2 o 3 The molar ratio of is 1.5;

[0027] (3) 300ml of sodium aluminate solution prepared in step (2) is added in the reaction tank with jacket, and in the jacket of the reaction tank with jacket, pass into circulating oil bath, the sodium aluminate solution Adjust the temperature to 50°C, and at a stirring speed of 200rpm, add 300ml of the calcium chloride solution prepared in step (1) into the reaction tank to control the chloride content in the mixed solution of calcium chloride and sodium aluminate in the reaction tank. The molar ratio of calcium to sodium aluminate is 8, the reaction temperature i...

Embodiment 2

[0035] (1) the waste calcium chloride in the chlor-alkali industry is dissolved in water, and is made into the solution that concentration is 0.5mol / L;

[0036] (2) Add sodium hydroxide and aluminum hydroxide to water, heat to dissolve the sodium hydroxide and aluminum hydroxide to obtain a sodium aluminate solution; wherein, the Na in the sodium aluminate solution 2 O and Al 2 o 3 The molar ratio of is 1.5;

[0037] (3) 300ml of sodium aluminate solution prepared in step (2) is added in the reaction tank with jacket, and in the jacket of the reaction tank with jacket, pass into circulating oil bath, the sodium aluminate solution Adjust the temperature to 100°C, and at a stirring speed of 200rpm, add 300ml of the calcium chloride solution prepared in step (1) into the reaction tank to control the chloride content in the mixed solution of calcium chloride and sodium aluminate in the reaction tank. The molar ratio of calcium to sodium aluminate is 6, the reaction temperature ...

Embodiment 3

[0045] (1) the waste calcium chloride in the chlor-alkali industry is dissolved in water, is made into the solution that concentration is 1mol / L;

[0046] (2) Add sodium hydroxide and aluminum hydroxide to water, heat to dissolve the sodium hydroxide and aluminum hydroxide to obtain a sodium aluminate solution; wherein, the Na in the sodium aluminate solution 2 O and Al 2 o 3 The molar ratio of is 3.2;

[0047] (3) 300ml of sodium aluminate solution prepared in step (2) is added in the reaction tank with jacket, and in the jacket of the reaction tank with jacket, pass into circulating oil bath, the sodium aluminate solution Adjust the temperature to 30°C, and at a stirring speed of 500rpm, add 300ml of the calcium chloride solution prepared in step (1) into the reaction tank to control the chloride content in the mixed solution of calcium chloride and sodium aluminate in the reaction tank. The molar ratio of calcium to sodium aluminate is 10, the reaction temperature is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com