Pollution-free recycling method of iron-based grinding waste material

A non-polluting technology for grinding waste, applied in the field of circular economy, can solve the problem of high cost of raw materials, and achieve the effects of high recycling rate, increasing thickness, and suppressing reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

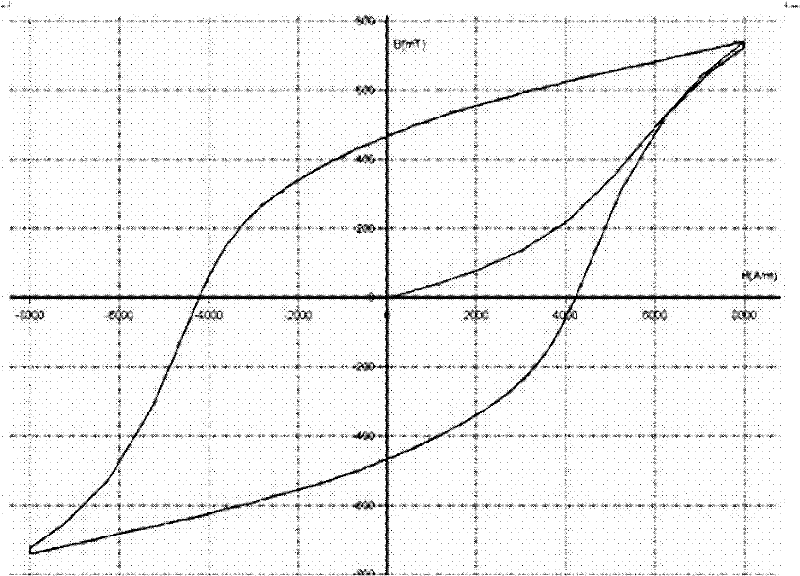

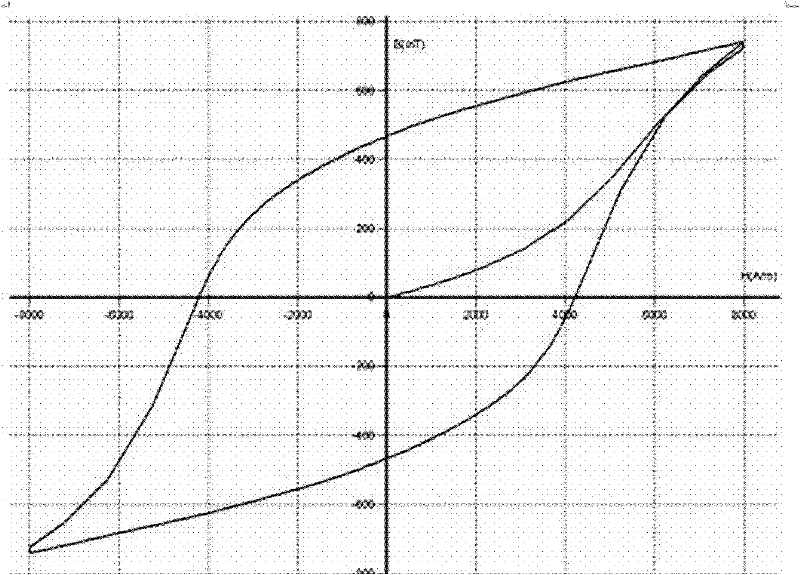

Image

Examples

Embodiment 1

[0040] The iron-based grinding waste and the surfactant sodium octyl sulfonate are uniformly mixed, and the mass ratio thereof is iron-based grinding waste: sodium octyl sulfonate is 100:1. After mixing evenly, add water to the mixed powder, stir and wash thoroughly. The washed grinding waste was taken out and baked in an oven at 200° C. for 2 hours to obtain iron-based alloy powder with TFe%=81.6%.

Embodiment 2

[0042] The iron-based grinding waste and the surfactant sodium octyl sulfonate are uniformly mixed, and the mass ratio thereof is iron-based grinding waste: sodium octyl sulfonate is 100:3. After mixing evenly, add water to the mixed powder, stir and wash thoroughly. The washed grinding waste was taken out and baked in an oven at 800° C. for 0.5 h to obtain iron-based alloy powder with TFe%=70.2%.

Embodiment 3

[0044] The iron-based grinding waste and the surfactant sodium octyl sulfonate are uniformly mixed, and the mass ratio thereof is iron-based grinding waste: sodium octyl sulfonate is 100:1. After mixing evenly, add water to the mixed powder, stir and wash thoroughly. The washed grinding waste was taken out and baked in an oven at 200°C for 2 hours to obtain an iron-based alloy powder with TFe%=81.6%, which was sieved to obtain -40~+400 mesh iron-based alloy powder. Mix the reducing agent Al powder and the sieved iron-based alloy powder evenly with a mass ratio of 1:3; put the mixed powder as the raw material of the SHS-lined steel pipe into a steel pipe with a diameter of 80 mm, a wall thickness of 4 mm, and a length of 150 mm. Fix the steel pipe on the pipe making machine, start the pipe making machine, and ignite the material with tungsten wire. After the reaction, a ceramic coating with a smooth surface and no cracks is formed on the inner wall of the steel pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com