CSP process-based manufacturing method of economical hot-rolled dual-phase steel with high surface quality

A technology of hot-rolled dual-phase steel and a manufacturing method, which is applied to workpiece surface treatment equipment, metal rolling, manufacturing tools, etc. Stable control of tissue properties, prevention of iron oxide scale defects, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

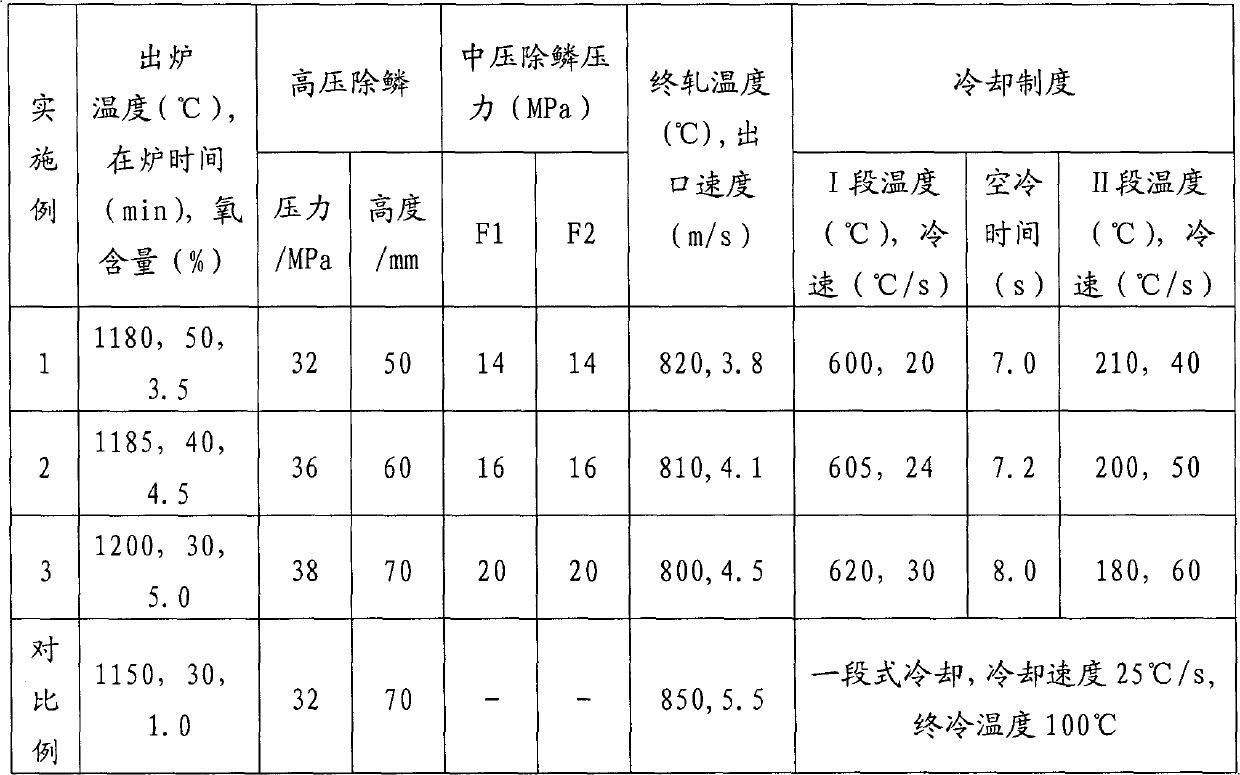

[0029] 1) The chemical composition of the steels in Examples 1-3 and Comparative Example is shown in Table 1.

[0030] Table 1 Melting composition of Examples 1-3 and Comparative Example (wt, %)

[0031] Example

[0032] The steel of the chemical composition of Examples 1 to 3 listed in Table 1 is taken as a raw material through molten iron desulfurization, converter blowing, argon blowing, LF furnace refining, continuous casting, and rotary descaling device descaling (produced by SMS company in Germany, Example 1-3 Control rotary descaling pressure (45MPa, 43MPa, 40MPa respectively), soaking furnace soaking, high pressure descaling, finishing rolling (medium pressure descaling at the exit of F1 and F2), two-stage cooling, coiling Steel plates with a thickness specification of 4 to 6 mm. The comparative example adopts the conventional process to obtain steel plates with a thickness specification of 4-6 mm through desulfurization of molten iron, converter blowing, ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com